Environmentally-friendly weather and aging resistant flame-retardant resin composition and preparation method thereof

A flame-retardant resin and anti-aging technology, which is applied in the field of polymer materials and its manufacturing, can solve problems such as expensive, unsuitable for outdoor use, and material performance degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

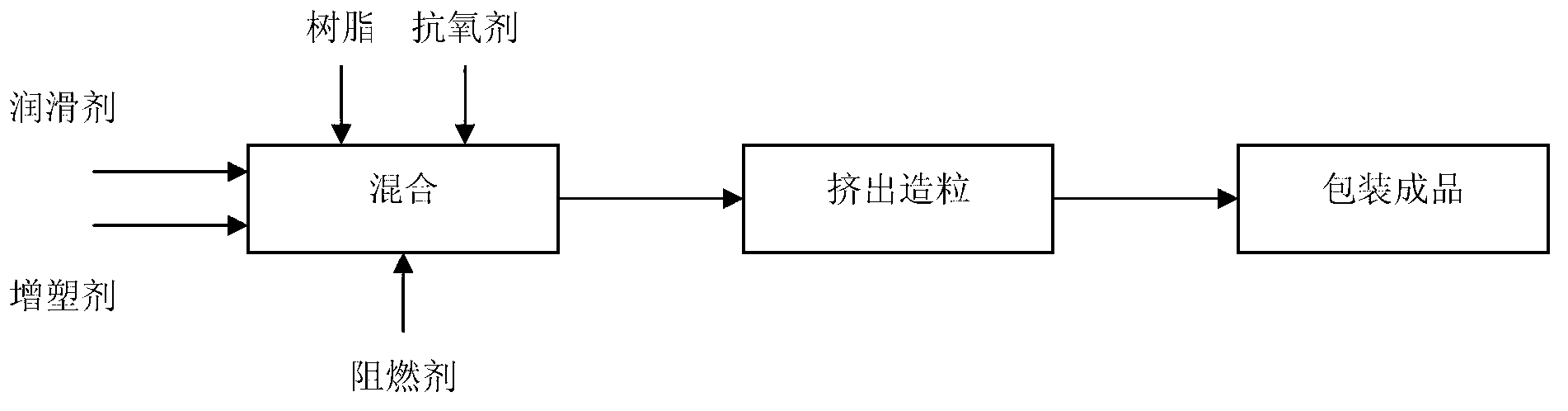

[0026] A preparation method of the above-mentioned environment-friendly weather-resistant anti-aging flame retardant resin composition is characterized in that: it comprises the following preparation steps (such as figure 1 ):

[0027] First, add chlorinated polyethylene rubber grafted with butyl acrylate, styrene, and N-phenylmaleimide resin into the high-mixer and mix. The temperature is set at room temperature to 60°C. Plasticizer, continue mixing; when the temperature is 70°C-80°C, add antioxidant and lubricant; when the temperature is ≥80°C, add flame retardant, continue mixing, and cool and discharge when the temperature is ≤120°C;

[0028] Then, set the extrusion granulation temperature in the following sections: first section 160°C, second section 185°C, third section 200°C, fourth section 210°C, fifth section 200°C, sixth section 195°C , the seventh section is 205°C. The speed of the main machine is set at 250-300r / min; when the temperature reaches the set temperatu...

Embodiment 1

[0040] 100 parts by weight of chlorinated polyethylene rubber graft copolymer resin, 0.002 part of antioxidant (1076, 246 or TNPP), 0.05 part of plasticizer (DOP, TCP, or EPO), lubricant (polyethylene wax , or calcium stearate) 0.003 parts, flame retardant (brominated polystyrene, zinc borate, or hydrotalcite) 0.15 parts, according to the above at different temperatures were added to the high mixer for mixing, and then added Extrusion granulator, extrusion granulation at 160℃~210℃. The pellets were made into standard splines. After testing, the flame retardancy reaches FV-O, and other properties are good. The impact strength is 180J / m, the tensile strength is 64.0Mpa, and the bending strength is 85Mpa. The bending modulus is 3421.3, and the hardness is HR107.

[0041] Wherein: the preparation method of chlorinated polyethylene rubber graft copolymerization resin is as follows:

[0042] Raw material and weight ratio: chlorinated polyethylene rubber: butyl acrylate: acrylonit...

Embodiment 2

[0045] 100 parts (by weight) of chlorinated polyethylene rubber graft copolymer resin base material, 0.02 parts of antioxidant (1010, 3114, or 168), 0.02 parts of plasticizer (610, EPE, or TIOTM), lubricant ( EPS, or E wax) 0.05 parts, flame retardant (brominated epoxy resin, antimony trioxide, or aluminum hydroxide) 0.02 parts. According to the above, add the high-mixer at different set temperatures, and after mixing evenly, extrude and granulate at a temperature of 160°C to 210°C. The pellets are made into standard test strips, and the flame retardancy is tested to reach FV-O, and other properties are good. The notched impact strength is 250J / M, the tensile strength is 58Mpa, the bending strength is 81Mpa, and the heat distortion temperature is 92°C. The elongation at break is 25%.

[0046] Wherein: the preparation method of chlorinated polyethylene rubber graft copolymerization resin is as follows:

[0047] Raw material and weight ratio: chlorinated polyethylene rubber: b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com