Chlortetracycline premix and preparation method thereof

The technology of a premix and chlortetracycline hydrochloride is applied in the direction of pharmaceutical formulations, additional food elements, tetracycline active ingredients, etc. It can solve the problems of easy decomposition, easy generation of dust, and fast release speed, so as to reduce the heat and humidity process and increase production capacity. consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

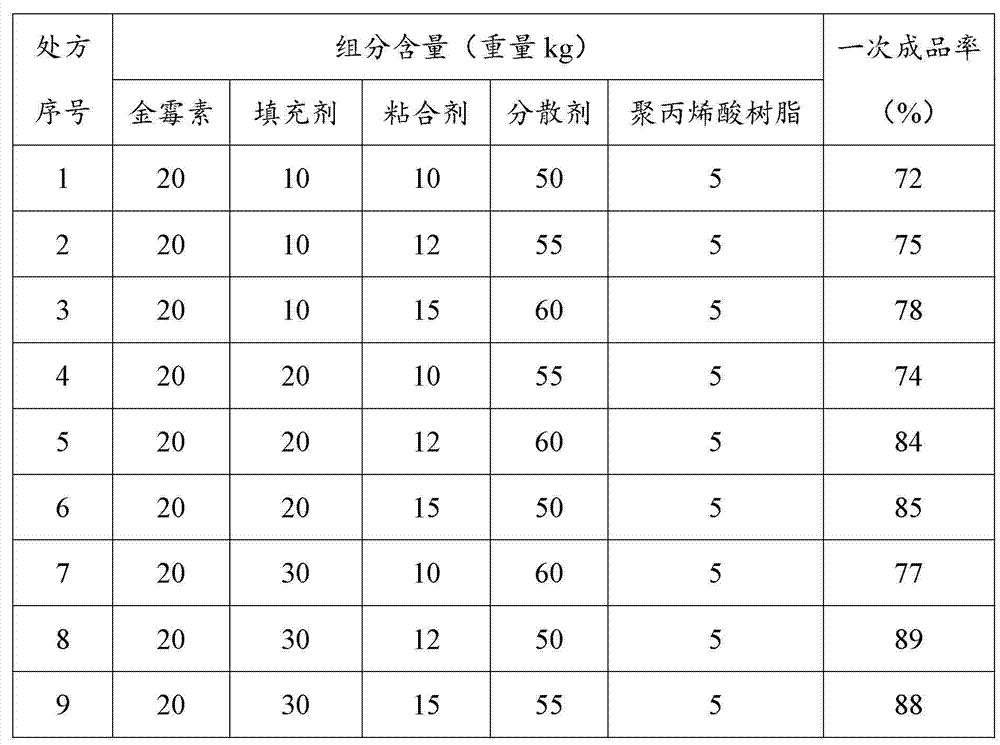

Method used

Image

Examples

Embodiment 1

[0025] Mix 50Kg aureomycin hydrochloride and 300Kg calcium carbonate ultra-fine powder together (calcium carbonate can pass through 800 mesh sieve), mix the mixed powder with 60Kg corn starch, 15Kg microcrystalline cellulose, 45Kg dextrin, 25Kg polyacrylic acid Resin powder (weight ratio, polyacrylic resin No. II: polyacrylic resin No. III = 3:2) was stirred for 30 minutes, and the mixture was compressed into tablets by a tablet machine. Then it is pulverized and sieved by a pulverizer, wherein the particles that have not passed through the 20 mesh sieve continue to be crushed, and the particles smaller than the 60 mesh sieve are returned to tableting. The remaining 20-mesh sieve but not 30-mesh sieve particles and the 30-mesh sieve but not 60-mesh sieve particles are required finished products, and the product 455Kg is obtained, and the first-time yield is 91%.

[0026] Get a sample detection content by interval 70kg from present embodiment, content detection result is as fol...

Embodiment 2

[0029] Mix 100Kg aureomycin hydrochloride and 250Kg calcium carbonate fine powder together (calcium carbonate can pass through 800 mesh sieve), mix the mixed powder with 75Kg corn starch, 25Kg microcrystalline cellulose, 50Kg dextrin, 25Kg polyacrylic acid Resin powder (weight ratio, polyacrylic resin No. II: polyacrylic resin No. III = 3:2) was stirred for 30 minutes, and the mixture was compressed into tablets by a tablet machine. Then it is pulverized and sieved by a pulverizer, wherein the particles that have not passed through the 20 mesh sieve continue to be crushed, and the particles smaller than the 60 mesh sieve are returned to tableting. Remaining 20-mesh sieve but not 30-mesh sieve particles and 30-mesh sieve-less 60-mesh sieve particles are the desired finished products, and the product 431Kg is obtained, and the primary yield is 86.2%.

[0030] Get a sample detection content by interval 70kg from present embodiment, content detection result is as following table: ...

Embodiment 3

[0033] Mix 50Kg aureomycin hydrochloride and 300Kg calcium carbonate fine powder together (calcium carbonate can pass through 800 mesh sieve), mix the powder after mixing with 60Kg cornstarch, 60Kg dextrin, 25Kg polyacrylic acid resin powder (weight ratio, Polyacrylic resin No. II: Polyacrylic resin No. III = 1:1) After stirring for 30 minutes, the mixture was compressed into tablets by a tablet machine. Then it is pulverized and sieved by a pulverizer, wherein the particles that have not passed through the 20 mesh sieve continue to be crushed, and the particles smaller than the 60 mesh sieve are returned to tableting. Remaining 20-mesh sieve but not 30-mesh sieve particles and 30-mesh sieve-less 60-mesh sieve particles are required finished products, and the product 407Kg is obtained, and the first-time yield is 81.4%.

[0034] Get a sample detection content by interval 70kg from present embodiment, content detection result is as following table:

[0035] Sample ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com