Waterborne organic and inorganic fluorosiloxane modified acrylate polymer emulsion and preparation method and application thereof

A polymer emulsion and acrylate technology, applied in the direction of coating, can solve the problems of affecting the final performance of the coating film, cumbersome interfacial force, unfavorable industrialization, etc., and achieve a simple and feasible preparation method, high wear resistance, high hardness, and excellent resistance. heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

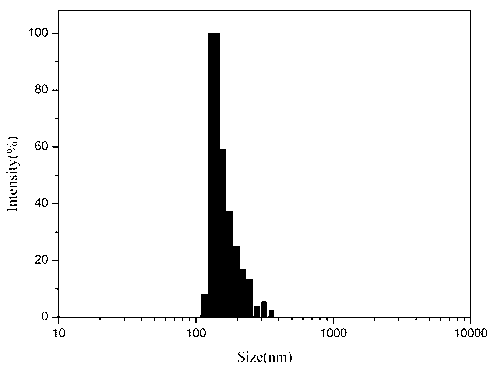

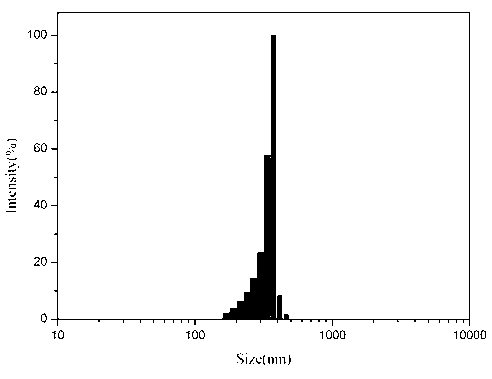

Image

Examples

Embodiment 1

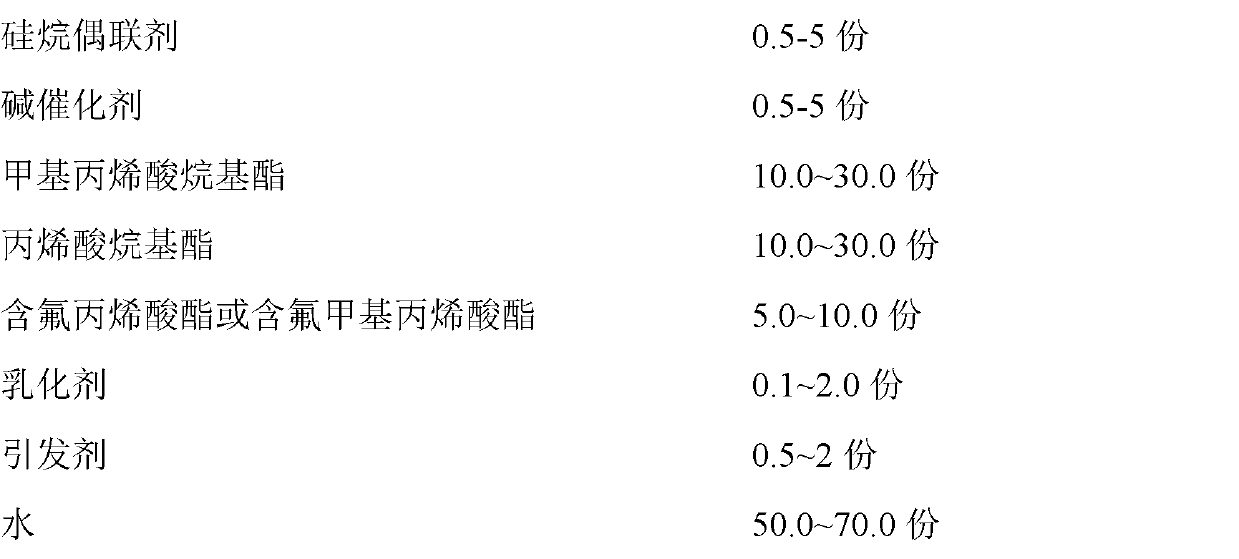

[0036] (1) In parts by weight, weigh each component according to parts by weight in Table 1;

[0037] Table 1:

[0038]

[0039] Methyl methacrylate, butyl acrylate and dodecafluoroheptyl methacrylate are prepared into mixed monomer I copolymer, the glass transition temperature of mixed monomer I copolymer is about -5 °C, and 1.0 part of initiator is over Potassium sulfate was dissolved in 15 parts of water to make an initiator solution.

[0040] (2) Add 3 parts of ammonia water, 0.5 parts of emulsifier SDS, 1.0 part of OP-10 and 50 parts of water into the reaction kettle, stir for 20 minutes and then raise the temperature to 50 ℃. Then, 2 parts of γ-methacryloxypropyltrimethoxysilane were added in 0.5 hours, and reacted for 12 hours to obtain a product solution.

[0041] (3) Warm up the product solution obtained in step (2) to 78°C, then add the mixed monomer I and initiator solution in step (1) dropwise to the heated step (2) product solution in 3 hours, drop After the...

Embodiment 2

[0046] (1) In parts by weight, weigh each component according to parts by weight in Table 2;

[0047] Table 2:

[0048]

[0049] Methyl methacrylate, ethyl methacrylate, butyl acrylate, pentyl acrylate, and dodecafluoroheptyl acrylate are used to make mixed monomer I copolymers, and the glass transition temperature of mixed monomer I copolymers is about -10 °C , and 1.5 parts of initiator sodium persulfate was dissolved in 20 parts of water to make initiator solution.

[0050] (2) Add 2 parts of sodium hydroxide, 0.7 parts of DSB, 1.0 part of OP-30 and 50 parts of water into the reaction kettle, stir for 30 minutes and then raise the temperature to 55 ℃. Then, 3 parts of vinyltriethoxysilane were added in 1 hour, and reacted for 18 hours to prepare a product solution.

[0051] (3) Warm up the product solution prepared in step (2) to 80°C, then add the mixed monomer I and initiator solution prepared in step (1) dropwise to the product solution in step (2) after heating up ...

Embodiment 3

[0056] (1) In parts by weight, weigh each component according to parts by weight in Table 3;

[0057] table 3:

[0058]

[0059] Ethyl methacrylate, propyl methacrylate, methyl acrylate and tridecafluorooctylethyl acrylate are made into mixed monomer I copolymer, and the glass transition temperature of mixed monomer I copolymer is about 30 °C, and 0.9 parts of initiator ammonium persulfate was dissolved in 10 parts of water to make initiator solution.

[0060] (2) Add 1.8 parts of potassium hydroxide, 0.4 parts of LAS, 0.8 parts of NP-15 and 50 parts of water into the reaction kettle, stir for 15 minutes and then raise the temperature to 45 °C. Then, 1.8 parts of vinyltrimethoxysilane was added in 0.5 hours, and reacted for 24 hours to prepare a product solution.

[0061] (3) Warm up the product solution prepared in step (2) to 76°C, then add the mixed monomer I and initiator solution prepared in step (1) dropwise to the product solution in step (2) after heating up in 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com