Method for preparing diglyceride through goose fat enzymolysis

A technology of diglyceride and goose oil, which is applied in the field of enzymatic hydrolysis of goose oil to prepare diglyceride, which can solve the problems of goose oil waste and less goose oil, and achieve the effects of increasing yield, sufficient reaction, and shortening filtration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] 2) Preparation of mixed fatty acids: add the refined goose oil to 1mol / L NaOH-ethanol solution at a volume ratio of 1:4, stir magnetically for a period of time to completely dissolve it, then transfer it to a 1000ml three-necked flask, and reflux in a water bath under nitrogen protection Saponify for a period of time to obtain a saponified solution; distill ethanol out under reduced pressure, add water to completely dissolve the saponified product, acidify with 10% HCl to pH 2-3 under constant temperature and constant speed stirring, add a certain volume of n-hexane for extraction, and wash with warm water until Neutral, evaporate the solvent under reduced pressure, add anhydrous sodium sulfate for dehydration, and filter with suction to obtain mixed fatty acids. This not only makes the reaction more fully, but also shortens the reaction time to a certain extent, and improves the diglyceride formation rate. Among them, the preparation conditions of the mixed fatty acid ...

Embodiment 1

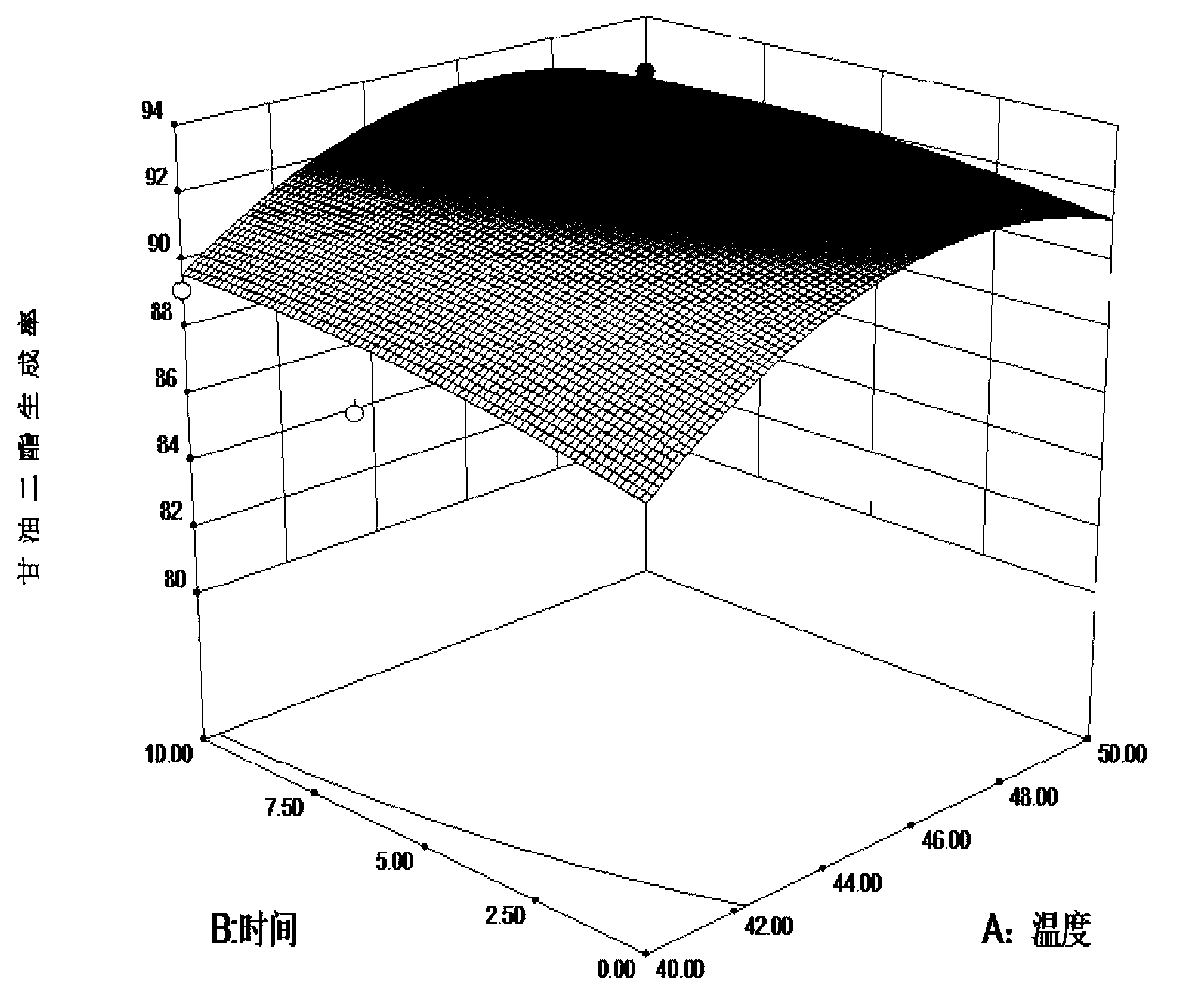

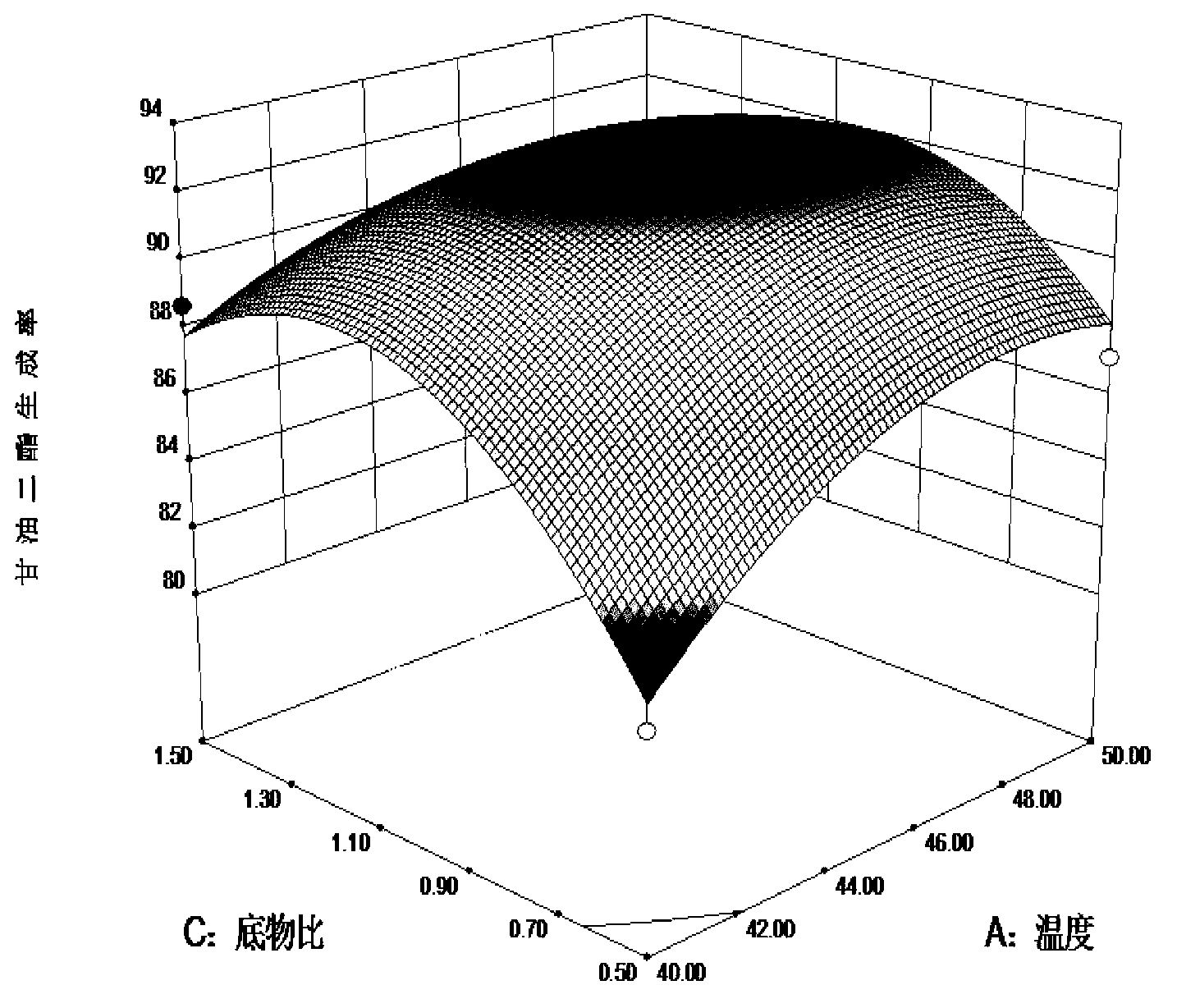

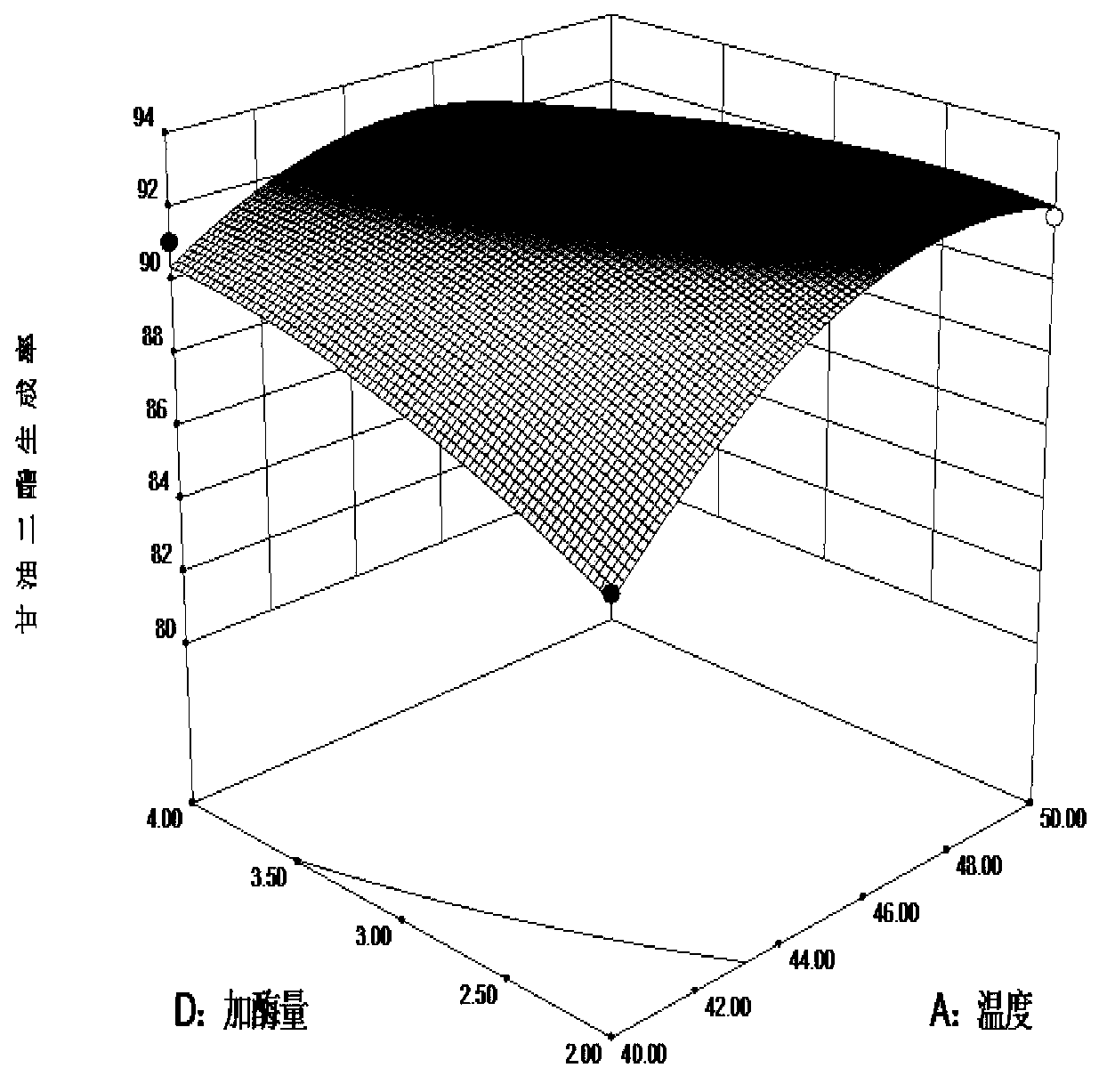

[0034] Example 1: Screening test for the optimum process conditions for the preparation of diglycerides from enzymatic hydrolysis of goose oil

[0035] 1. Refining of goose oil

[0036] The fat liver and goose belly fat is heated at 55°C to melt, and the impurities are removed by vacuum filtration to obtain crude goose oil; the crude goose oil is degummed, decolorized, and deodorized to obtain refined goose oil products.

[0037] 2. Preparation of mixed fatty acids

[0038] Add the refined goose oil to 1mol / L NaOH-ethanol solution in a ratio of 1:4, stir magnetically for a period of time to completely dissolve it, then transfer it to a 1000ml three-necked flask, and reflux it in a water bath at 82°C for 1 hour to obtain a saponified solution. In a rotary evaporator, evaporate ethanol under reduced pressure, add water to completely dissolve the saponified product, acidify with 10% HCl to pH 2-3 under constant temperature and constant speed stirring, separate layers, add a cert...

Embodiment 2

[0057] Example 2: Enzymatic hydrolysis of goose oil to prepare diglyceride optimal process conditions screening regression test one

[0058] Add glycerol and mixed fatty acids directly into the flask at a substrate ratio of 1:1.05, place on a constant shaker, and set the reaction temperature at 50°C. After the reactants are evenly mixed, add 2.25% mass fraction of Candida antarctica Lipase B, the reaction time is 9.2h. After the reaction is completed, centrifuge the enzymatic solution in a high-speed centrifuge for 10 minutes to separate the enzyme. The supernatant is a mixture of high diglycerides. generation rate. Through 5 verification tests, it was found that the production rate of diglyceride obtained under this condition was 92.05%, 92.37%, 92.28%, 92.25%, 92.34%, and the average extraction rate was 92.26%, which was basically consistent with the results of Example 1; The above results show that the process of the present invention has good stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com