Carbon glue embedded resistance paste and preparation method of carbon glue embedded resistance material

A technology of buried resistance and carbon glue is applied in the field of preparation of graphite/epoxy resin type resistance paste compound, which can solve the problems affecting the performance of embedded resistance circuit boards, poor stability of resistance value of carbon glue resistance, etc. The effect of good thermal and storage stability, excellent mechanical properties, and excellent thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

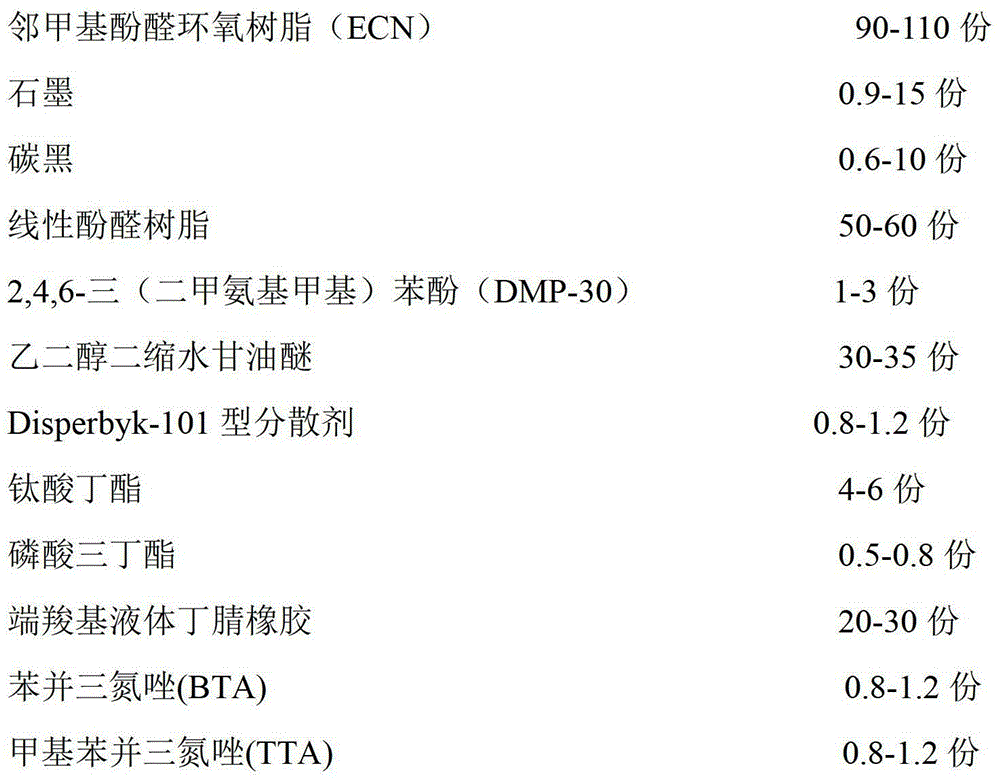

[0032] The formula is as follows:

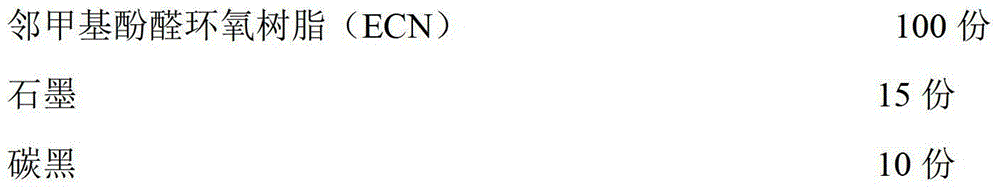

[0033]

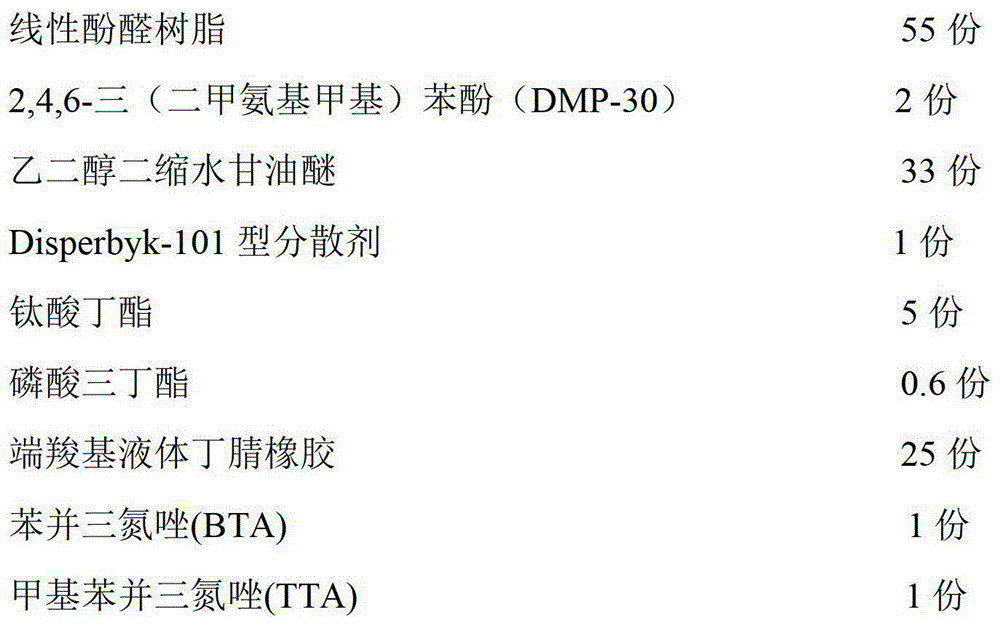

[0034]

[0035] According to the above formula, the preparation and curing of carbon rubber resistor paste are completed according to the following process:

[0036] (1). Add 15g of graphite / 10g of carbon black mixture into the 5% butyl titanate (5g) solution prepared in alcohol, stir well until the solvent evaporates; at the same time, weigh 100g of o-methyl novolac epoxy resin (ECN ), 33g of ethylene glycol diglycidyl ether and 25g of carboxyl-terminated liquid nitrile rubber were soaked in a constant temperature water bath at 80°C for 1h; (2). The graphite / carbon black conductive powder treated with the coupling agent was placed in a vacuum oven Dry at 110°C for 1 hour; at the same time, quickly stir the resin solution with electric agitator for 1 hour; (3). Add the dried graphite / carbon black conductive powder to the rapidly stirred resin solution several times, and at the same time, add a small amount of other additives ...

Embodiment 2

[0046] The difference between this example and Example 1 is only that: the addition of graphite / carbon black is changed to 3 parts / 2 parts, and other components are unchanged. The performance of the cured resistance sample strip obtained by testing is as follows:

[0047] Resistivity: 650Ω.cm;

[0048] Square resistance accuracy error: ≤10%;

[0049] Moisture and heat resistance: after 85%RH / 85℃ / 500 hours, the change of resistance value is less than 10%;

[0050] Solder resistance: 260℃ / 5s / 3 times, resistance change is less than 10%;

[0051] Temperature coefficient of resistance (TCR): TCR≤200ppm / ℃;

[0052] Slurry storage period (at room temperature): ≥12 months;

[0053] Bending strength: 76.53MPa;

[0054] Bending strain: 1.83%.

Embodiment 3

[0056] The difference between this example and Example 1 is only that: the addition of graphite / carbon black is changed to 0.9 part / 0.6 part, and other components are unchanged, and the performance of the obtained cured object resistance sample strip is as follows:

[0057] Resistivity: 1900Ω.cm;

[0058] Square resistance accuracy error: ≤10%;

[0059] Moisture and heat resistance: after 85%RH / 85℃ / 500 hours, the change of resistance value is less than 10%;

[0060] Solder resistance: 260℃ / 5s / 3 times, resistance change is less than 10%;

[0061] Temperature coefficient of resistance (TCR): TCR≤200ppm / ℃;

[0062] Slurry storage period (at room temperature): ≥12 months;

[0063] Bending strength: 70.42MPa;

[0064] Bending strain: 1.68%.

[0065] From the above three examples, it can be seen that according to the above formulations, the resistance of the cured carbon glue with accurate resistance, stability and excellent mechanical properties can be obtained. The resistance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| temperature coefficient of resistance | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com