Method for performing ozone catalysis-coupled biological nitrification treatment on acrylonitrile wastewater

A technology for the catalytic oxidation of acrylonitrile wastewater and ozone, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Realize the effective removal of ammonia nitrogen and other problems, and achieve the effect of enhancing the impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

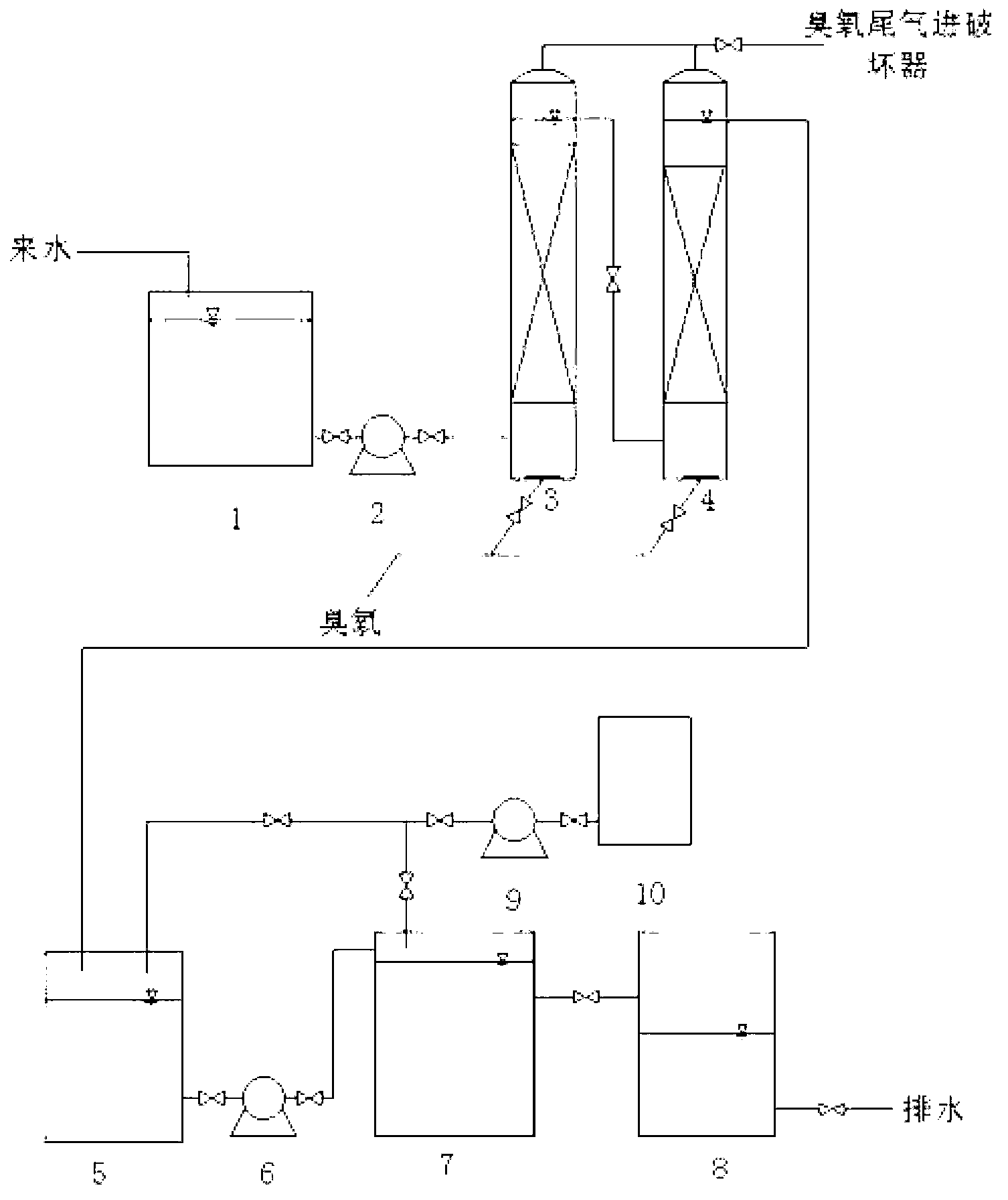

Image

Examples

Embodiment 1

[0021] The acrylonitrile wastewater of a refinery company is 2400 m3 / d, which is currently treated by a secondary biochemical process. The results show that the existing process has no effect on ammonia nitrogen removal. On the contrary, due to biochemical hydrolysis, organic nitrogen is converted into ammonia nitrogen, resulting in a much higher ammonia nitrogen in the effluent In the influent ammonia nitrogen. In addition, because the influent water contains a large amount of refractory organic matter, the COD of the effluent has exceeded the standard. Therefore, it is planned to adopt the process method of ozone catalytic oxidation coupled with biological nitrification of the present invention, add an advanced treatment unit on the basis of the original secondary biochemical treatment process, and carry out a field pilot test with a scale of 15m3 / d.

[0022] The pre-oxidation tower is filled with stainless steel Pall ring packing, and the catalytic oxidation tower is filled...

Embodiment 2

[0025] The acrylonitrile waste water of a refinery company is 2000m3 / d, and the SBR process is currently used for biochemical treatment. The biochemical effluent contains a certain concentration of ammonia nitrogen, and the COD occasionally fails to meet the standard. Using the process method of ozone catalytic oxidation coupled with biological nitrification of the present invention, the company's biochemical effluent was carried out for 16 m 3 / d pilot test to solve the problem of wastewater discharge standards.

[0026] The pre-oxidation tower is filled with stainless steel Pall rings, and the catalytic oxidation tower is filled with columnar activated carbon and γ-Al 2 o 3 It is a mixture of carrier heterogeneous catalysts; the dosage of ozone in wastewater is (10-100) mg / L, and the residence time of the ozone oxidation tower is (0.25-1) h. The nitrification tank adopts the form of BAF, and the hydraulic retention time is 6h. Add sodium carbonate and sodium hydroxide mi...

Embodiment 3

[0029] The acrylonitrile wastewater of a petrochemical company is 9600 m3 / d, which is currently treated by pure oxygen aeration and biological contact oxidation process. The biochemical effluent has a high COD and contains a certain concentration of ammonia nitrogen. A small-scale test was carried out on the company's biochemical effluent by using the process method of ozone catalytic oxidation coupled with biological nitrification of the present invention, as an engineering basis for the transformation of the company's sewage treatment system.

[0030] The pre-oxidation tower is filled with θ ring packing, and the catalytic oxidation tower is filled with columnar activated carbon as a catalyst; the ozone dosage of wastewater is (100-200) mg / L, and the residence time in the ozone oxidation tower is (1-2 ) h. The nitrification tank adopts the form of BAF, and the hydraulic retention time is 3h. Add sodium hydroxide solution in the ozone removal tank to control the pH value in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com