Single-component deoximation type sealing adhesive for solar module

A solar module and sealant technology, applied in the field of sealant, can solve problems such as difficult to meet the requirements of solar modules, flame retardancy, sealing, environmental protection, curing speed, and insufficient aging, and achieve shortening of deep curing time and high temperature. High-humidity anti-aging performance is excellent, and the effect of not corroding metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

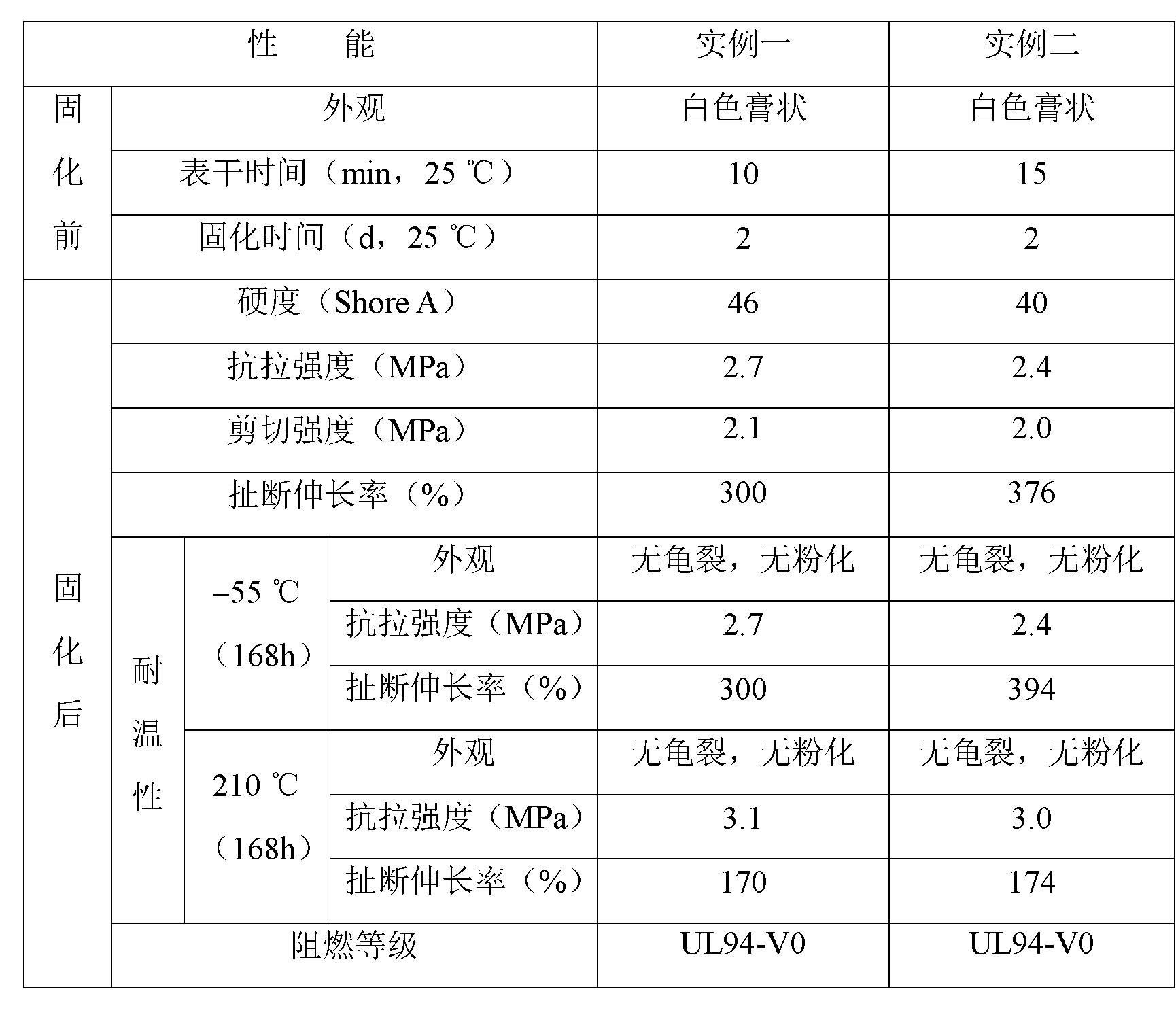

Embodiment 1

[0025] 100 parts of α, ω-dihydroxy polydimethoxysilane with a viscosity of 20000cps, 10 parts of dimethyl silicone oil with a viscosity of 100cps, 60 parts of nano calcium carbonate with a particle size of 40nm, and a specific surface area of 200m 2 5 parts / g of fumed white carbon black, 20 parts of aluminum hydroxide with a particle size of 2.5um, and 20 parts of melamine cyanurate flame retardant are put into a power mixer together and started to stir. Stir in vacuum for 80 minutes under the condition of -0.09MPa, and cool to obtain the base material; Parts, 1.5 parts of γ-aminopropyltriethoxysilane, 0.5 parts of γ-(methacryloyloxy)propyltrimethoxysilane, 0.5 parts of zirconium n-butoxide catalyst, adding the power In the mixer, stir for 80 minutes at a vacuum degree of -0.09MPa to obtain a one-component deoximation type sealant for solar modules.

Embodiment 2

[0027] 100 parts of α, ω-dihydroxy polydimethoxysilane with a viscosity of 30000cps, 15 parts of simethicone oil with a viscosity of 500cps, 80 parts of nano-calcium carbonate with a particle size of 80nm, and a specific surface area of 150m 2 5 parts / g of fumed white carbon black, 20 parts of aluminum hydroxide with a particle size of 5um, and 10 parts of melamine cyanurate flame retardant are put into a power mixer together and started to stir at a temperature of 160°C and a vacuum degree of - Stir under vacuum for 100 minutes under the condition of 0.1MPa, and cool to obtain the base material; at room temperature, add 5 parts of methyl tributylketoxime silane, 3 parts of vinyl tributylketoxime silane, and 1 part of tetrabutylketoxime silane , 1.5 parts of γ-aminopropyltriethoxysilane, 1 part of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, 0.2 parts of catalyst n-butoxide zirconium, add the above base material In a dynamic mixer, under the condition of vacuum degree -0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com