Low temperature glass phosphor and preparation method thereof

A low-temperature glass and glass fluorescence technology, applied in the field of LED packaging materials, can solve problems such as aging, poor quality stability, and chromaticity drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

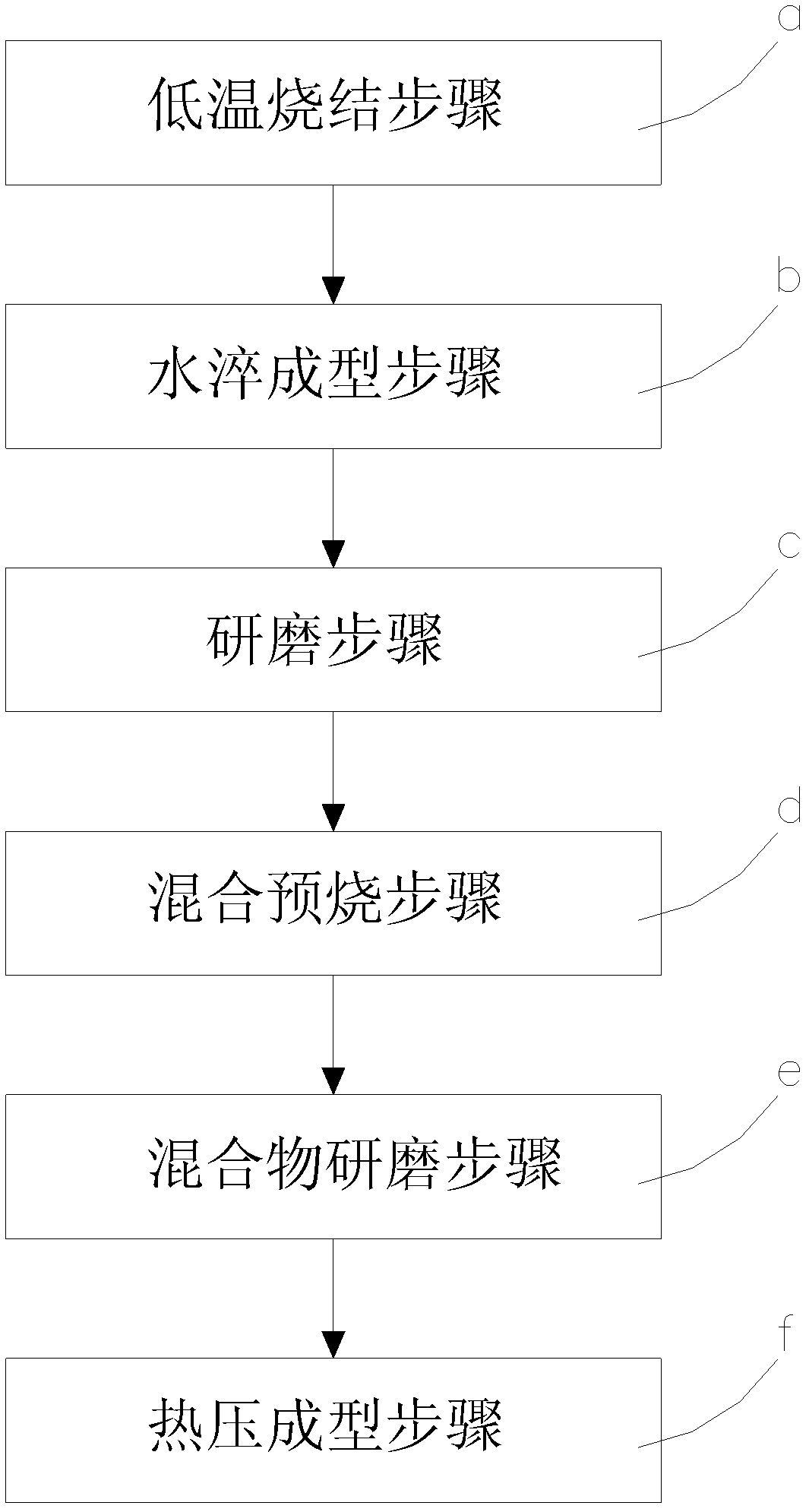

Method used

Image

Examples

Embodiment Construction

[0024] In the embodiment of the present invention, the formula and the preparation method of the low temperature glass phosphor will be described.

[0025] The low-temperature glass phosphor of the present invention includes low-temperature glass materials and fluorescent powder, wherein the fluorescent powder can be selected from fluorescent materials such as aluminate (YAG), silicate (Silicate), and nitride (Nitride). In this embodiment, , the phosphor is selected from yttrium aluminum garnet phosphor (YAG, yttrium aluminum garnet), the chemical formula is Y 3 A l5 o 12 , and with cerium (Ce, Cerium) as the host lattice (Host Lattice) and yttrium-aluminite leptite phosphor as the activator (Activator) component; wherein the atomic weight of cerium is 58, and the melting point is 795 ° C.

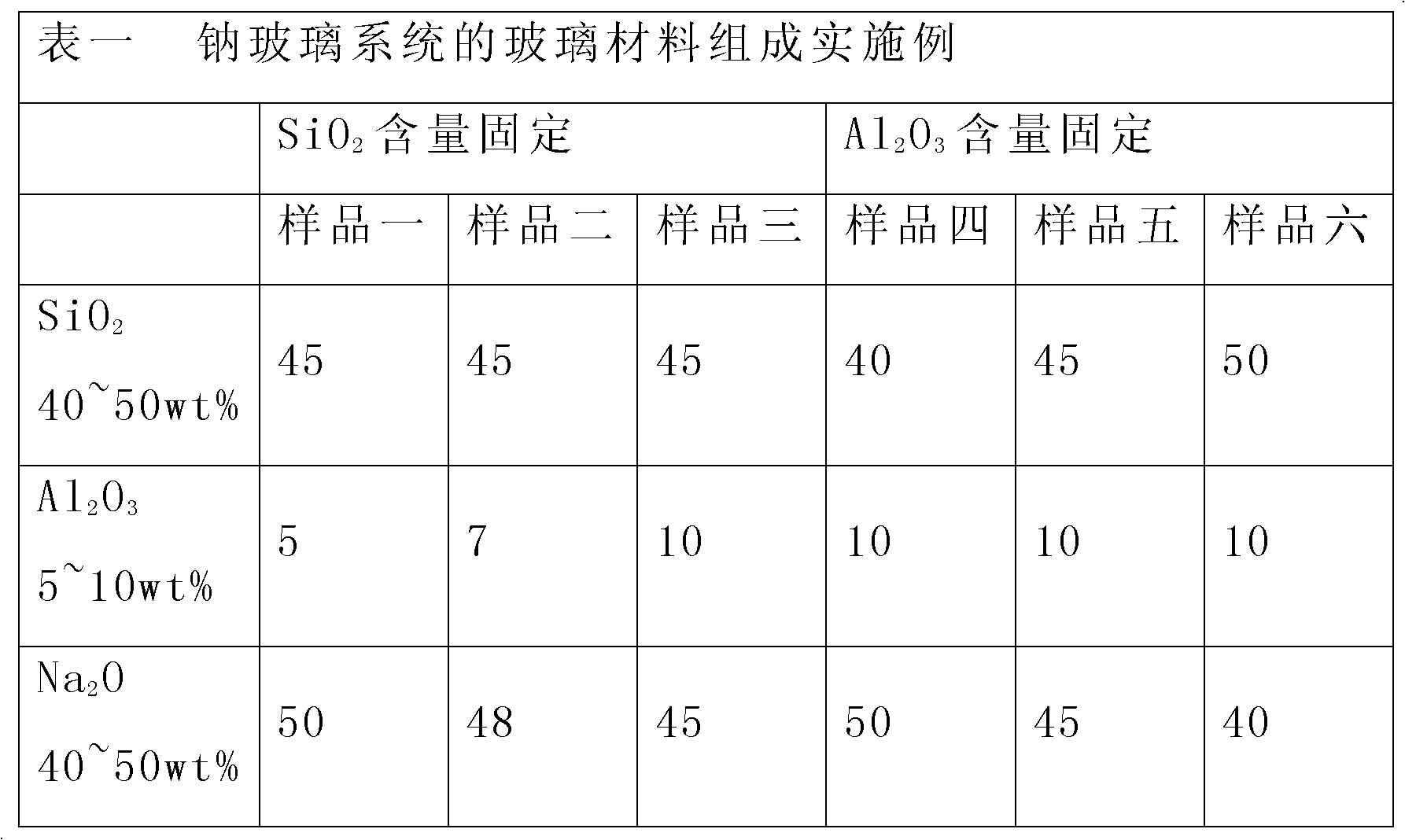

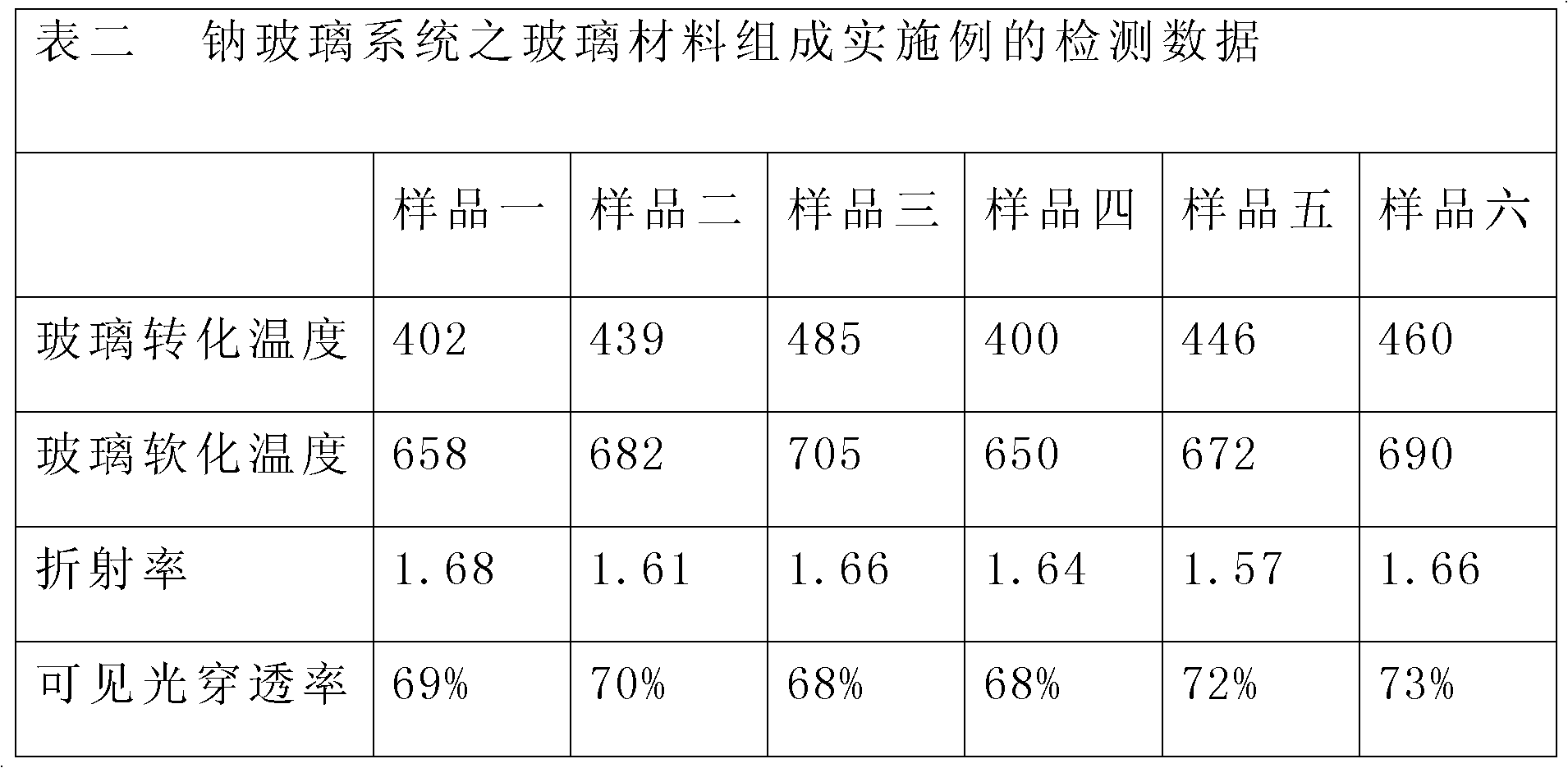

[0026] The low temperature glass material is made of silicon dioxide (SiO 2 ), alumina (Al 2 o 3 ), sodium oxide (Na 2 Sodium glass system low temperature glass material composed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com