Positive pole material of lithium ion battery and preparation method thereof

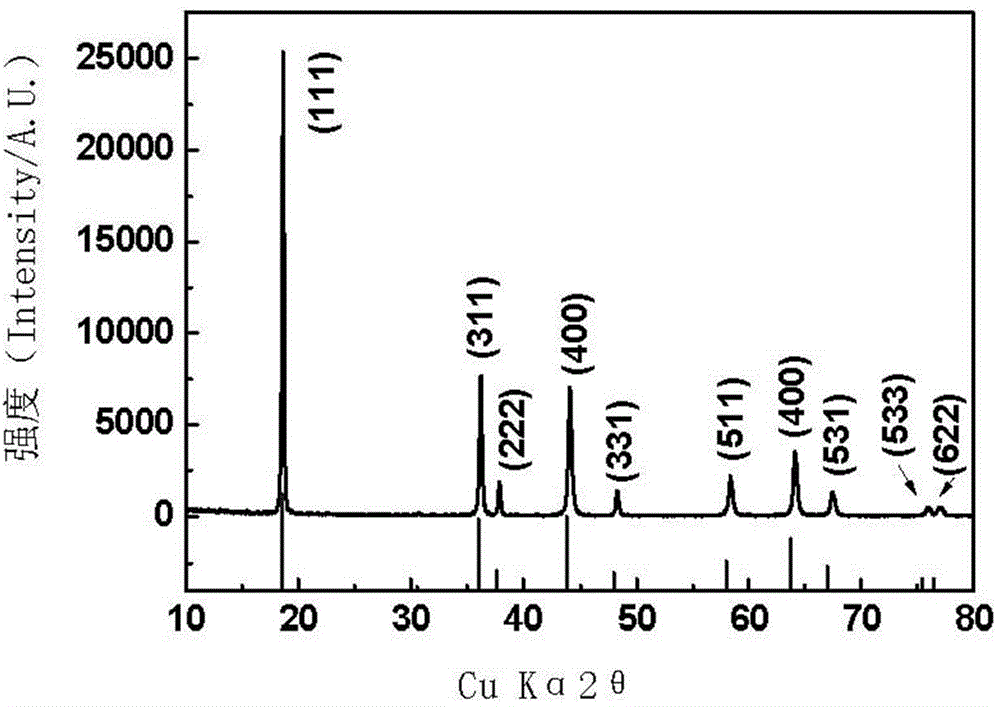

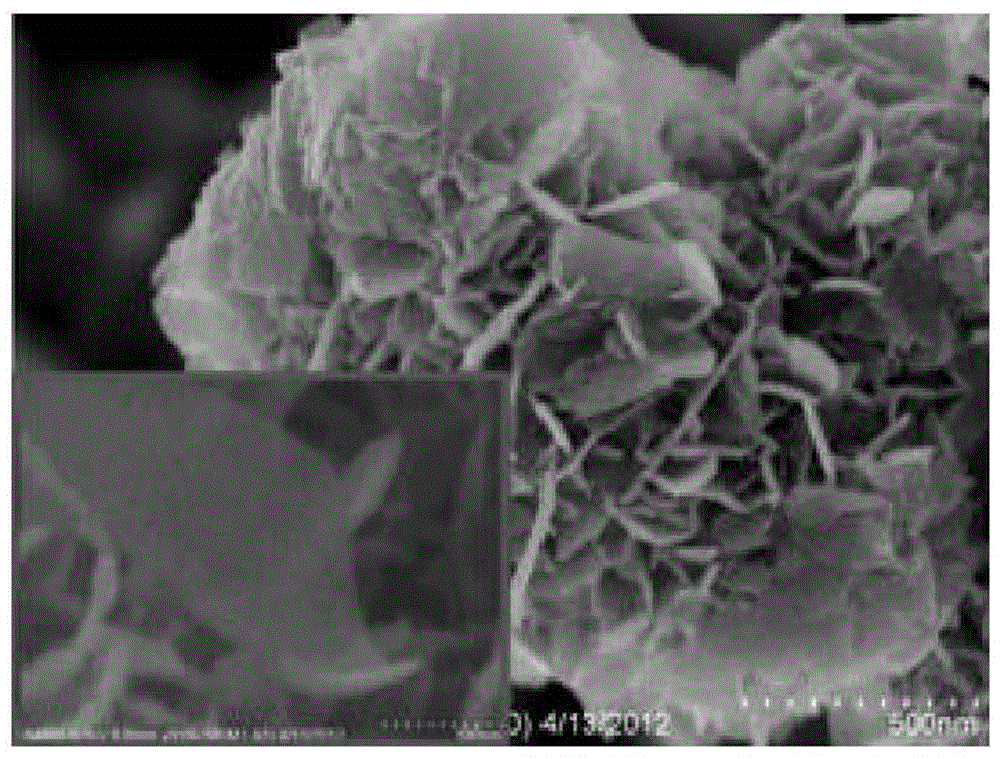

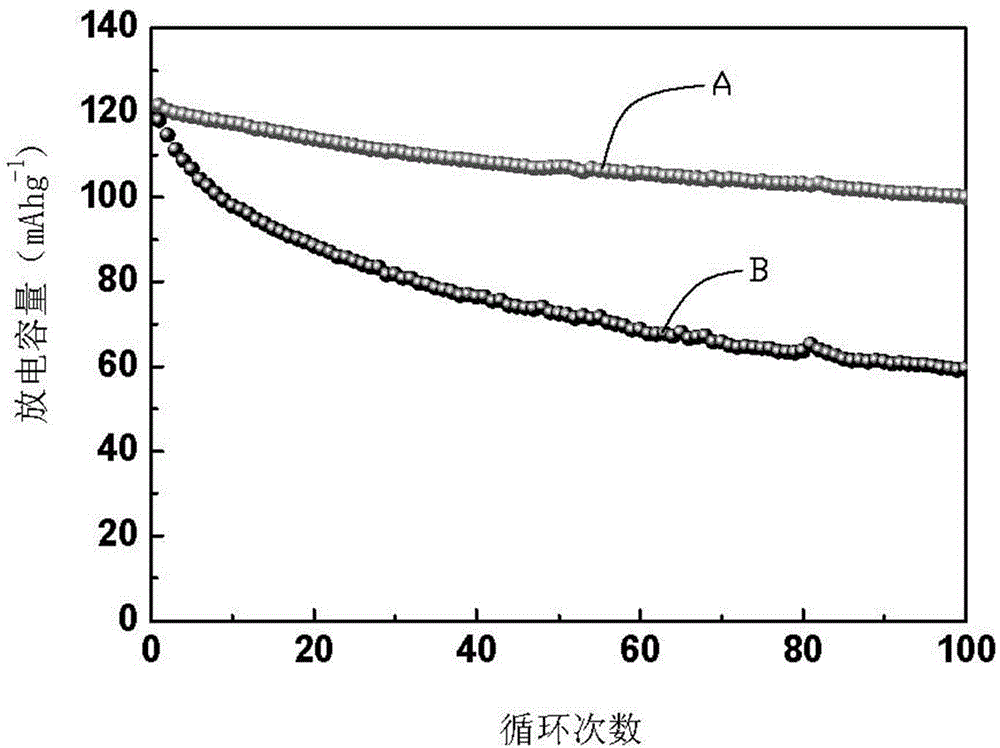

A lithium ion battery and cathode material technology, which is applied in the field of sheet nanostructured lithium ion battery cathode materials and their preparation, can solve the problems of restricting the development and application of lithium manganate, destroying lithium ion transport channels, affecting structural stability, and the like. Achieve the effect of low implementation cost, environmental friendliness and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] This technical solution provides a method for preparing a lithium ion battery cathode material, which includes the steps:

[0017] In the first step, according to the stoichiometric ratio, the high-valence manganese salt, the low-valence manganese salt and the oxidant are dissolved in deionized water and mixed uniformly to obtain a mixed solution.

[0018] In this step, the stoichiometric ratio is related to the specific materials of the high-valent manganese salt, low-valent manganese salt and oxidant used, that is, according to the various materials actually used, the high-valent manganese salt, low-valent manganese salt and the oxidant react to form The chemical reaction equation ratio of manganese dioxide is used to calculate the amount of high-valent manganese salt, low-valent manganese salt and oxidant. The high-valent manganese salt is permanganate or permanganate water and crystals. The permanganate can be specifically lithium permanganate, sodium permanganate, pota...

Embodiment 1

[0033] Dissolve 5.26 grams (g) of potassium permanganate, 0.56 g of manganese sulfate and appropriate amount of ammonium persulfate in 100 milliliters (mL) of deionized water and stir for 30 minutes (min); pour the resulting dark purple mixture into polytetrafluoroethylene The prepared hydrothermal tank is sealed with a stainless steel tube and placed in an explosion-proof oven; the parameters of the explosion-proof oven are set to 100 degrees Celsius (℃) for 48 hours (h); after the reaction is completed, the resulting slurry is filtered and washed with deionized water several times ; Put the product into an oven for drying, and control the drying temperature to 80 ℃ to obtain δ-MnO 2 Powder. Mix lithium hydroxide and manganese dioxide nanosheets in anhydrous acetone according to the stoichiometric ratio, and stir uniformly; dry the resulting mixture at room temperature to obtain powder; place the powder in a vacuum tube furnace Sintered at 400°C for 10 hours; the product is wa...

Embodiment 2

[0035] Dissolve 5.26 g of potassium permanganate, 0.56 g of manganese sulfate and appropriate amount of ammonium persulfate in 100 mL of deionized water and stir for 30 minutes; pour the resulting dark purple mixture into a hydrothermal tank made of polytetrafluoroethylene, using stainless steel After the tube is sealed, put it into an explosion-proof oven; set the parameters of the explosion-proof oven to 130 ℃ for 72 hours; after the reaction is completed, filter and wash the slurry with deionized water several times; put the product in an oven for drying, and control the drying temperature to 80 ℃, get δ-MnO 2 Powder. Mix lithium hydroxide and manganese dioxide nanosheets in anhydrous acetone according to the stoichiometric ratio, and stir uniformly; dry the resulting mixture at room temperature to obtain powder; place the powder in a vacuum tube furnace Sintered at 500°C for 15 hours; after the product is washed with deionized water, filtered and dried, the corresponding na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com