Slow/controlled-release microcapsule pesticide and preparation method thereof

A technology of microcapsules and pesticides, applied in the field of slow/controlled release microcapsule pesticides and its preparation, can solve problems such as the limitation of the application of microcapsule pesticides, the lack of controllability of the slow/controlled release performance of microcapsules, etc., and achieve good environmental stability performance, improved environmental stability, and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

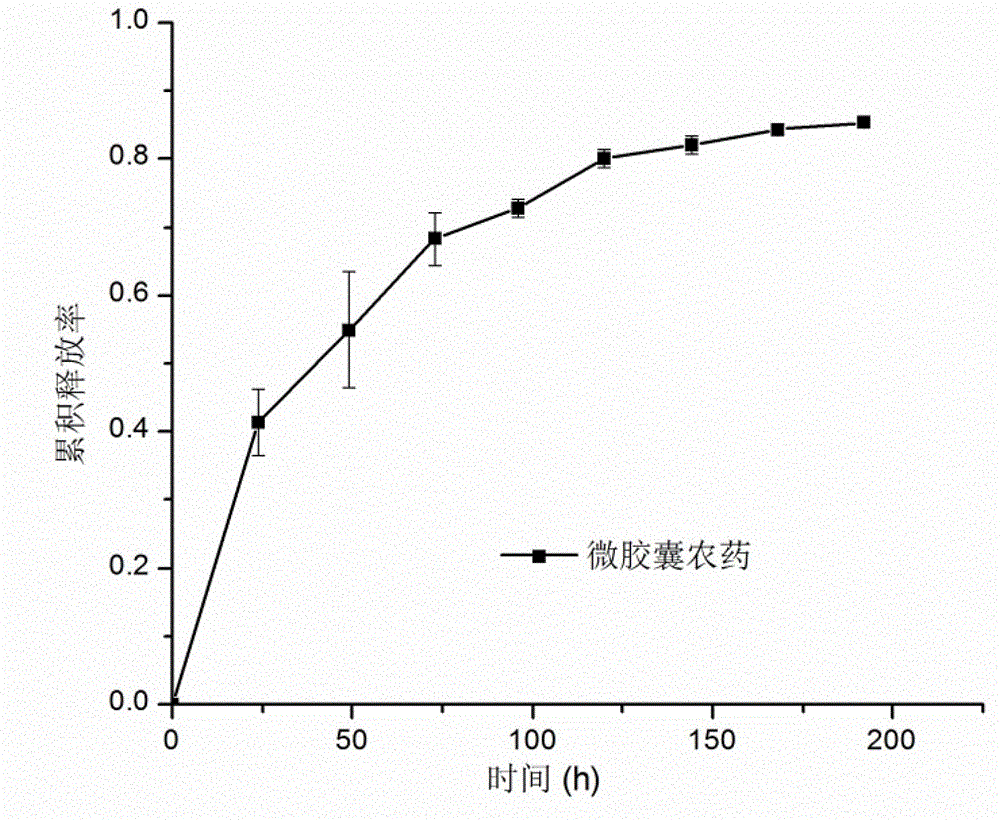

Examples

Embodiment 1

[0057] Embodiment 1, preparation slow / controlled release microcapsule pesticide

[0058] Dissolve 0.1g of OP-10 and 0.2g of SDS in 40g of water to form solution I. Add solution I into a 250mL four-necked flask, install a mechanical stirring device, a condenser, and a heating mantle, and raise the temperature to 60°C.

[0059] Dissolve 0.15g of OP-10 and 0.4g of SDS in 35g of water, and add it to a 500mL three-necked flask with a dropper, and install a mechanical stirring device. Dissolve 2 g of chlorpyrifos in 30 g of reaction monomer mixture (ethyl acrylate: styrene weight ratio 50:50) to form an oil phase, add it to the above-mentioned three-necked flask, stir at 1500 rpm for 10 min to form emulsion I.

[0060] 0.25 g of ammonium persulfate (APS) and 0.25 g of sodium bisulfite (SBC) were dissolved in 15 g of water as initiators.

[0061] Dissolve 0.5 g of ethylene glycol dimethacrylate in 3 g of reaction monomer mixture (ethyl acrylate: styrene by weight ratio 50:50) to for...

Embodiment 2

[0065] Embodiment 2, preparation slow / controlled release microcapsule pesticide

[0066] Dissolve 0.2g of OP-10 and 0.2g of LAS in 40g of water to form solution I. Add solution I into a 250mL four-necked flask, install a mechanical stirring device, a condenser, and a heating mantle, and raise the temperature to 60°C.

[0067] Dissolve 0.25g of OP-10 and 0.4g of LAS in 35g of water, and add it to a 500mL three-necked flask with a dropper, and install a mechanical stirring device. Dissolve 5g dimethoate in 30g reaction monomer mixture (methyl methacrylate: vinyl acetate: acrylic acid by weight ratio 45:47:8) to form an oil phase, add it to the above-mentioned three-necked flask, stir at 1500rpm for 10min to form an emulsion I.

[0068]0.3g of APS and 0.3g of SBC were dissolved in 15g of water as initiators.

[0069] Dissolve 1g of butanediol diacrylate in 6g of reaction monomer mixture (methyl methacrylate: vinyl acetate: acrylic acid: 45:47:8 by weight) to form coating soluti...

Embodiment 3

[0072] Embodiment 3, preparation slow / controlled release microcapsule pesticide

[0073] Dissolve 0.2g OP-10 and 0.2g LAS in 40g water to form solution I, add solution I into a 250mL four-necked flask, install a mechanical stirring device, a condenser tube, and a heating mantle, and raise the temperature to 60°C.

[0074] Dissolve 0.25g of OP-10 and 0.4g of LAS in 40g of water, and add it to a 500mL three-necked flask with a dropper, and install a mechanical stirring device. Dissolve 10g of malathion in 30g of reaction monomer mixture (methyl methacrylate: ethyl acrylate: hydroxyethyl acrylate: butyl methacrylate by weight ratio 45:45:7:3) to form an oil phase, Add it to the above-mentioned three-necked flask, and stir at 1500rpm for 10min to form emulsion I.

[0075] 0.3g APS and 0.3g SBC were dissolved in 20g water to form the initiator.

[0076] Dissolve 1 g of hexanediol dimethacrylate in 8 g of reactive monomer mixture (methyl methacrylate: ethyl acrylate: hydroxyethyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com