In-situ etching method for preparing hollow tin-based oxide/carbon composite nano-material

A nanomaterial and oxide technology, applied in the field of material synthesis and electrochemistry, can solve problems such as unfavorable environmental protection, cumbersome operation, time-consuming and labor-intensive, etc., and achieve the effects of energy saving, simple process and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A. Preparation of carbon-coated silica nanomaterials (references AntonioB.Fuertes, et al., Chem.Commun ., 2012, 48, 6124-6126.)

[0024] a. Measure 40ml of a mixture of ethanol (ethanol) and deionized water (the volume ratio of ethanol and water is 2:1), add 1.3ml of ammonia water (NH 3 ·H 2 O), mix evenly, and stir at 30°C for 0.5h; measure 1.4ml tetraethyl orthosilicate (TEOS) and add it to the above solution, after mixing, weigh 0.2g resorcinol with an electronic balance, completely After dissolving, add 0.3ml formaldehyde solution (37wt%) and continue the reaction for 24h;

[0025] b. Put the above mixed solution into a 100ml autoclave lined with polytetrafluoroethylene, and react at 110°C for 24h; Drying and other steps can obtain the template required for the preparation of the present invention—carbon-coated silicon dioxide nanometer material.

[0026] B. Preparation of tin-based oxide / carbon composite nanomaterials

[0027] a. Use an electronic balance to w...

Embodiment 2

[0033] The preparation process and steps of this embodiment are exactly the same as in Example 1, except that in the B(c) step:

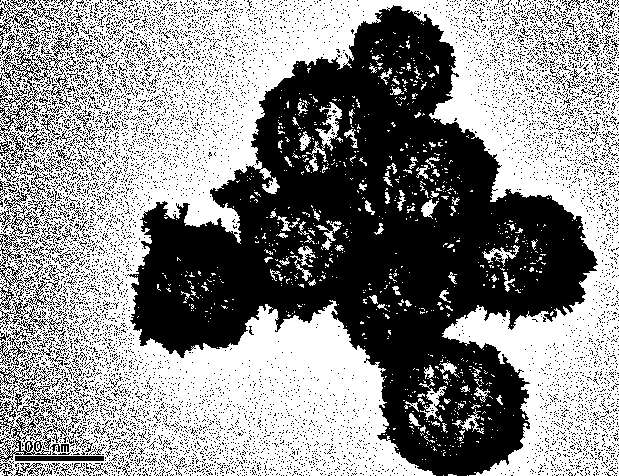

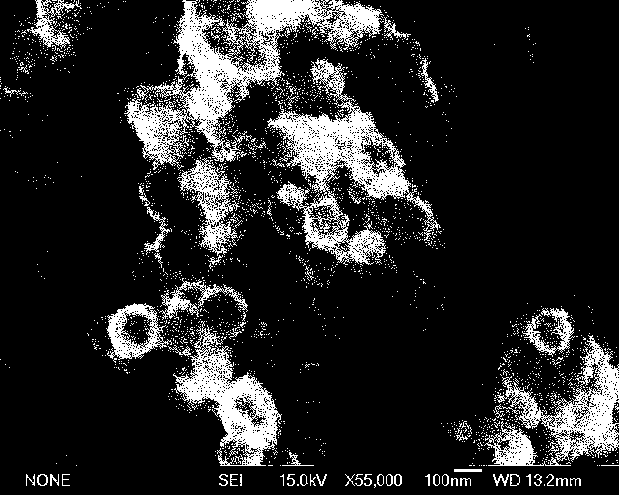

[0034] The above materials are heat-treated at 600° C. in an air atmosphere to obtain the hollow tin-based oxide / carbon composite nanomaterial as the final product prepared in the present invention.

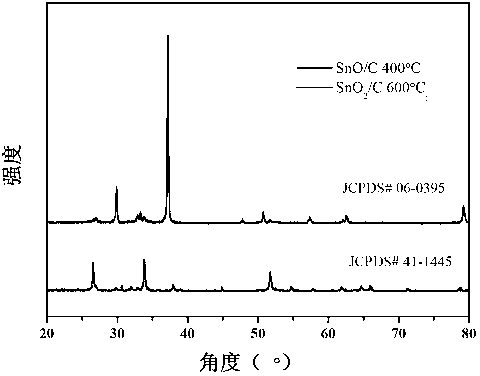

[0035] The obtained result is basically similar in appearance to Example 1, but the crystal phase is completely different. The product obtained in this example is a pure-phase tin dioxide / carbon composite nanomaterial.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com