Dielectric layer for embedded capacitance material, embedded capacitance material, preparation method and use of embedded capacitance material

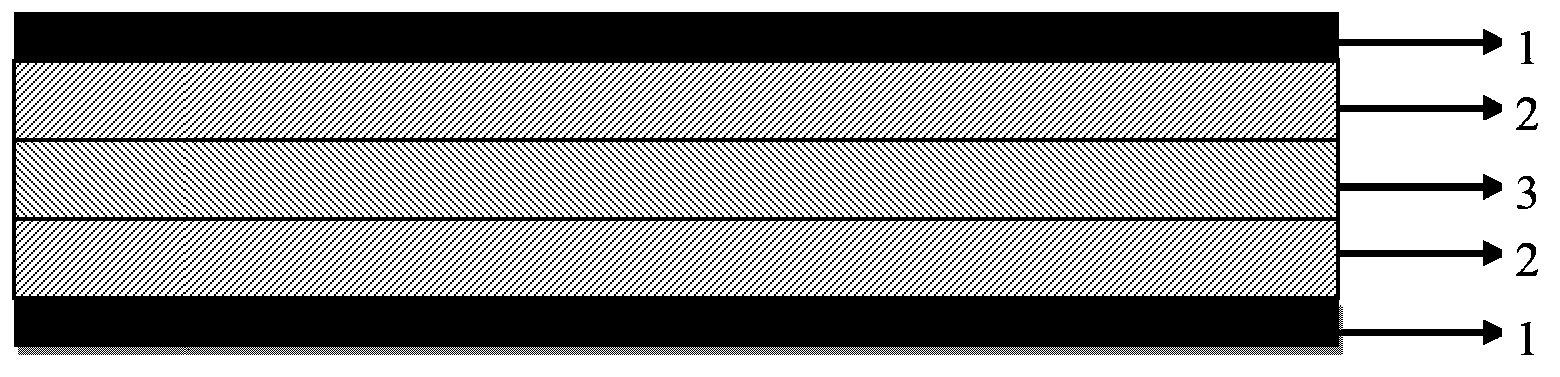

A technology of dielectric layer and thin film layer, which is applied in the direction of circuit substrate materials, chemical instruments and methods, lamination, etc., can solve the problem of not being able to further increase the dielectric constant of buried capacitance materials, and the brittleness of buried capacitance materials ( Intensity, low dielectric constant of embedding materials and other issues, to achieve the effect of preventing leakage current, excellent strength and impact resistance, and improving the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

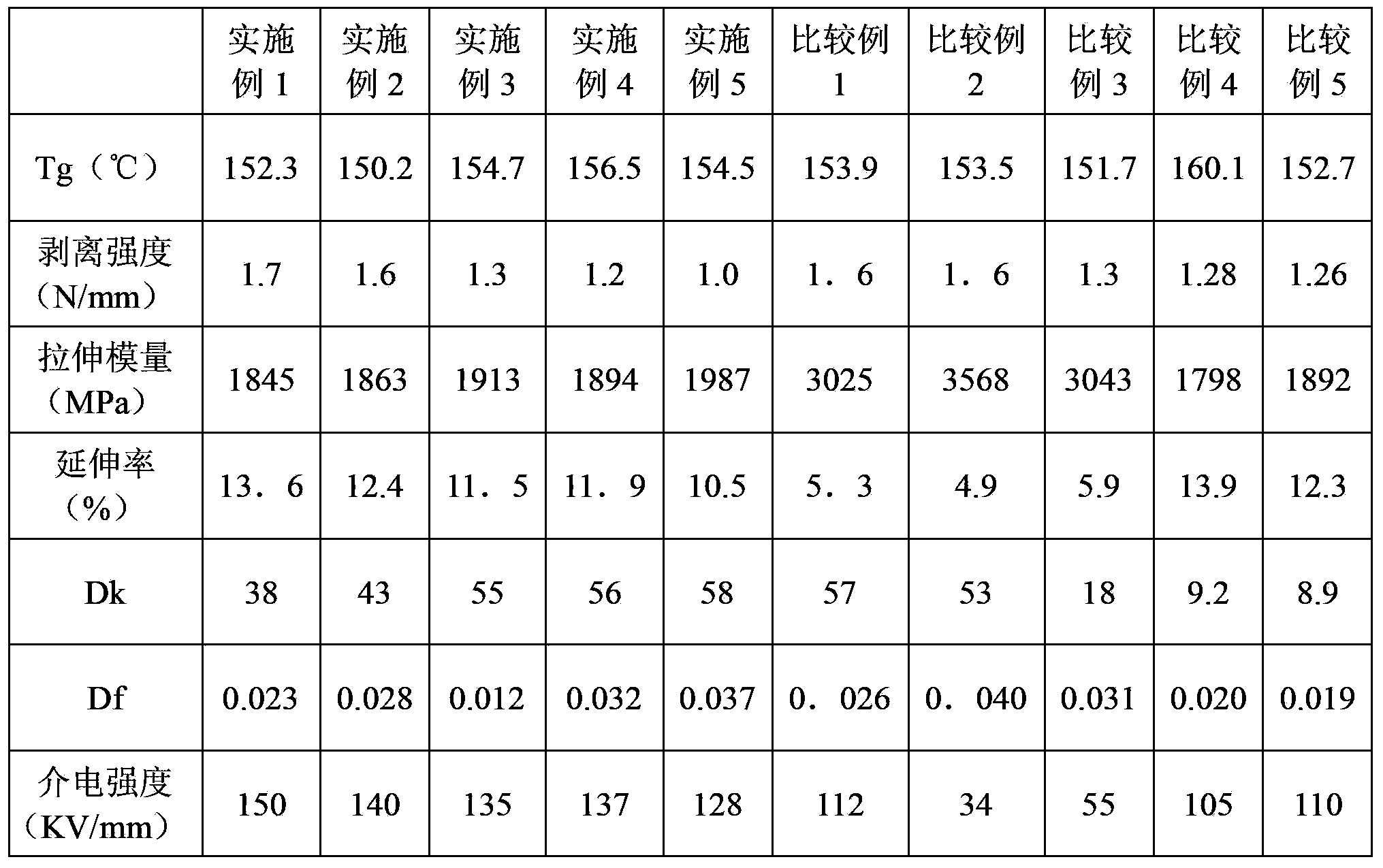

Examples

Embodiment 1

[0047] Dissolve 35g of bisphenol A type epoxy resin (epoxy resin A), 45g of brominated epoxy resin (epoxy resin B) and 20g of carboxy-terminated nitrile rubber (C) in ethylene glycol methyl ether, and add O-cresol novolac resin and 2-MI (2-methylimidazole) in a molar ratio of 0.9 to epoxy resin were mixed at room temperature to obtain a glue solution. The obtained glue solution was coated on the copper foil, and then baked in an oven at 155° C. for 5 minutes to be cured into stage B to obtain a resin-coated copper foil (RCC). The thickness of the RCC glue layer was 8 μm.

[0048] Dissolve 130g bisphenol A type epoxy resin (epoxy resin A), 70g brominated epoxy resin (epoxy resin B) and 500g carboxy-terminated nitrile rubber (C) in ethylene glycol methyl ether, then add Relative to the o-cresol novolac resin and 2-MI (2-methylimidazole) with a molar ratio of 0.9 to the epoxy resin, 300g of copper powder coated with barium titanate ceramic filler is added, and the particle size o...

Embodiment 2

[0051] 45g bisphenol A epoxy resin, 55g brominated epoxy resin and 20g phenoxy resin are dissolved in ethylene glycol methyl ether, and add o-cresol novolac resin and 2 -MI (2-methylimidazole), and then add 90.5g of barium titanate with a median particle size of 10nm, and its volume percentage is 15%, and then mix at room temperature to obtain a glue solution. The obtained glue solution was coated on the copper foil, and then baked in an oven at 155° C. for 5 minutes to be cured into stage B to obtain a resin-coated copper foil (RCC). The thickness of the RCC glue layer was 13 μm.

[0052] Dissolve 250g of polyimide resin and 150g of hydroxyl-terminated nitrile rubber in ethylene glycol methyl ether, then add 125g of bisphenol A epoxy resin and 75g of BT resin, and then add silver powder coated with barium titanate ceramic filler 400g, the median particle diameter of silver powder is 100nm, then mixed at room temperature to obtain glue. The obtained glue solution was coated o...

Embodiment 3

[0055] Dissolve 45g bisphenol A type cyanate resin (resin A), 55g brominated epoxy resin (epoxy resin B) and 20g carboxy-terminated nitrile rubber (C) in ethylene glycol methyl ether, and add 2 -MI (2-methylimidazole), and then add 342g of barium titanate with a median particle size of 100nm, the volume fraction of which is 40%, and mix at room temperature to obtain a glue solution. The obtained glue solution was coated on the copper foil, and then baked in an oven at 155° C. for 5 minutes to be cured to stage B to obtain a resin-coated copper foil (RCC). The thickness of the RCC glue layer was 25 μm.

[0056] Dissolve 95g bisphenol A type cyanate resin (resin A), 55g brominated epoxy resin (epoxy resin B) and 400g carboxy-terminated nitrile rubber (C) in ethylene glycol methyl ether, then add 2 -MI (2-methylimidazole), then add 450g of nickel powder coated with barium titanate ceramic filler, the median particle size of the nickel powder is 300nm, and then mix at room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com