Biochemical treatment process for ethylene waste lye

A technology for ethylene waste lye and biochemical treatment, applied in chemical instruments and methods, natural water treatment, water/sewage multi-stage treatment, etc., can solve problems such as instability, poor effluent quality, impact damage, etc. The effect of strong impact, low treatment cost and stable effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the preparation of bacterial classification

[0021] The bacterial strain Thiomonas intermedia BCRC17547 involved in the present invention was purchased from the Biological Resource Preservation and Research Center of the Institute of Food Industry Development, Taiwan Province of China. After purchasing, operate according to the product instructions provided by the supplier. The liquid medium components used are: yeast powder 5g / L, disodium hydrogen phosphate 4.5g / L, potassium dihydrogen phosphate 1.5g / L, magnesium sulfate heptahydrate 0.1g / L, ammonium chloride 0.3g / L, sodium thiosulfate pentahydrate 5g / L. Adjust the pH of the medium to 6.0. Operate according to conventional microbiological methods, culture on a shaker at 30°C after inoculation, and harvest strains within 48 hours.

[0022] The strain Pseudomonas sp.XQ3m-2 involved in the present invention was obtained by screening, separating and purifying from nature by the inventor, and was preserved ...

Embodiment 2

[0024] Embodiment 2: the preparation of flora in the activated sludge reaction system and the film-hanging of biological aerated filter

[0025] The mature culture liquid of Thiomonas intermedia BCRC17547 harvested in Example 1 is mixed with municipal activated sludge in a volume ratio of 1:4 to obtain the aeration reaction tank (1# reaction tank) used in the first activated sludge system. flora.

[0026] The Pseudomonas sp.XQ3m-2CCTCC M2010162 mature culture bacterium liquid obtained by harvesting in Example 1 is mixed with municipal activated sludge in a volume ratio of 1: 4 to obtain aeration reaction tank (2# reaction) for the second activated sludge system Bacteria in the pond).

[0027] The mature culture of Pseudomonas sp.XQ3e CCTCC M209182 harvested in Example 1 was mixed with municipal activated sludge at a volume ratio of 1:4 to obtain the flora used in the biological aerated filter (3# reaction tank), Then hang the film according to the usual method. The typical ...

Embodiment 3

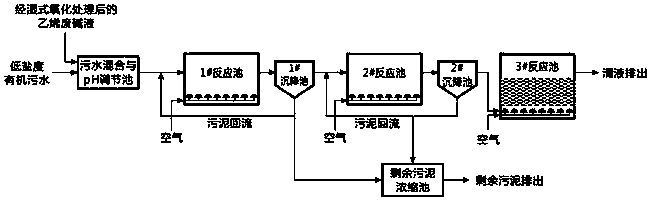

[0028] Embodiment 3: process ethylene waste lye

[0029] Mix the ethylene waste lye after wet oxidation treatment with local domestic sewage at a volume ratio of 1:6, stir evenly, and adjust the pH to 6.5. Influent COD measured Cr It is 1520mg / L. The mixed sewage is pumped into the reaction system of the present invention with a peristaltic pump. In the first activated sludge plant, the hydraulic retention time is 20.0h, the reflux ratio is 1, the water temperature is 30.0°C, the settling time of 1# settling tank is 4.1h, and the effluent COD of 1# settling tank Cr It is 182mg / L. In the second activated sludge plant, the hydraulic retention time is 20.0h, the reflux ratio is 1, the water temperature is 30.0°C, the settling time in the 2# settling tank is 4.1h, and the effluent COD of the 2# settling tank Cr It is 105mg / L. The effluent of 2# sedimentation tank enters the biological aerated filter device, the hydraulic retention time is 2.0h, the water temperature is 14.0℃,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com