Fluorine-containing light-cured waterborne coating and preparation method thereof

A water-based coating, light-curing technology, applied in the coating field, can solve the problems of low production efficiency, application limitations, poor stain resistance of exterior wall coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

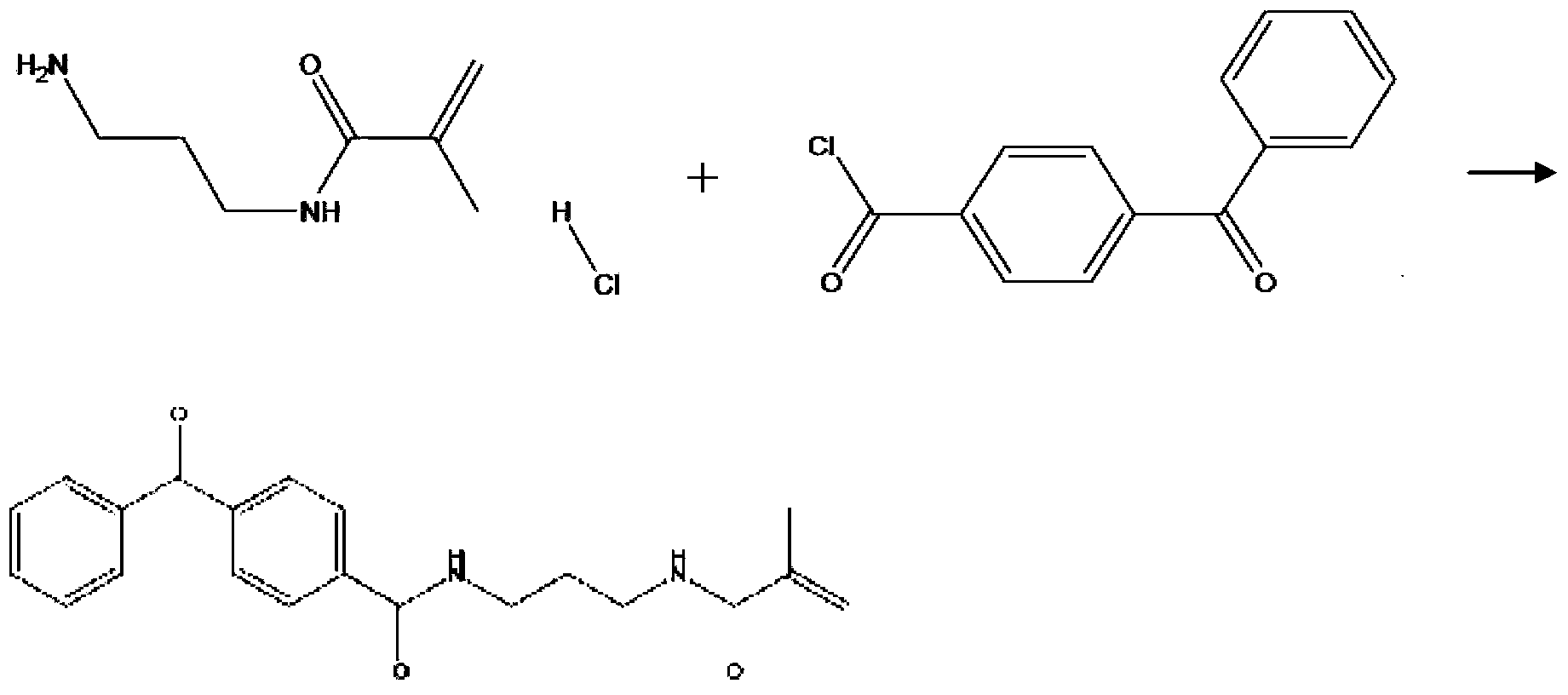

[0055] Embodiment 1: Synthesis of photoactive fluorine-containing (trifluoroethyl methacrylate) hydrophilic resin

[0056] Weigh 5.55 g (50 mmol) of vinylpyrrolidone and 0.5 g (2.9 mmol) of trifluoroethyl methacrylate into a three-necked flask, then add N-[3-(4- Benzoylbenzamido) propyl] methacrylamide 0.18g (0.52mmol), put nitrogen into the flask to remove the air, then add azobisisobutyronitrile 0.1g (0.6mmol), the liquid surface After being filled with nitrogen, the container was closed and heated at 55°C for 12 hours. After the reaction, the solution was precipitated with ether, and the precipitate was filtered out and dried in an oven to obtain 5 g of a white solid. The detected photoactive group benzophenones is 0.1 mmol / g.

Embodiment 2

[0057] Embodiment 2: Synthesis of photoactive fluorine-containing (tetrafluoropropyl methacrylate) hydrophilic resin

[0058] Weigh 5.55 g (50 mmol) of vinylpyrrolidone and 0.5 g (2.5 mmol) of tetrafluoropropyl methacrylate into a three-necked flask, then add N-[3-(4- Benzoylbenzamido) propyl] methacrylamide 0.18g (0.52mmol), put nitrogen into the flask to remove the air, add 0.1g (0.6mmol) of azobisisobutyronitrile, the liquid surface is full Close the container after nitrogen gas, and heat at 70°C for 30 hours. After the reaction, the solution was precipitated with ether, and the precipitate was filtered out and dried in an oven to obtain 5 g of a white solid. The detected photoactive group benzophenones is 0.1 mmol / g.

Embodiment 3

[0059] Embodiment 3: Synthesis of photoactive fluorine-containing (hexafluorobutyl methacrylate) hydrophilic resin

[0060] Weigh 5.55g (50mmol) of vinylpyrrolidone and 0.5g (2mmol) of hexafluorobutyl methacrylate into a three-necked flask, then add N-[3-(4-benzene Formyl benzamido) propyl] methacrylamide 0.18g (0.52mmol), pass nitrogen into the flask to remove the air, then add azobisisobutyronitrile 0.1g (0.6mmol), the liquid surface is full The container was closed after nitrogen, and heated at 50°C for 48 hours. After the reaction, the solution was precipitated with ether, and the precipitate was filtered out and dried in an oven to obtain 5 g of a white solid. The detected photoactive group benzophenones is 1 mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com