Attapulgite material with anti-bacterial function and preparation method thereof

A technology of attapulgite and attapulgite powder, which is applied in botany equipment and methods, fungicides, chemicals for biological control, etc., and can solve problems such as heavy metal pollution, high cost, and complicated compounding process of heavy metals and materials , to achieve the effect of enhanced antibacterial power, low production cost, and large industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] S1. For granulation, put attapulgite pellets with a prefabricated core of 3 mm into the granulator, spray 10 kg of blank water solution—add 6 kg of attapulgite powder—start the equipment and stir for 20 minutes—spray 10 kg of blank water solution repeatedly Add 6kg of attapulgite and continue to stir for 20 minutes—increase the amount of water agent to 24kg, add 10kg of attapulgite powder—become a ball of 3mm, stop adding water—continue to round for 30 minutes—add 10kg of attapulgite—continue to round to obtain Semi-finished products. The whole production process takes 2.5 hours;

[0035] S2. Drying at 80°C for 24 hours until the moisture is less than 2% of the total mass fraction to obtain the final product.

[0036] The antibacterial rates of the finished product to Escherichia coli and Candida albicans are 10% and 15% respectively.

Embodiment 2

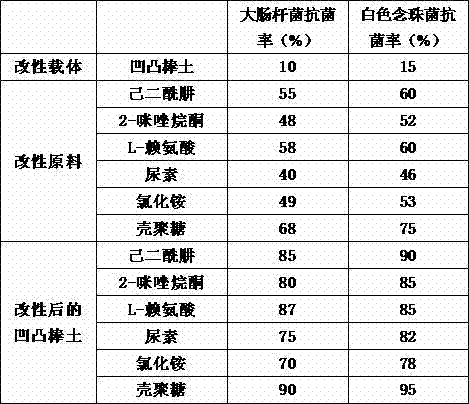

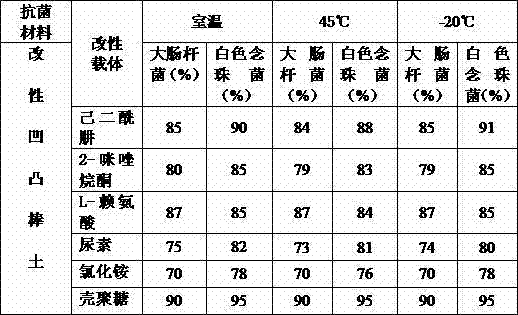

[0038] The antibacterial effects of adipic hydrazide, 2-imidazolidinone, L-lysine, urea, ammonium chloride and chitosan were determined by agar diffusion disc method.

[0039] The experimental results prove that the antibacterial effects of adipic hydrazide, 2-imidazolidinone, L-lysine, urea, ammonium chloride and chitosan on Escherichia coli and Candida albicans under the same dosage conditions are as follows: 55% and 60%, 48% and 52%, 58% and 60%, 40% and 46%, 49% and 53%, 68% and 75%.

Embodiment 3

[0041] S1. Preparation of functional water agent, weigh 4kg of adipic hydrazide, dissolve in 40kg of water, stir to dissolve evenly. It is prepared into a functional water agent with a mass concentration of 10%;

[0042] S2. Granulating, put attapulgite pellets with a prefabricated inner core of 3 mm into the granulator, spray 10 kg of functional water agent in S1—add 6 kg of attapulgite powder—start the equipment and stir for 20 minutes—spray 10 kg repeatedly Add 6kg of attapulgite to functional water and continue to stir for 20 minutes—increase the amount of functional water to 24kg, add 10kg of attapulgite powder—to form a ball of 3mm, stop adding functional water—continue to roll for 30 minutes—add 10kg of attapulgite Stick clay - continue to roll to get a semi-finished product. The whole production process takes 2.5 hours, and the mass ratio of modified raw materials to attapulgite powder is 1:8;

[0043] S3. Drying at 80°C for 24 hours until the moisture is less than 2% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com