Roxburgh rose buccal tablets and preparation method thereof

A technology of buccal tablets and Rosa roxburghii, which is applied in the field of Rosa roxburghii buccal tablets and its preparation, can solve the problems of low utilization rate of equipment, short harvest period, high cellulose content, etc., to save a lot of cost, easy to digest and absorb, The effect of simple storage conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

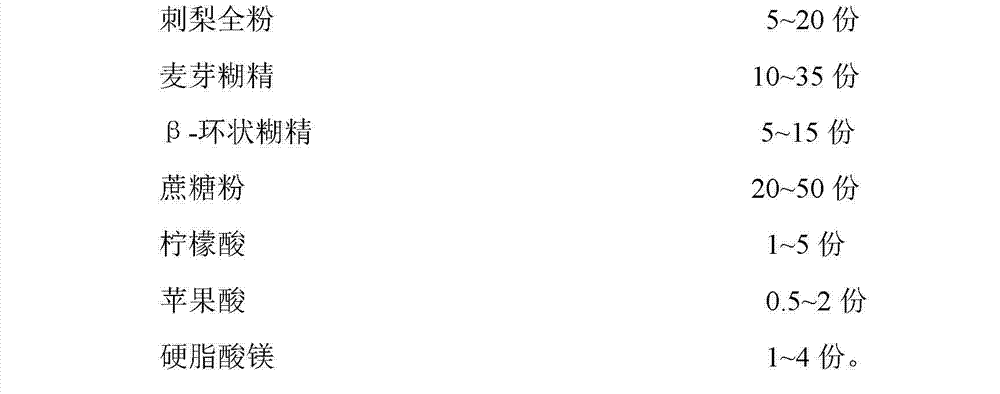

Method used

Image

Examples

Embodiment 1

[0036] (1) Screen the Rosa roxburghii fruit, wash and dry the surface moisture, then dry it at 40°C to a water content of 15%, and then crush it to a particle size of 200 mesh to obtain Rosa roxburghii powder, and add sucrose, malic acid and citric acid Grinding to 200 mesh;

[0037] (2) Stir and mix 5 parts of Rosa roxburghii whole powder, 30 parts of maltodextrin, 15 parts of β-cyclodextrin, 25 parts of sucrose powder, 2 parts of citric acid and 1 part of malic acid, and then spray the volume percentage concentration Make soft material for 40% ethanol solution, make the content of ethanol solution in the soft material be 8%;

[0038] (3) Let the soft material pass through a 20-mesh sieve to form granules, and then dry at 50°C until the moisture content is 5%;

[0039] (4) Pass the dried soft material granules through a 20-mesh sieve for granulation. After granulation, add 2 parts of magnesium stearate and mix evenly. Cover and let stand for 8 minutes, then compress into tab...

Embodiment 2

[0041] (1) Screen the Rosa roxburghii fruit, wash and dry the surface moisture, then dry it at 60°C to a water content of 5%, and then crush it to a particle size of 100 mesh to obtain Rosa roxburghii powder, and add sucrose, malic acid and citric acid Grinding to 100 mesh;

[0042] (2) Stir and mix 10 parts of thorn pear whole powder, 35 parts of maltodextrin, 5 parts of β-cyclodextrin, 20 parts of sucrose powder, 1 part of citric acid and 2 parts of malic acid, and then spray the volume percentage concentration Make soft material for 70% ethanol solution, make the content of ethanol solution in the soft material be 12%;

[0043] (3) Let the soft material pass through a 10-mesh screen to form granules, and then dry at 40°C to a moisture content of 6%;

[0044] (4) Pass the dried soft material granules through a 10-mesh sieve for granulation. After granulation, add 1 part of magnesium stearate and mix evenly. Cover and let stand for 5 minutes, then compress into tablets, steril...

Embodiment 3

[0046] (1) Screen the Rosa roxburghii fruit, wash and dry the surface moisture, then dry it at 70°C to a water content of 10%, and then crush it to a particle size of 400 mesh to obtain Rosa roxburghii powder, and add sucrose, malic acid and citric acid Grinding to 400 mesh;

[0047] (2) Stir and mix 15 parts of thorn pear whole powder, 15 parts of maltodextrin, 10 parts of β-cyclodextrin, 40 parts of sucrose powder, 4 parts of citric acid and 1.5 parts of malic acid, and then spray the volume percentage concentration Make soft material for 50% ethanol solution, make the content of ethanol solution in the soft material be 5%;

[0048] (3) Let the soft material pass through a 30-mesh sieve to form granules, and then dry at 80°C to a moisture content of 1%;

[0049] (4) Pass the dried soft material granules through a 30-mesh sieve for granulation. After granulation, add 4 parts of magnesium stearate and mix evenly. Cover and let stand for 15 minutes, then compress into tablets,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com