Silanized functionalized ionic liquid/hydrotalcite-like compound composite material, and preparation method and application thereof

A technology of ionic liquid and composite material, applied in the field of silanized ionic liquid/hydrotalcite-like composite material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

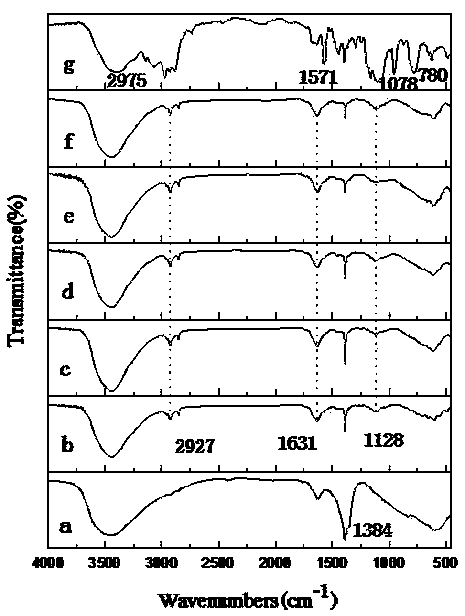

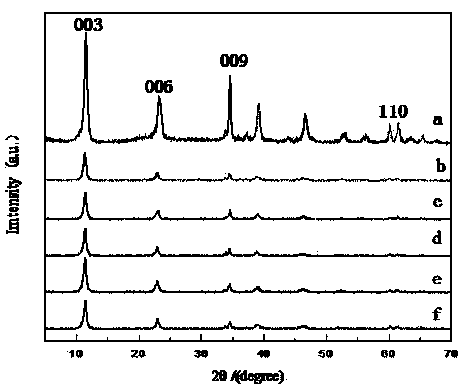

Image

Examples

Embodiment 1

[0038] (a) Preparation of silane functionalized ionic liquid 1-methyl-3-(triethoxysilylpropyl) imidazole hydrochloride

[0039] Pipette 20 mL of N-methylimidazole (10.3 g, 0.25 mol) into a round-bottom flask, and add 59.6 mL (60.20 g, 0.25 mol) of equimolar 3-chloropropyltriethoxysilane to the flask under constant stirring. The mixture was added to the same volume of absolute ethanol (20 mL) as N-methylimidazole, and the reaction solution was refluxed and stirred at 80°C for 96 hours. During the reaction, it was protected by nitrogen. After the reaction, the solvent and unreacted volatile substances were removed by rotary evaporation, dissolved in a small amount of chloroform, and then subjected to silica gel column chromatography. The components were collected to remove the solvent and dried under vacuum at 40°C for 24 hours to constant weight to obtain a light yellow transparent liquid 1-formaldehyde 3-(triethoxysilylpropyl) imidazole hydrochloride;

[0040] (b) Preparation of h...

Embodiment 2

[0045] (a) Preparation of silane functionalized ionic liquid 1-methyl-3-(triethoxysilylpropyl) imidazole hydrochloride

[0046] Synthesize using the method and conditions of step (a) in Example 1;

[0047] (b) Preparation of hydrotalcite-like

[0048] The divalent metal salt Zn(NO 3 ) 2 And trivalent metal salt Al(NO 3 ) 3 Prepare a mixed salt solution at a molar ratio of 2:1, with a total metal ion concentration of 0.6 mol / L. Titrate the above mixed solution and sodium hydroxide solution with a molar concentration of 2 mol / L at the same time, and control the pH between 9.0 and 10.0 , Stirring vigorously, aging at 80°C for 8 hours. The obtained slurry was filtered by suction, the filter cake was washed 4 times with distilled water, and dried at 60°C for 24 hours to resemble hydrotalcite;

[0049] (c) Preparation of silanized ionic liquid / hydrotalcite-like composite materials

[0050] Weigh 0.8 g of silane functionalized ionic liquid and 1.6 g of hydrotalcite (mass ratio 1:2) into a r...

Embodiment 3

[0052] (a) Preparation of silane functionalized ionic liquid 1-methyl-3-(triethoxysilylpropyl) imidazole hydrochloride

[0053] Synthesize using the method and conditions of step (a) in Example 1;

[0054] (b) Preparation of hydrotalcite-like

[0055] The divalent metal salt Zn(NO 3 ) 2 And trivalent metal salt Al(NO 3 ) 3 Prepare a mixed salt solution at a molar ratio of 2:1, with a total metal ion concentration of 0.6 mol / L. Titrate the above mixed solution and sodium hydroxide solution with a molar concentration of 2 mol / L at the same time, and control the pH between 9.0 and 10.0 , Stirring vigorously, aging at 50°C for 18 hours. The obtained slurry was filtered with suction, the filter cake was washed 5 times with distilled water, and dried at 60°C for 24 hours to resemble hydrotalcite;

[0056] (c) Preparation of silanized ionic liquid / hydrotalcite-like composite materials

[0057] Weigh 0.8 g of silane functionalized ionic liquid and 0.8 g of hydrotalcite (mass ratio 1:1) into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com