Novel transparent glitter ceramic with garnet structure and preparation method thereof

A transparent ceramic and garnet technology, applied in the field of scintillation ceramic material system and its preparation, can solve the problems of difficult preparation, high cost of material preparation, and reduced luminous efficiency, etc., and achieve the effect of easy industrial production, high optical performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] In a preferred embodiment of the present invention, the preparation method of the scintillation transparent ceramic system with garnet structure includes the steps of batching, drying, burning, molding, sintering, annealing, etc.:

[0070] 1) Ingredients: Commercially available raw materials with a purity of more than 99.99% or below the micron level are used, and there is no need to reprocess the raw materials, which can save costs and facilitate industrialization. Precise batching is carried out according to the above structural formula, and uniform mixing is carried out on a high-energy planetary ball mill. The medium used includes but is not limited to deionized water, absolute ethanol, acetone, glycerin or a combination thereof. The ball mill tank and balls used are PTFE products, such burning can remove organic impurities (PTFE, etc.) and effectively avoid the doping of impurity ions. In order to improve the efficiency of ball milling, we design the ball diameter ...

Embodiment 1

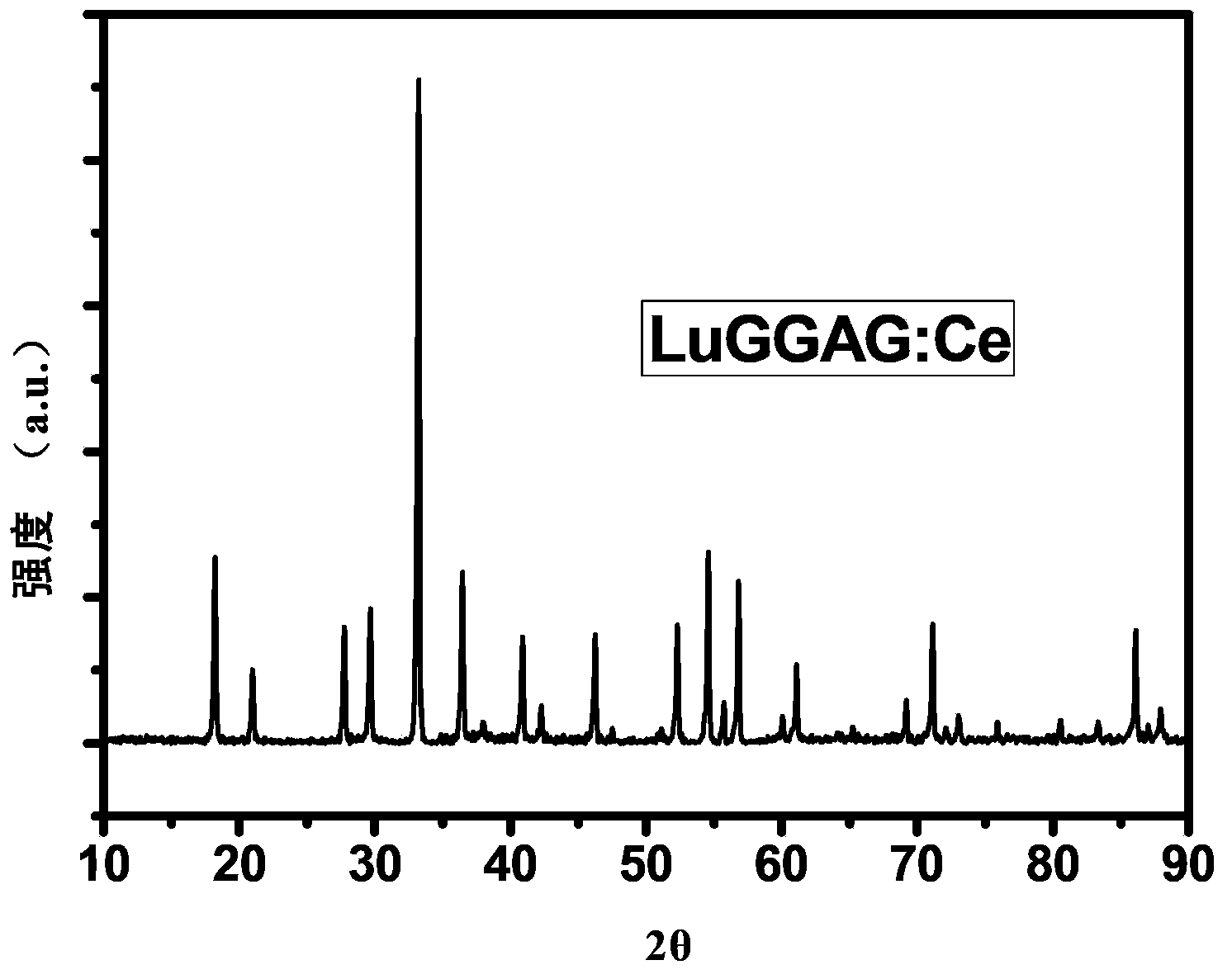

[0086] Example 1: (x=0.005, y=0.1, z=0.6, m=3), Re is Ce, A is Gd, C is Ga, namely Ce 0.005 (Lu 0.1 Gd 0.9 ) 2.995 (Al 0.6 Ga 0.4 ) 5 o 12

[0087] Commercially available high-purity (99.99%) Lu 2 o 3 (2μm), Gd 2 o 3 (2μm), Al 2 o 3 (0.2μm), Ga 2 o 3 (2μm), CeO 2 (50nm) as the starting material, accurately weigh the mass of each oxide according to the above formula, use absolute ethanol as the ball milling medium, and use polytetrafluoroethylene balls as the grinding balls, according to the mass ratio ball: material: absolute ethanol ≈ 6: 1:1.2, mixing materials by high-energy planetary ball mill, ball milling speed 300r / min, ball milling time 12h, the obtained slurry is dried in a blast drying oven at 60°C for 12h, and the obtained powder is treated above 600°C for 2-4 hours, Grind in an alumina crucible, pass through a 200-mesh sieve to obtain the required powder, and then press it into a disc with a diameter of 50mm in a steel mold and use cold isostatic pre...

Embodiment 2

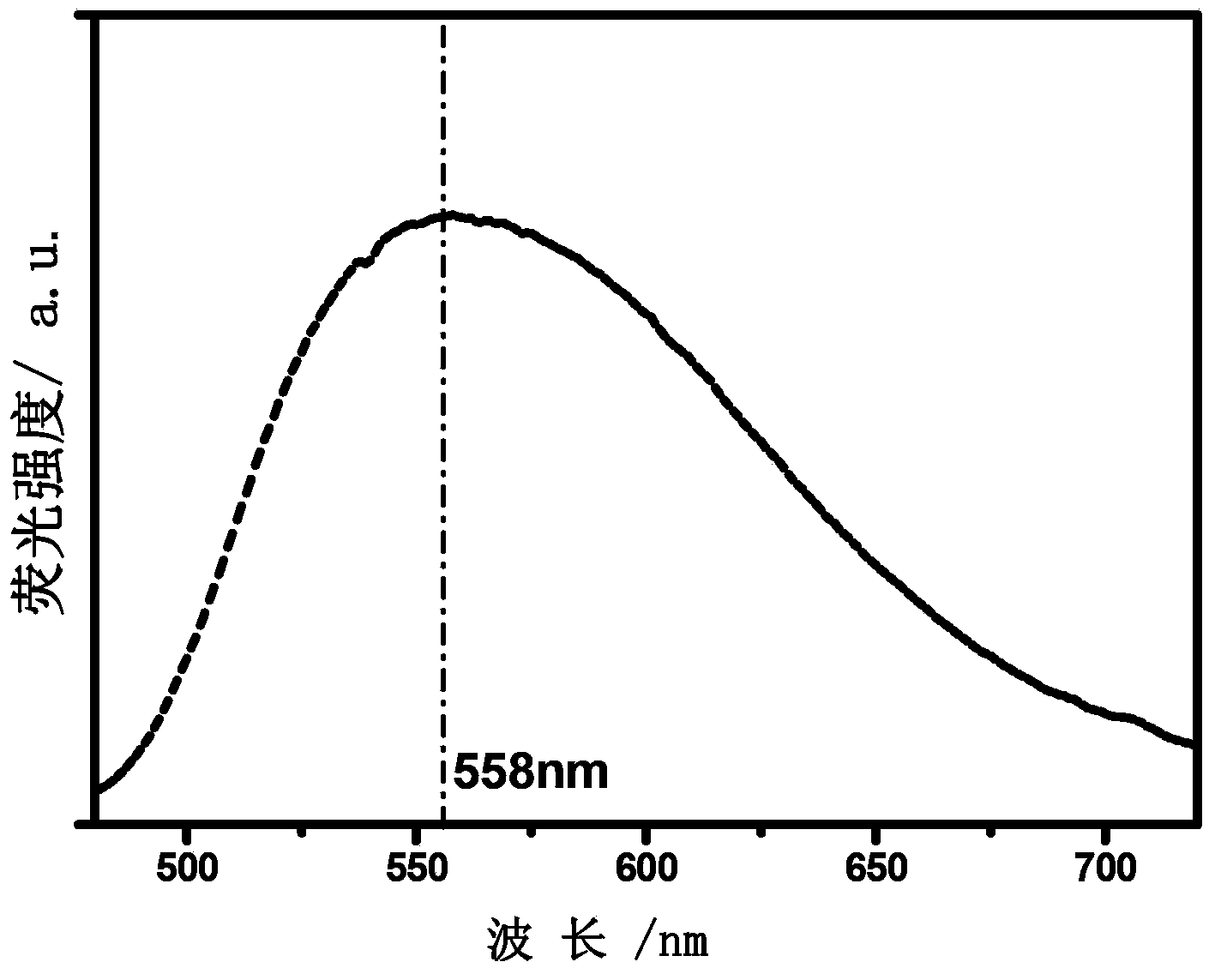

[0090] Using the green body obtained in Example 1, vacuum sintering is adopted. The specific process is: bury the green body in yttrium oxide powder (the particle size is greater than 10 microns after high-temperature burning), and keep the vacuum degree of the furnace body at 10 -3 Between Pa-0.02MPa (the requirement for vacuum degree is not high), then raise the temperature at 5°C° / min to 1250°C for 2 hours, then raise the temperature at 3°C / min to 1650°C for 5 hours, the surface is mechanically ground and Optically polished and annealed in air at 1200°C for 48 hours, the thickness of the obtained transparent ceramic is 1.5mm, the average grain size is about 9.4μm, the transmittance at the emission wavelength of 558nm is 69%, the decay time is 55ns; the density is 6.52 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com