Compound bacterium community capable of efficiently leaching sulphide ore, and compounding method and application method thereof

A technology of compound flora and application methods, applied in biochemical equipment and methods, microorganism-based methods, bacteria, etc., can solve the problems of long cycle, not widely used, slow bioleaching leaching speed, etc., to improve resistance, Strong exclusivity and good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

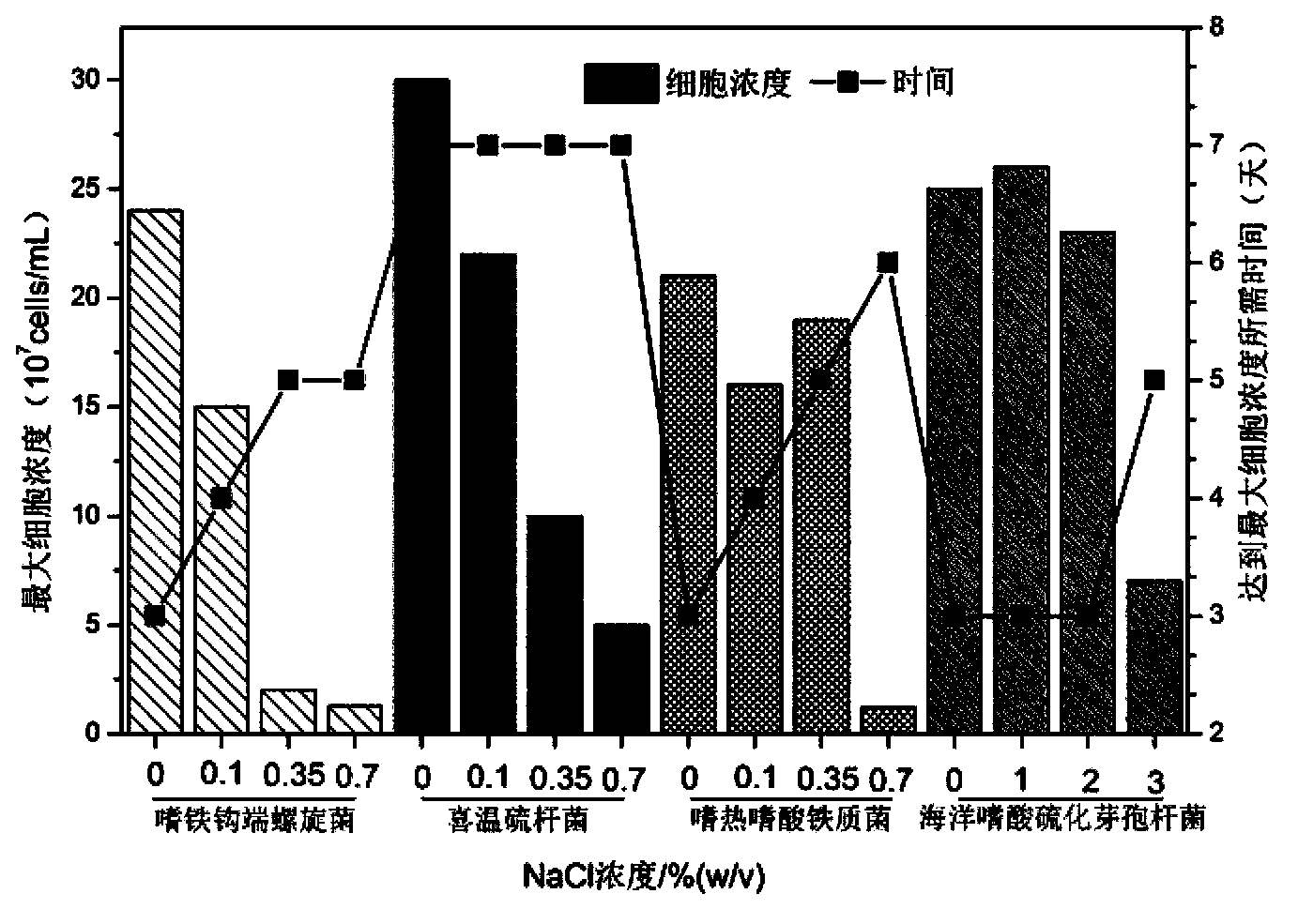

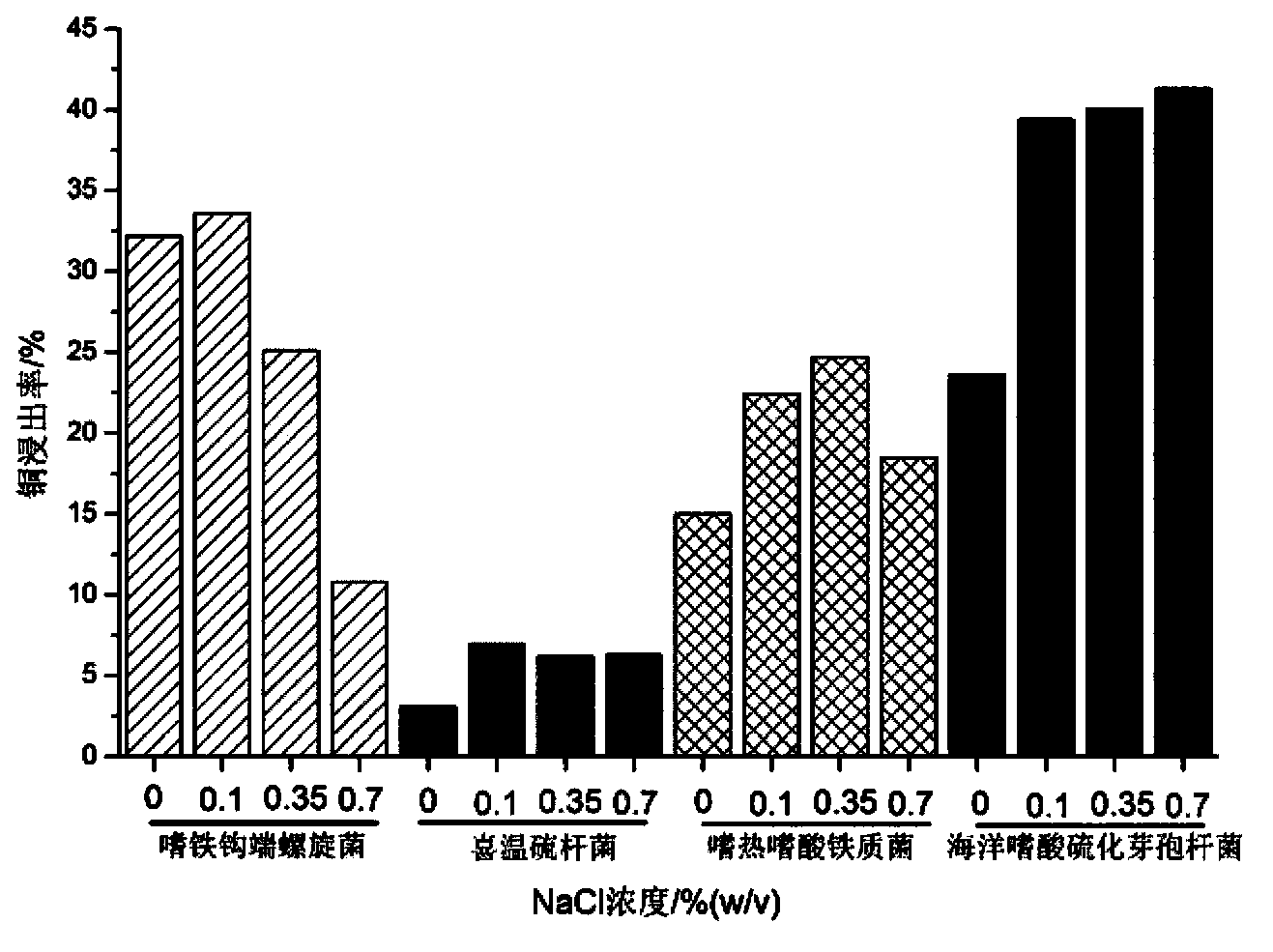

Embodiment 1

[0029] The sulfide ore used in this example comes from the Dongshengmiao Copper Mine in Inner Mongolia. The composition of the sulfide ore is as follows (w / w): chalcopyrite 60%, pyrrhotite 10%, sphalerite 15%, galena 5%. The leaching experiments were carried out in a stirred tank reactor with a slurry concentration of 10%. Acidophilus sulfurobacillus CCTCC NO:M2010203, Acidophilus ferrooxidans CCTCC AB207053, Acidophilus sulfuroxidans CCTCC AB206196, Acidophilus ferrooxidans CCTCC AB206158, Alberta acid sulfur rods used for inoculation Bacteria ATCC35403, Leptospira ferrobacter DSM14647, Mesophilic Sulfobacillus CCTCC AB207045, Thermophilic Thiobacillus CCTCC AB207044, Thermoacidophilic Ferrobacter CCTCC AB207143 T , Sulfolobus metallobus CCTCC AB207047, Metallococcus industriousness CCTCC AB206192, Acidbacterium manzae CCTCC AB207048 and Acidbacterium brucella CCTCC AB206222 were collected by centrifugation and mixed in proportion.

[0030] Before mixing, the various bacter...

Embodiment 2

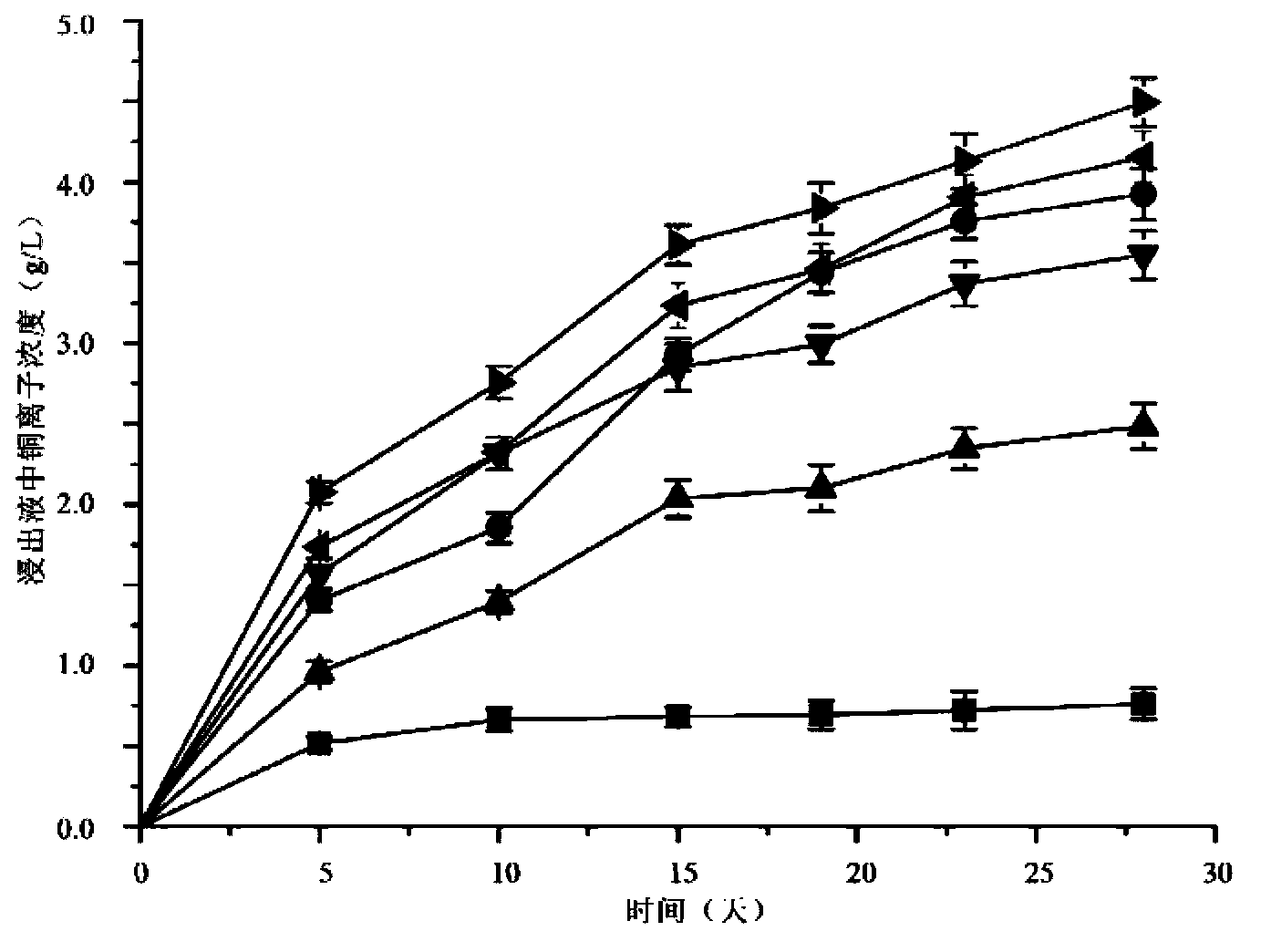

[0038] The low-grade sulfide ore used in this example is from the Yulong Copper Mine in Tibet, containing 2.95% copper. The copper phase distribution is (w / w): primary copper sulfide 21.36%, secondary copper sulfide 65.08%, free copper oxide 10.17%, combined copper oxide 3.39%.

[0039] Lay the bottom layer and anti-seepage layer. The bottom layer is coarse sand with a thickness of about 50 mm. On the anti-seepage layer, the pre-broken large-grained ore (15-25mm) is used as the buffer layer of the stockyard; continue to pile up the crushed small-grained ore (10-15mm); the heap height is 6-7m, the length The width is 20-25m each. After the pile is built, it is pre-sprayed with dilute sulfuric acid solution (pH 1.0-2.0). After the pH of the sprayed seepage is stabilized to 1.0-2.0, the method described in Example 1 is used for connection. The obtained mixed flora starts intermittent spraying; the spraying intensity is 10-15L / m 2 / h, after spraying for 10-16 hours, stop sprayi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com