Mixed carbohydrate-electrolyte injection and preparation method thereof

A technology of electrolyte injection and mixed sugar, which is applied in the direction of drug combination, pharmaceutical formula, and active ingredients of phosphorus compounds, etc., which can solve problems such as inability to ensure long-term stability, low 5-hydroxymethylfurfural, and increased production costs, so as to avoid Precipitation of crystals, simplification of process, and reduction of production time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

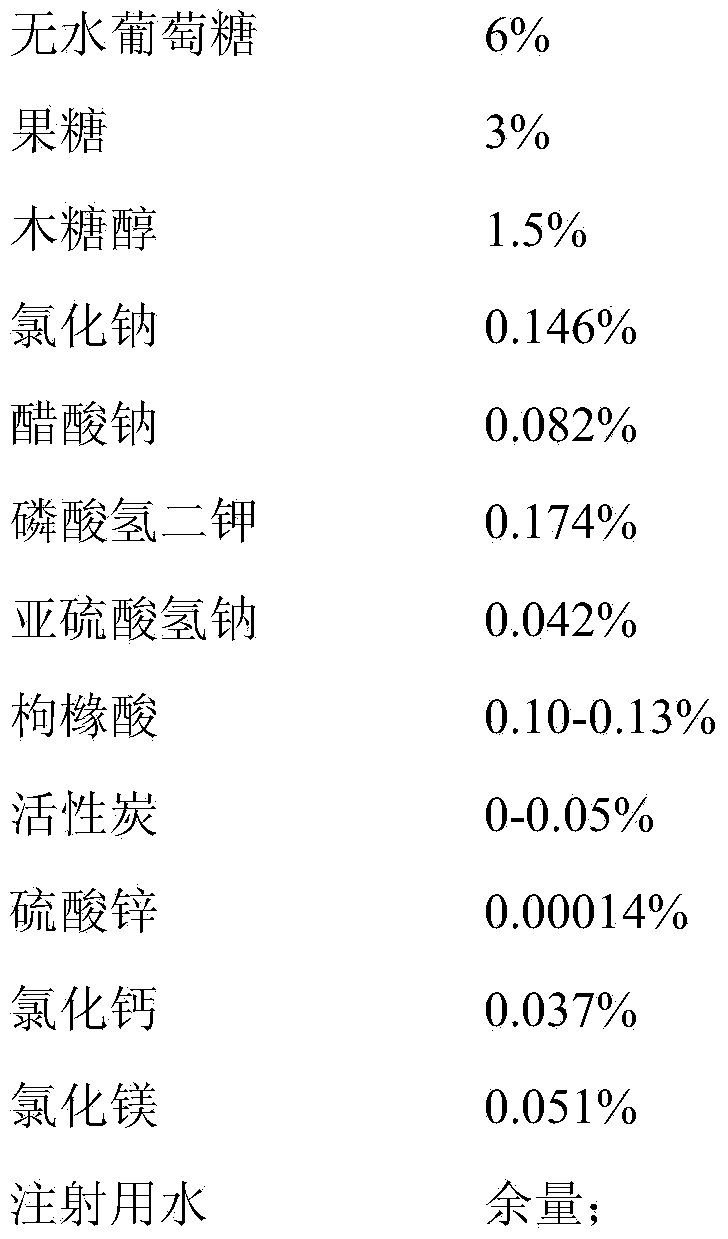

[0030] Mixed sugar electrolyte injection, the prescription is as follows:

[0031]

[0032]

[0033] The preparation steps are as follows:

[0034] (1) Add the prescribed amount of anhydrous glucose, fructose, xylitol, sodium chloride, sodium acetate, and dipotassium hydrogen phosphate to water for injection (80°C) in turn under nitrogen-filled conditions. After completely dissolving, use Citric acid to adjust the pH value, add activated carbon, stir, and filter to obtain the filtrate; the whole process controls the dissolved oxygen at 2-3ppm;

[0035] (2) Add the prescribed amount of zinc sulfate, calcium chloride, magnesium chloride and sodium bisulfite to the filtrate obtained in step (1) under the condition of nitrogen filling, stir, dissolve, and constant volume, and control the dissolved oxygen in the whole process at 2 -3ppm. Then filter with a 0.45 μm filter element and a 0.2 μm filter element in sequence, fill with nitrogen (residual oxygen content is less tha...

Embodiment 2

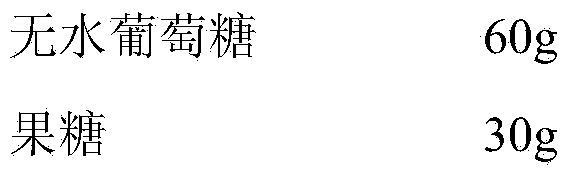

[0037] Mixed sugar electrolyte injection, the prescription is as follows:

[0038]

[0039]

[0040] The preparation steps are as follows:

[0041] (1) Add the prescribed amount of anhydrous glucose, fructose, xylitol, sodium chloride, sodium acetate, and dipotassium hydrogen phosphate to water for injection (80°C) in turn under nitrogen-filled conditions. After completely dissolving, use Citric acid to adjust the pH value, add activated carbon, stir, and filter to obtain the filtrate; the whole process controls the dissolved oxygen at 1-2ppm;

[0042] (2) Add the prescription amount of zinc sulfate, calcium chloride, magnesium chloride and sodium bisulfite to the filtrate obtained in step (1) under the condition of nitrogen filling, stir, dissolve, and constant volume, and control the dissolved oxygen in the whole process at 1 -2ppm. Then filter with a 0.45 μm filter element and a 0.2 μm filter element in sequence, fill with nitrogen (residual oxygen content is less t...

Embodiment 3

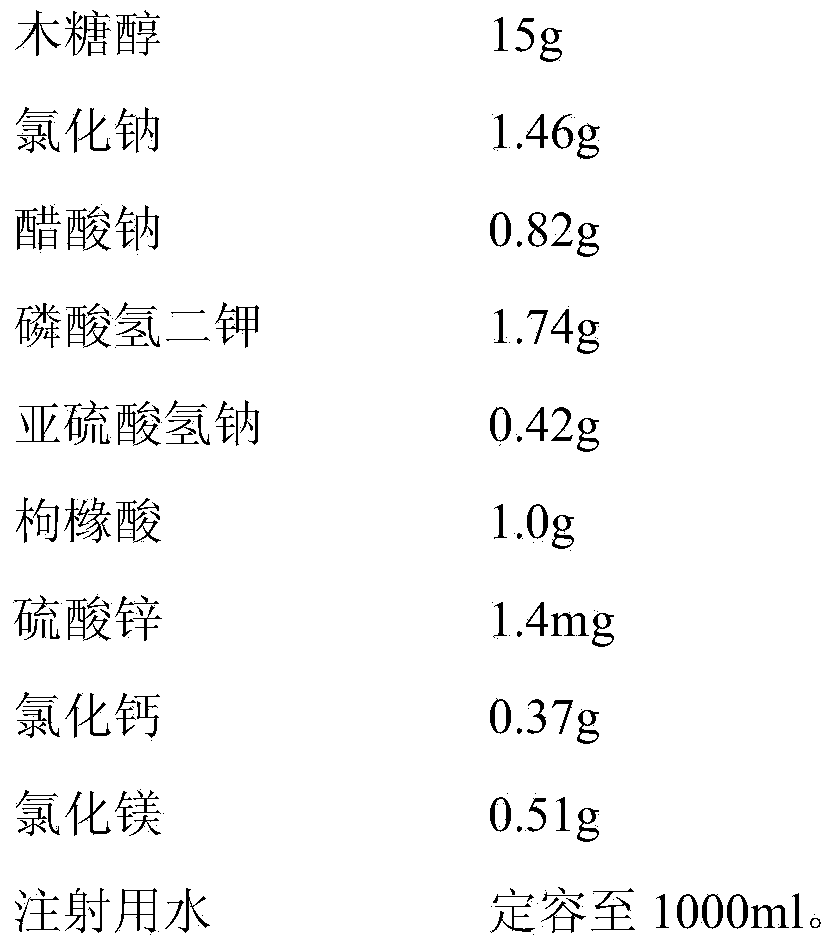

[0044] Mixed sugar electrolyte injection, the prescription is as follows:

[0045]

[0046] The preparation steps are as follows:

[0047](1) Add the prescribed amount of anhydrous glucose, fructose, xylitol, sodium chloride, sodium acetate, and dipotassium hydrogen phosphate to water for injection (75°C) in turn under nitrogen-filled conditions. After completely dissolving, use Citric acid to adjust the pH value, add activated carbon, stir, and filter to obtain the filtrate; the whole process controls the dissolved oxygen to be lower than 1ppm;

[0048] (2) Add the prescription amount of zinc sulfate, calcium chloride, magnesium chloride and sodium bisulfite to the filtrate obtained in step (1) under the condition of nitrogen filling, stir, dissolve, and constant volume, and control the dissolved oxygen in the whole process to be lower than 1ppm. Then filter with a 0.45 μm filter element and a 0.2 μm filter element in sequence, fill with nitrogen (residual oxygen content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com