Polybutadiene rubber modified waterborne polyurethane adhesive and preparation method thereof

A technology of polybutadiene rubber and water-based polyurethane, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., and can solve problems such as poor initial adhesive peel strength, high heat activation temperature, and low solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

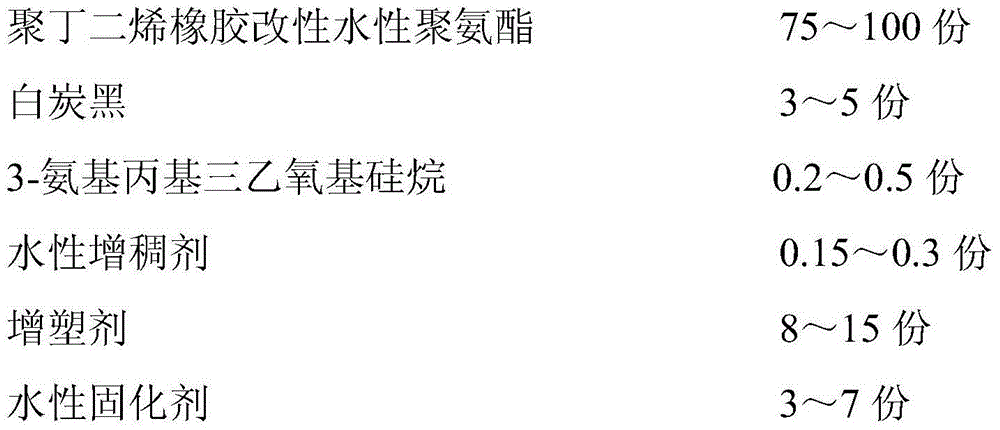

Method used

Image

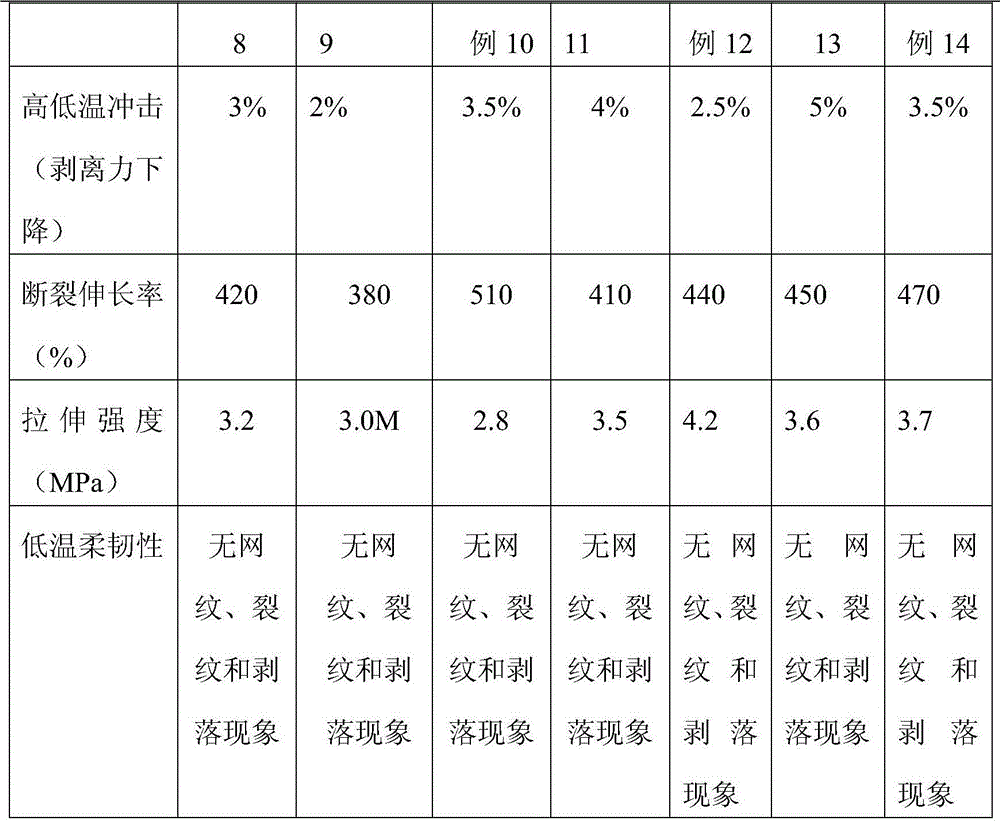

Examples

preparation example Construction

[0030] The preparation method of polybutadiene rubber modified waterborne polyurethane of the present invention includes:

[0031] Step 1: Reacting hydroxyl-terminated polybutadiene, polyester diol and diisocyanate to obtain the first intermediate;

[0032] Step 2: Reacting the first intermediate obtained in Step 1 with a small molecule chain extender to obtain a second intermediate;

[0033] Step 3: Reacting the second intermediate obtained in Step 2 with sodium ethylenediaminoethanesulfonate to obtain a polybutadiene rubber modified waterborne polyurethane.

[0034] As described in step one of the present invention, at room temperature, first add hydroxyl-terminated polybutadiene and polyester diol into the reaction kettle, dehydrate for 2 hours at a temperature of 100-120°C and -0.01 MPa, and then Then the diisocyanate is added dropwise to the reaction kettle to react to obtain the first intermediate; the reaction temperature is preferably 65-70°C, the reaction time is preferably 1...

Embodiment 1

[0046] At room temperature, add 2300g of hydroxyl-terminated polybutadiene (molecular weight of 2300 daltons) and 200g of polybutylene adipate (molecular weight of 2000 daltons) into the reaction kettle, and heat to 100°C. Dehydrate for 2 hours at 0.01 MPa, and cool to 65° C., then, drop 785 g of 1,6-hexamethylene diisocyanate at a rate of 10 ml / min. After the addition is complete, continue to react for 1.5 hours to obtain the first intermediate;

[0047] To the system of the first intermediate, 2250g of acetone was added to reduce the viscosity of the reaction system, 0.001g of dibutyltin dilaurate catalyst and 85g of 1,4-butanediol were added, the temperature rose to 75℃, and the reaction was continued for 2 hours , Get the second intermediate;

[0048] The temperature of the reaction system was lowered to 35°C, 122g of 95% sodium ethylenediamine ethanesulfonate aqueous solution was added at one time for chain extension, reacted for 15 minutes, then 3500g of deionized water was a...

Embodiment 2

[0050] At room temperature, add 4500g of hydroxyl-terminated polybutadiene (molecular weight of 4500 Daltons) and 500g of polybutylene adipate (molecular weight of 5000 Daltons) into the reaction kettle, and heat to 120°C. Dehydrate for 2 hours at 0.01 MPa, and cool to 70° C., then, drop 1350 g of dicyclohexylmethane diisocyanate at a rate of 15 ml / min. After the addition is complete, continue the reaction for 3 hours to obtain the first intermediate;

[0051] To the system of the first intermediate, 2785g of acetone was added to reduce the viscosity of the reaction system, 0.003g of stannous octoate catalyst and 136g of diethylene glycol were added, the temperature was raised to 80°C, and the reaction was continued for 4 hours to obtain the second Intermediate

[0052] The temperature of the reaction system was lowered to 45°C, 292g of 95% sodium ethylenediamine ethanesulfonate aqueous solution was added at one time to extend the chain, reacted for 25 minutes, and then 6200g of de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com