Preparation method of rice protein oligopeptides

A rice protein and oligopeptide technology, which is applied in the field of rice protein peptide preparation, can solve the problems of low proportion of active peptides in product molecular weight distribution, generation of harmful substances, and impact on the quality of polypeptide products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

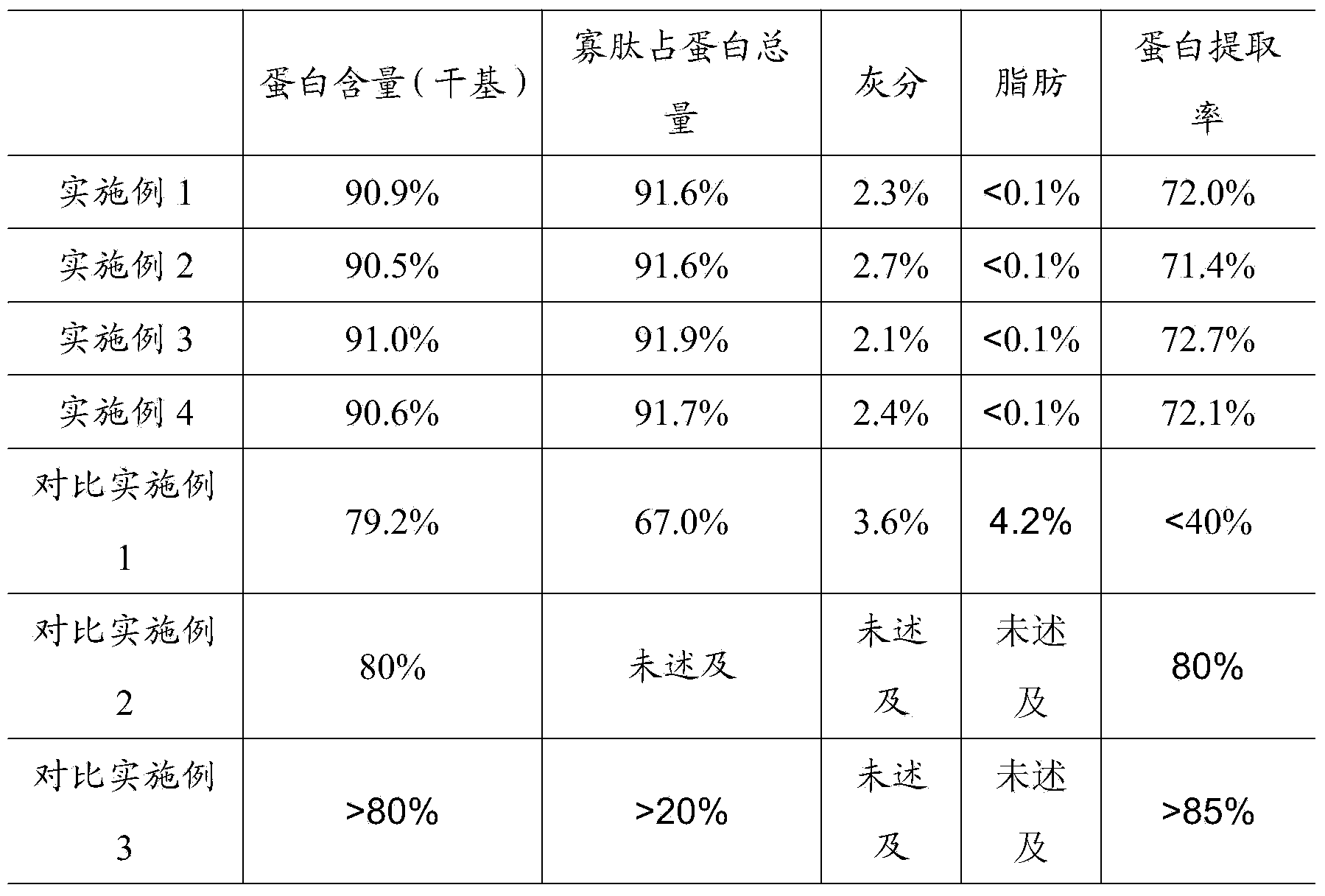

Examples

Embodiment 1

[0104] Embodiment 1: Adopt the method of the present invention to prepare rice protein oligopeptide

[0105] The implementation steps of this embodiment are as follows:

[0106] A. Raw material pretreatment

[0107] Using a pulverizer sold by Jiangyin Weida Pharmaceutical Machinery Manufacturing Co., Ltd., crush 1000 kg of rice dregs (protein content 52.4% and moisture content 4.2% based on the total weight of rice dregs) sold by Jiangxi Hengtian Industrial Co., Ltd. to 100- 120 mesh, obtain a kind of rice dregs powder;

[0108] B. Mixing

[0109] Add water to the rice dregs powder to obtain a feed liquid with a protein concentration of rice dregs of 18% by weight, then adjust the pH of the feed liquid to 7.3 with a 10% NaOH aqueous solution by weight, and then use The plate heat exchanger sold by Nanhua Heat Exchanger Manufacturing Co., Ltd. was heated to a temperature of 75°C, and reacted at this temperature for 1.5h; then the plate heat exchanger sold by Shanghai Nanhua ...

Embodiment 2

[0123] Embodiment 2: Adopt the method of the present invention to prepare rice protein oligopeptide

[0124] The implementation steps of this embodiment are as follows:

[0125] A. Raw material pretreatment

[0126] Using a pulverizer sold by Jiangyin Haike Powder Equipment Manufacturing Co., Ltd., crush 1500kg of rice dregs (protein content 54.1% and moisture content 4.7% based on the total weight of rice dregs) sold by Jiangxi Zhongchao Biotechnology Co., Ltd. to 100~ 120 mesh, obtain a kind of rice dregs powder;

[0127] B. Mixing

[0128] Add water to the rice dregs powder to obtain a feed liquid with a rice dregs protein concentration of 22% by weight, then adjust the pH value of the feed liquid to 7.5 with 10% NaOH aqueous solution by weight, and then use Heat the plate heat exchanger sold by Tianjin Heat Exchange Equipment General Factory Co., Ltd. to a temperature of 80°C, and react at this temperature for 2.0h; then use the plate heat exchanger sold by Tianjin Heat...

Embodiment 3

[0142] Embodiment 3: Adopt the method of the present invention to prepare rice protein oligopeptide

[0143] The implementation steps of this embodiment are as follows:

[0144] A. Raw material pretreatment

[0145] Using a pulverizer sold by Jiangyin Longchang Machinery Manufacturing Co., Ltd., 1800 kg of rice dregs (protein content 52.6% and moisture content 4.0% based on the total weight of rice dregs) sold by Wuhan Jindege Sugar Industry Co., Ltd. were pulverized to 100 ~120 mesh, a kind of rice dregs powder is obtained;

[0146] B. Mixing

[0147] Add water to the rice dregs powder to obtain a feed liquid with a rice dregs protein concentration of 18% by weight, then adjust the pH value of the feed liquid to 7.3 with a 10% NaOH aqueous solution by weight, and then use The plate heat exchanger sold by Changzhou Shengge Heat Exchanger Co., Ltd. was heated to a temperature of 75° C., and reacted at this temperature for 1.5 h; The temperature of the liquid drops to 50°C; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com