Metal vacuum insulated panel and preparation method thereof

A vacuum insulation panel and metal plate technology, which is used in insulation improvement, climate change adaptation, building components and other directions, can solve the problems of complex construction process, cost of insulation layer tiles falling off, and high moisture content of core materials, shortening the construction period, The effect of weight reduction and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

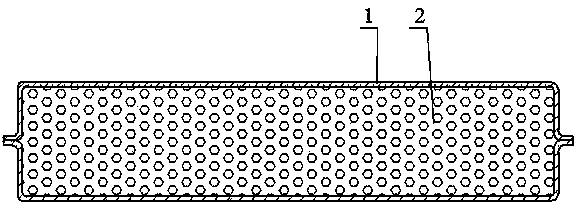

[0030] Example 1: see figure 1 , The metal vacuum insulation board is composed of a shell 1 and a core material 2. The shell 1 is composed of thin metal plates such as stainless steel plate, galvanized plate, tin plate or aluminum alloy plate with a thickness of 0.15-1.5mm; the core material 2 is glass fiber, For pearl sand, perlite, vermiculite, aerogel, etc., the core material 1 is preferably subjected to treatments such as drying, plastic bag packaging, and pre-vacuuming. The manufacturing method of the metal vacuum insulation board is as follows: First, cut two stainless steel plates of the same size with a thickness of 0.3mm to make the housing 1, and use the stamping method to fold the two stainless steel plates; secondly, use a certain size of pearl sand Or perlite, etc. are dried in a continuous kiln, put into a plastic bag, vacuumed and sealed to make it a core material 2 with a smaller volume and a certain shape; again, put the packed core material 2 into two A compos...

Embodiment 2

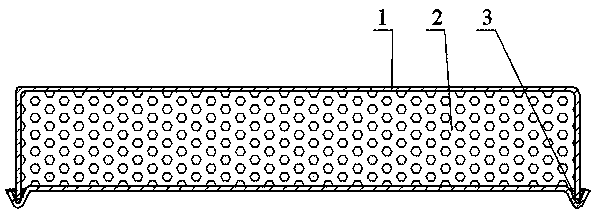

[0031] Example 2: See Example 1 and figure 2 , Basically the same as embodiment 1, the difference is that the metal plate forming the shell 1 is directly punched out of the groove for edge sealing during the stamping and forming, and low-temperature metal solder such as tin, zinc, magnesium and its low melting point alloy is placed in the groove , Through brazing in the vacuum furnace to complete the air-tight seal of the shell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com