Memory unit of low-power resistive random access memory and preparation method of memory unit

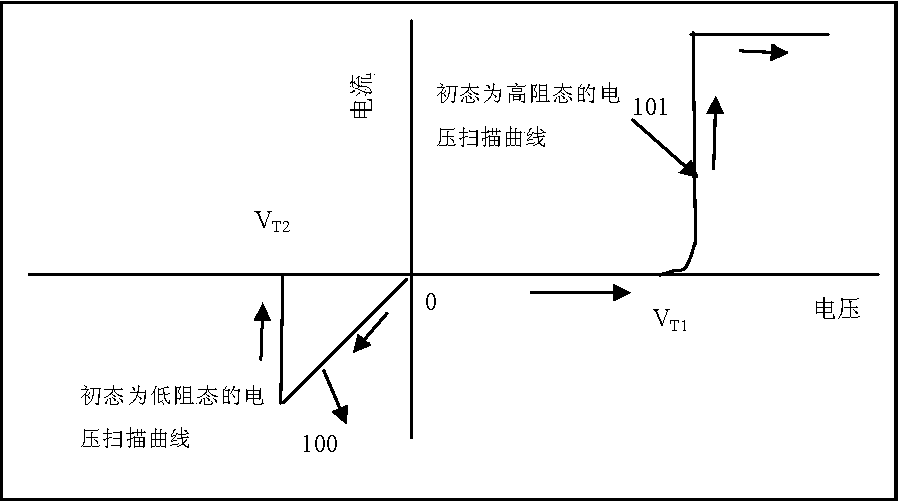

A resistive random and storage unit technology, applied in static memory, digital memory information, electrical components, etc., can solve the problems of complex metal oxide formation process, pollution, and difficult control of film composition ratio, so as to reduce reset Operating current and reading current, increasing the resistance value, and reducing the effect of reading and writing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) On a clean silicon substrate, grow a layer of silicon oxide by thermal oxidation, and then use acetone to sonicate, and then heat and clean it in a cleaning solution of ammonia water plus hydrogen peroxide, hydrochloric acid and hydrogen peroxide. The thermal oxidation temperature is 900-1100°C, and the SiO produced by thermal oxidation 2 The layer thickness is 400-600 nm.

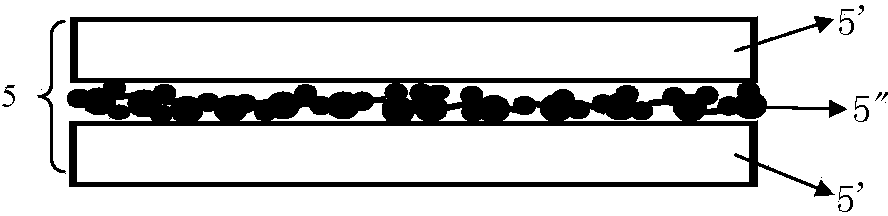

[0064] (2) Deposit the bottom electrode on the cleaned surface. The material of the bottom electrode film can be any one of Pt, Au, Ni, Ti, W, Mo, Al, Ag-Al alloy, ITO or FTO. The thickness of the bottom electrode film is 50-100nm.

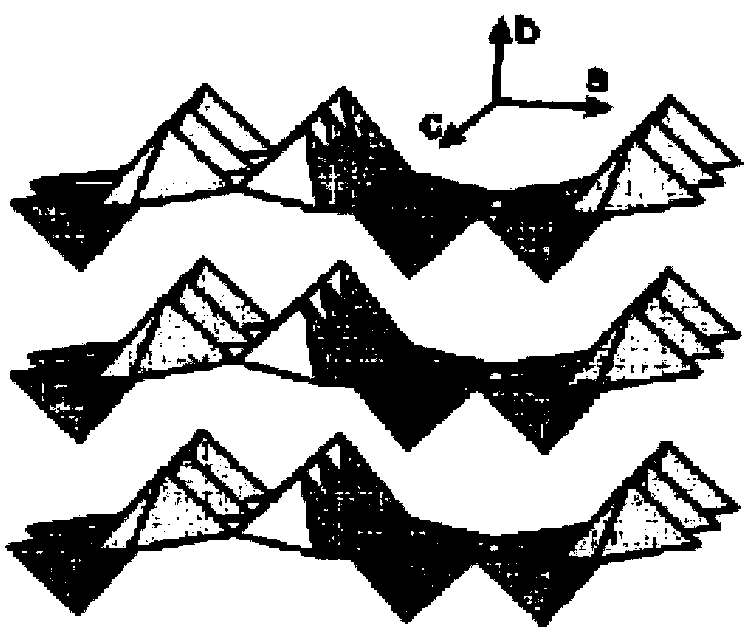

[0065] (3) Weigh the analytically pure V 2 o 5 Powder, high purity and good stability V 2 o 5 Sol.

[0066] (4) Molar ratio (aniline: V 2 o 5 ) is 0.25:1, weigh 1ml aniline, add 10ml water to make a solution, add monomer dropwise and add 50mlV 2 o 5 In the sol, stir fully on a magnetic stirrer at room temperature, react for 24 hours, and finally form dark ...

Embodiment 2

[0074]Replace the aniline in step (4) in Example 1 with dodecylamine for intercalation reaction, and then photolithography and etching in the upper end region of the tubular electrode to form a multilayer film unit composed of a storage film and an intercalation composite film block as a storage medium. Others are similar to Embodiment 1, and similar effects can also be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com