Two-component silicone-acrylic emulsion anti-mildew coating and preparation method thereof

A silicone acrylic emulsion, two-component technology, used in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problem of rising mold spores and film-forming substrates that may be brought into the air Insufficient density, high price and other problems, to achieve the effect of environmental adaptability, improved anti-mildew effect and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

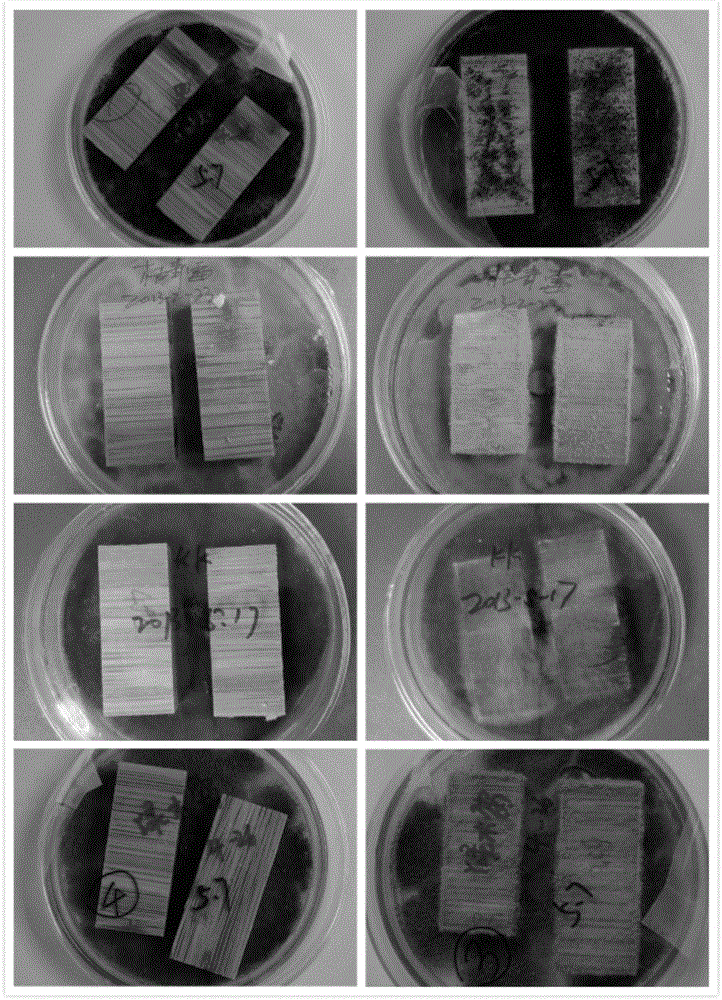

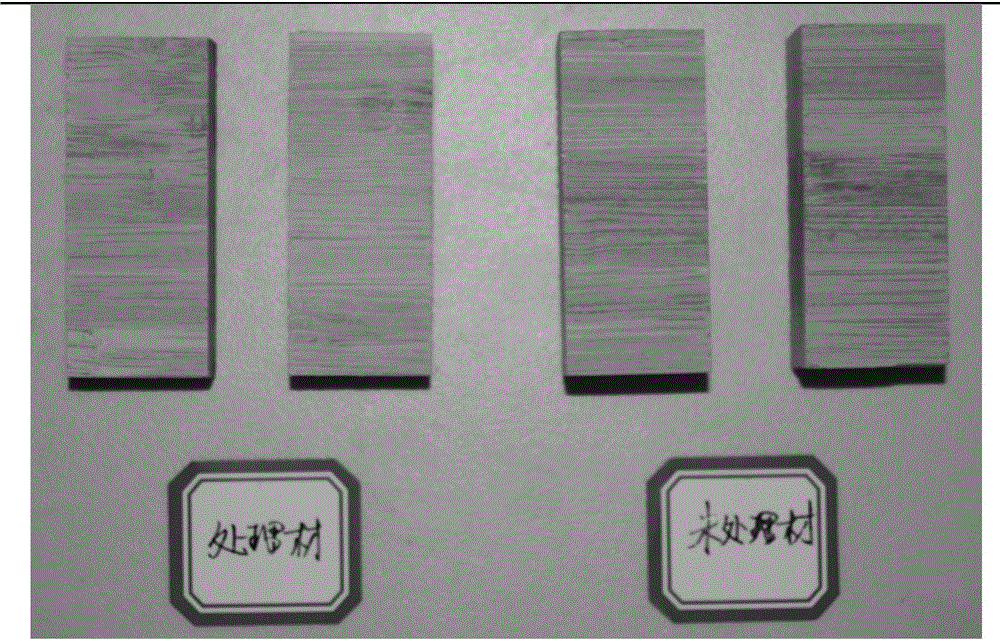

Image

Examples

Embodiment 1

[0029] 1) Preparation and synthesis of silicone acrylic emulsion:

[0030] Weigh 56 g of methyl acrylate, 2 g of acrylic acid, 1 g of emulsifier fatty alcohol polyoxyethylene ether sodium sulfate and alkylphenol polyoxyethylene (10) ether OP-10, 1 g of sodium bicarbonate, 1 g of propylene glycol, and 50 g of water Gram; Emulsify uniformly at a high speed of 1500rpm at room temperature to prepare a component A emulsion;

[0031] Weigh 38 grams of n-butyl acrylate, 14 grams of vinyl triethoxysilane, 1 gram each of emulsifier fatty alcohol polyoxyethylene ether sodium sulfate AES and alkylphenol polyoxyethylene (10) ether OP-10, bicarbonate 1 gram of sodium, 1 gram of propylene glycol, and 50 grams of water were emulsified evenly at a high speed of 1500 rpm at room temperature to prepare a component B emulsion;

[0032] Weigh 40 grams of liquid A that has been emulsified uniformly, add 2 milliliters of potassium persulfate aqueous solution with a mass fraction of 20%, slowly rai...

Embodiment 2

[0036] 1) Preparation and synthesis of silicone acrylic emulsion:

[0037] Weigh 54g of methyl methacrylate, 4g of methacrylic acid, 1 gram of emulsifier fatty alcohol polyoxyethylene ether sodium sulfate and alkylphenol polyoxyethylene (10) ether OP-10, 1 gram of potassium bicarbonate, 1 gram of propylene glycol gram, 60 grams of water; emulsify evenly at a high speed at 1500rpm at room temperature to prepare a component A emulsion;

[0038] Take by weighing 42 grams of n-butyl methacrylate, 10 grams of vinyl triethoxysilane, 1 gram each of emulsifier fatty alcohol polyoxyethylene ether sodium sulfate AES and alkylphenol polyoxyethylene (10) ether OP-10, 1 gram of potassium bicarbonate, 1 gram of n-amyl alcohol, and 40 grams of water were uniformly emulsified at a high speed of 1500 rpm at room temperature to obtain a component B emulsion;

[0039]Weigh 40 grams of liquid A that has been emulsified uniformly, add 2 ml of potassium persulfate aqueous solution with a mass frac...

Embodiment 3

[0043] 1) Preparation and synthesis of silicone acrylic emulsion:

[0044] Take by weighing methyl acrylate 52g, acrylic acid 6g, emulsifier fatty alcohol polyoxyethylene ether sodium sulfate and alkylphenol polyoxyethylene (10) ether OP-10 each 1 gram, sodium bicarbonate 1 gram, ethylene glycol 1 gram, 40 grams of water; uniformly emulsified at a high speed of 1500 rpm at room temperature to obtain component A;

[0045] Take by weighing 40 grams of n-butyl methacrylate, 12 grams of vinyl triethoxysilane, 1 gram each of emulsifier fatty alcohol polyoxyethylene ether sodium sulfate AES and alkylphenol polyoxyethylene (10) ether OP-10, 1 gram of sodium bicarbonate, 1 gram of dibutyltin dilaurate, and 60 grams of water were emulsified at room temperature at a high speed of 1500 rpm to obtain component B;

[0046] Weigh 40 grams of liquid A that has been emulsified uniformly, add 3 ml of potassium persulfate aqueous solution with a mass fraction of 10%, slowly raise the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com