Aqueous enzymatic method for extracting rapeseed oil and recovering protein

A rapeseed oil and protein technology, which is applied in the production, fermentation, and fat production of fat oil/fat, can solve the problems of low oil-containing protein, difficult demulsification and separation, low oil yield, etc., and achieves less environmental pollution and simple process equipment. , The effect of improving oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

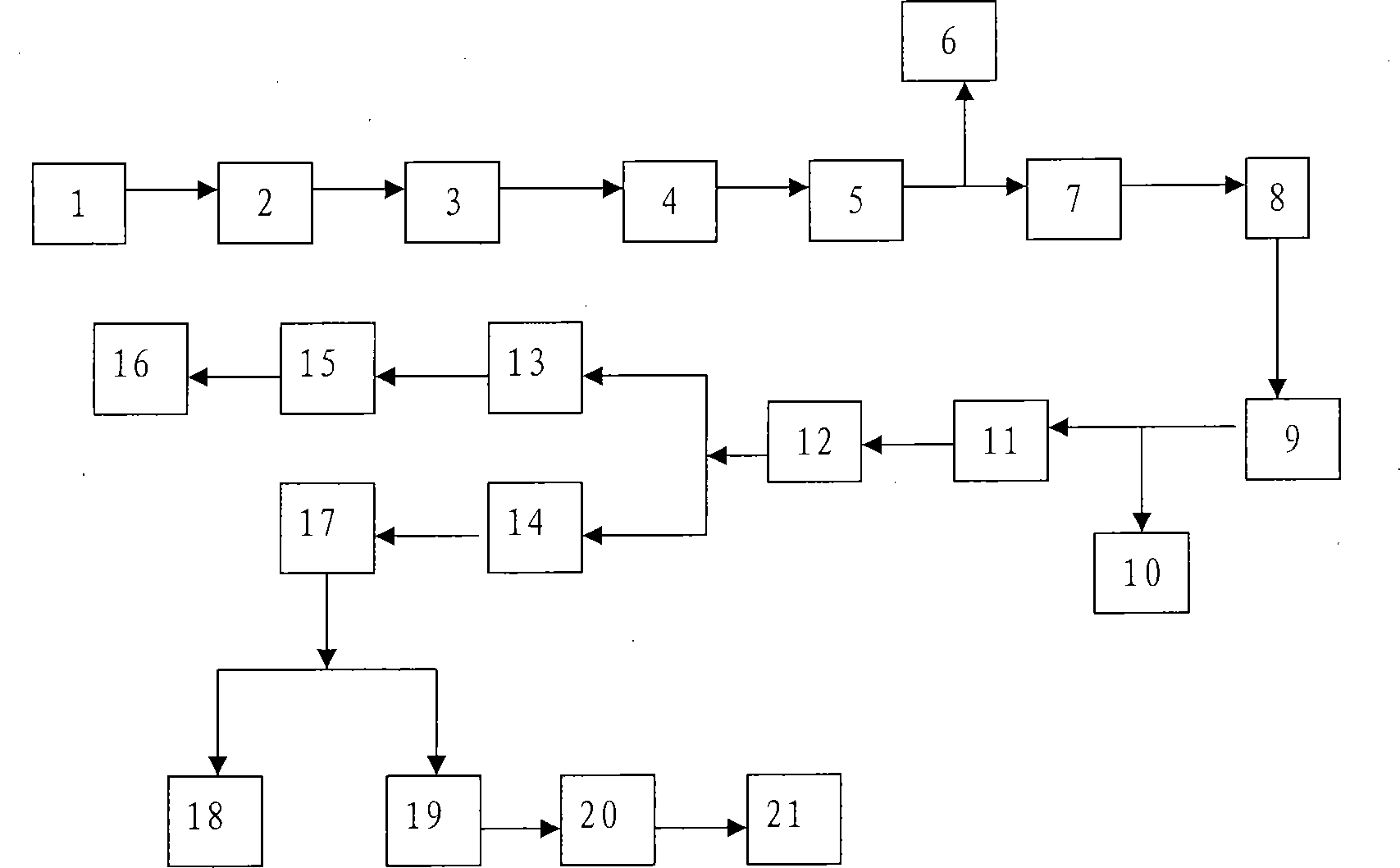

Method used

Image

Examples

Embodiment 1

[0027] 1) Raw material processing: the raw rapeseed is crushed into rapeseed cake according to the conventional method, and the citric acid solution with pH 4.5-5.5 is soaked at high temperature (80-120℃) for 0.1-2h, and then the solid-liquid ratio is 1:2-1 :20 Replenish citric acid solution, refining, plate and frame filtration to separate and remove the crust. The material liquid is cooled to 30-60°C.

[0028] 2) Enzymatic hydrolysis: add 50-500U / g composite cellulase according to the dry weight of rapeseed, enzymatically hydrolyze at 30-60℃ for 2-6h, then add 100-500U / g acid protease, enzymatically hydrolyze at 30-60℃ 2- 6h. After the enzymolysis is completed, the temperature is raised to 80-120°C and kept for 5-10min to inactivate the enzyme.

[0029] 3) Residue separation: the enzymatic hydrolysis solution is separated by a horizontal centrifuge to obtain liquid phase 1 and the residue.

[0030] 4) Demulsification: Add concentrated sulfuric acid to liquid phase 1 to adjust th...

Embodiment 2

[0034] 1) Raw material processing: The raw rapeseed is crushed into rapeseed cake according to the conventional method, and the acetic acid solution with pH 4.5-5.5 is soaked at high temperature (80-120℃) for 0.1-2h, and then the solid-liquid ratio is 1:2-1: 20 Supplement acetic acid, refining, plate and frame filtration to separate and remove the skin. The material liquid is cooled to 30-60°C.

[0035] 2) Enzymatic hydrolysis: add 50-500U / g composite cellulase according to the dry weight of rapeseed, enzymatically hydrolyze at 30-60℃ for 2-6h, then add 100-500U / g neutral protease and xylanase composite enzyme , Enzymatic hydrolysis at 30-60℃ for 2-6h. After the enzymolysis is completed, the temperature is raised to 80-120°C and kept for 5-10min to inactivate the enzyme.

[0036] 3) Residue separation: the enzymatic hydrolysis solution is separated by a horizontal centrifuge to obtain liquid phase 1 and the residue.

[0037] 4) Demulsification: Add sodium chloride solid to liquid ...

Embodiment 3

[0041] 1) Raw material processing: The raw rapeseed is crushed into rapeseed cake according to the conventional method, and soaked in 0.01M phosphoric acid solution at high temperature (80-120℃) for 0.1-2h, and then supplemented with phosphoric acid according to the solid-liquid ratio 1:2-1:20 Solution, refining, plate and frame filtration to separate and remove the skin shell. The material liquid is cooled to 30-60°C.

[0042] 2) Enzymatic hydrolysis: add 50-500U / g composite cellulase according to the dry weight of rapeseed, enzymatically hydrolyze at 30-60℃ for 2-6h, then add 100-500U / g trypsin and pectinase composite enzyme, 30 Enzymatic hydrolysis at -60℃ for 2-6h. After the enzymolysis is completed, the temperature is raised to 80-120°C and kept for 5-10min to inactivate the enzyme.

[0043] 3) Residue separation: the enzymatic hydrolysis solution is separated by a horizontal centrifuge to obtain liquid phase 1 and the residue.

[0044] 4) Demulsification: Add polyacrylamide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com