Li2C6O6 composite material and preparation method thereof

A composite material, graphene technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of low power density, inability to perform high current charge and discharge, short life, etc., to achieve high capacity, excellent conductivity and Excellent thermal stability and energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

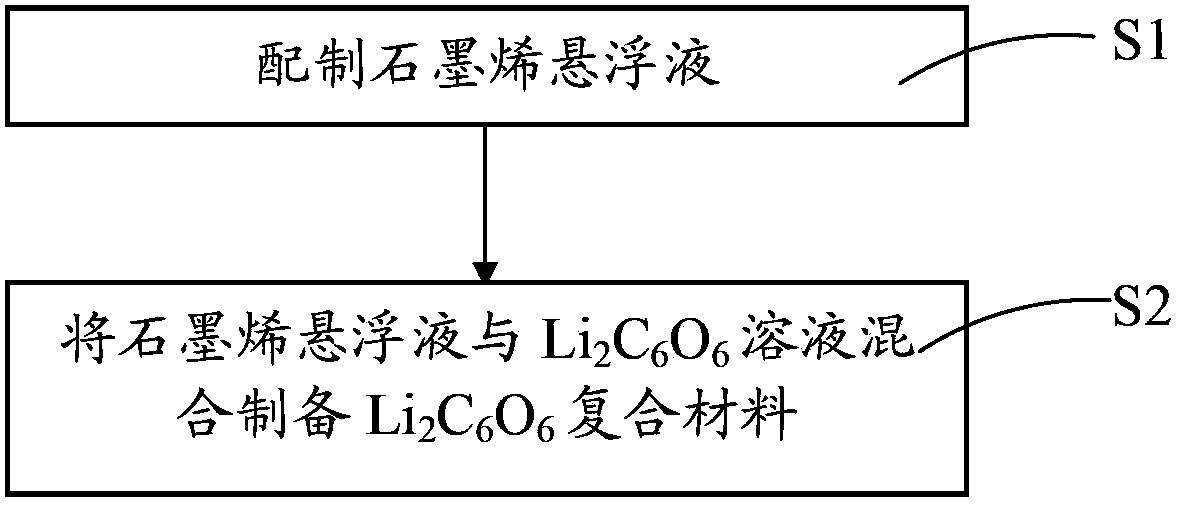

[0022] Examples of the present invention also provide a simple process, high efficiency, easy to operate and control the above Li 2 C 6 o 6 Methods of preparation of composite materials. The Li 2 C 6 o 6 For the preparation method and process flow of composite materials, please refer to figure 1 , the method includes the following steps:

[0023] S01, prepare graphene suspension: obtain graphene, and prepare graphene suspension;

[0024] S02, the graphene suspension and Li 2 C 6 o 6 Solution mixing to prepare Li 2 C 6 o 6 Composite material: the graphene suspension prepared in step S01 was mixed with Li 2 C 6 o 6 After the solutions were mixed, they were vacuum-dried to obtain the Li 2 C 6 o 6 composite materials, in which graphene accounts for the Li 2 C 6 o 6 30% to 60% of the total mass of composite materials.

[0025] Specifically, the preparation method of the graphene suspension in the above step S01 is preferably: dispersing the graphene in the aqu...

Embodiment 1

[0047] A kind of Li 2 C 6 o 6 Composite material and preparation method thereof, the specific steps of its preparation method are as follows:

[0048] S11. Provide graphite: purity 99.5%.

[0049] S12. Preparation of graphite oxide: graphite oxide was prepared by the improved Hummers method (extracted from JACS, 1958, 80, 1339). The specific steps are adding 20g of 50 mesh graphite powder, 10g of potassium persulfate and 10g of phosphorus pentoxide into concentrated sulfuric acid at 80°C, stirring evenly, cooling for more than 6h, washing until neutral, and drying. Add the dried sample to 230mL of concentrated sulfuric acid at 0°C, then add 60g of potassium permanganate, keep the temperature of the mixture below 20°C, then keep it in an oil bath at 35°C for 2h, then slowly add 920mL of deionized water . After 15 minutes, add 2.8L of deionized water (which contains 50mL of 30% hydrogen peroxide), and then the color of the mixture turns bright yellow. Suction filtration whi...

Embodiment 2

[0053] A kind of Li 2 C 6 o 6 Composite material and preparation method thereof, the specific steps of its preparation method are as follows:

[0054] S21. Provide graphite: the purity is 99.5%.

[0055] S22. Preparation of graphite oxide: Graphite oxide was prepared by the improved Hummers method (from JACS, 1958, 80, 1339); by the improved Hummers method (Hummers W S, Offeman R E.[J].J Am Chem Soc,1958, 80:133921339) for the preparation of graphite oxide. The specific steps are adding 20g of 50 mesh graphite powder, 10g of potassium persulfate and 10g of phosphorus pentoxide into concentrated sulfuric acid at 80°C, stirring evenly, cooling for more than 6h, washing until neutral, and drying. Add the dried sample to 230mL of concentrated sulfuric acid at 0°C, then add 60g of potassium permanganate, keep the temperature of the mixture below 20°C, then keep it in an oil bath at 35°C for 2h, then slowly add 920mL of deionized water . After 15 minutes, add 2.8L of deionized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com