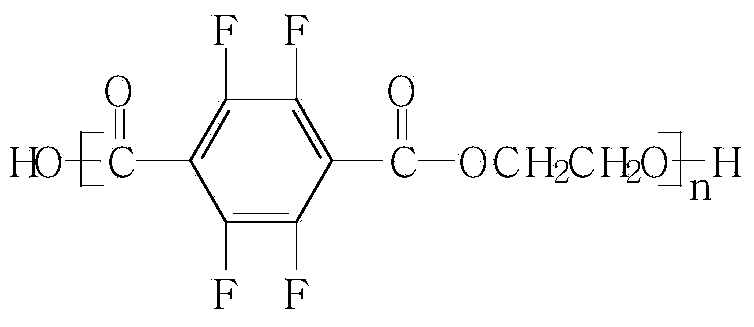

Fluorinated polyester polyester pre-oriented yarn (POY) fibers and preparation method thereof

A technology of fluorine polyester and fluorine-containing polyester is applied in the field of fluorine polyester POY fiber and its preparation, and achieves the effects of solving the problem of timeliness, good heat resistance and low refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A preparation method of fluoropolyester is divided into two steps of esterification reaction and polycondensation reaction. The specific steps are:

[0069] Described esterification reaction:

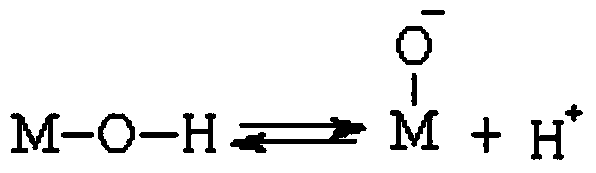

[0070] Ethylene glycol and tetrafluoroterephthalic acid with a molar ratio of 1.2:1 are used as raw materials, and magnesium oxide of 0.01% of the weight of tetrafluoroterephthalic acid is added at the same time to make a uniform slurry and carry out esterification reaction; esterification reaction In a nitrogen atmosphere, the pressure is controlled at 0.4MPa, the temperature is controlled at 250°C, and the distilled amount of esterification water reaches 90% of the theoretical value, which is the end point of the esterification reaction.

[0071] Described polycondensation reaction:

[0072] Including low vacuum stage of polycondensation reaction and high vacuum stage of polycondensation reaction:

[0073] In the low-vacuum stage of the polycondensation reaction, 0.01% of th...

Embodiment 2

[0078] A preparation method of fluoropolyester is divided into two steps of esterification reaction and polycondensation reaction. The specific steps are:

[0079] Described esterification reaction:

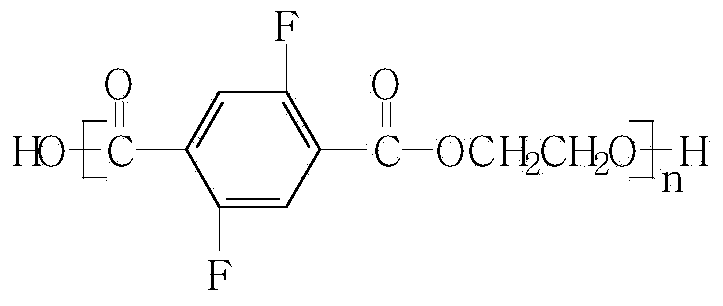

[0080] Use ethylene glycol and 2,5-difluoroterephthalic acid with a molar ratio of 1.4:1 as raw materials, and add 0.02% silicon oxide based on the weight of 2,5-difluoroterephthalic acid at the same time to prepare a uniform slurry Carry out esterification reaction; the esterification reaction is pressurized in a nitrogen atmosphere, the pressure is controlled at 0.3MPa, the temperature is controlled at 245°C, and the distilled amount of esterification water reaches 90% of the theoretical value, which is the end point of the esterification reaction.

[0081] Described polycondensation reaction:

[0082] Including low vacuum stage of polycondensation reaction and high vacuum stage of polycondensation reaction:

[0083] In the low vacuum stage of the polycondensation reaction, ...

Embodiment 3

[0088] A preparation method of fluoropolyester is divided into two steps of esterification reaction and polycondensation reaction. The specific steps are:

[0089] Described esterification reaction:

[0090] Use ethylene glycol and tetrafluoroterephthalic acid with a molar ratio of 1.6:1 as raw materials, and add 0.03% calcium oxide based on the weight of tetrafluoroterephthalic acid at the same time, make a uniform slurry and carry out esterification reaction; esterification reaction Pressurize in a nitrogen atmosphere, control the pressure at 0.2MPa, control the temperature at 240°C, and the esterification water distillate reaches 90% of the theoretical value, which is the end point of the esterification reaction.

[0091] Described polycondensation reaction:

[0092] Including low vacuum stage of polycondensation reaction and high vacuum stage of polycondensation reaction:

[0093] In the low vacuum stage of the polycondensation reaction, 0.03% of the catalyst antimony a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com