Light trapping structure on silicon substrate surface, preparation method and application thereof

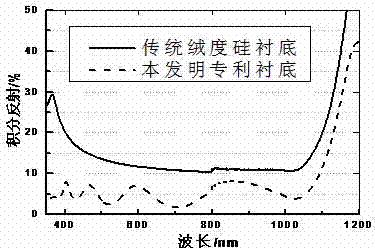

A light trapping structure, silicon substrate technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., to achieve the effect of reducing reflection, increasing absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

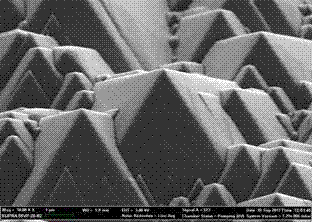

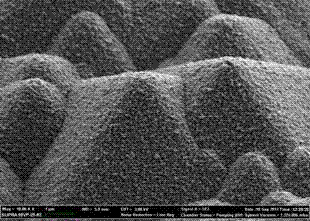

[0027] A method for preparing a light-trapping structure on the surface of a silicon substrate, first using NaOH, IPA and NaSiO 3 Carry out texturing, then use hydrofluoric acid and other reagents for smoothing, and finally use MOCVD technology to deposit nano-sized pyramids on the texturing silicon wafer to obtain a light-trapping structure that improves the surface of the silicon substrate. The steps are as follows:

[0028] 1) Place the silicon wafer in ethanol / acetone and sonicate for 5 minutes each to remove organic matter;

[0029] 2) Place the cleaned silicon wafer in a sodium hydroxide solution, heat the solution to 80°C, and react for 20 minutes to remove the damaged layer;

[0030] 3) Place the above silicon wafer in 74g of NaOH with a mass percentage concentration of 1%, 444ml of isopropanol with a volume percentage concentration of 6%, and 74g of NaSiO with a mass percentage concentration of 1%. 3 Add 6000ml of deionized water to the mixed solution of deionized wa...

Embodiment 2

[0037] A method for preparing a light-trapping structure on the surface of a silicon substrate, steps 1)-5) are the same as in Example 1, except for step 6):

[0038] 6) Put the Smooth-treated silicon wafer in the deposition chamber of MOCVD, the deposition temperature is 170°C, the flow rate of water vapor is 110 sccm, and the flow rate of DEZn is 180 sccm, B 2 h 6 The flow rate is 3 sccm, the deposition gas pressure is 1 Torr, the deposition time is 5 min, and the thickness of the ZnO layer is 300 nm, so that the light-trapping structure that improves the surface of the silicon substrate can be prepared.

[0039] The technical effect of the light trapping structure is similar to that of Embodiment 1.

Embodiment 3

[0041] A method for preparing a light-trapping structure on the surface of a silicon substrate, steps 1)-5) are the same as in Example 1, except for step 6):

[0042] 6) Place the processed silicon wafer in the deposition chamber of MOCVD, the deposition temperature is 177°C, H 2 O steam flow is 130sccm, DEZn flow is 180sccm, B 2 h 6 The flow rate is 0 sccm, the deposition gas pressure is 0.8 Torr, the deposition time is 15 min, and the thickness of the ZnO layer is 900 nm, so that the light-trapping structure that improves the surface of the silicon substrate can be prepared.

[0043] The technical effect of the light trapping structure is similar to that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com