Medical magnesium alloy surface mesoporous biological glass coating and preparation method

A technology of biological glass and bioactive glass, which is applied in medical science, prosthesis, surgery, etc., to achieve the effect of short production cycle, simple process and improved biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

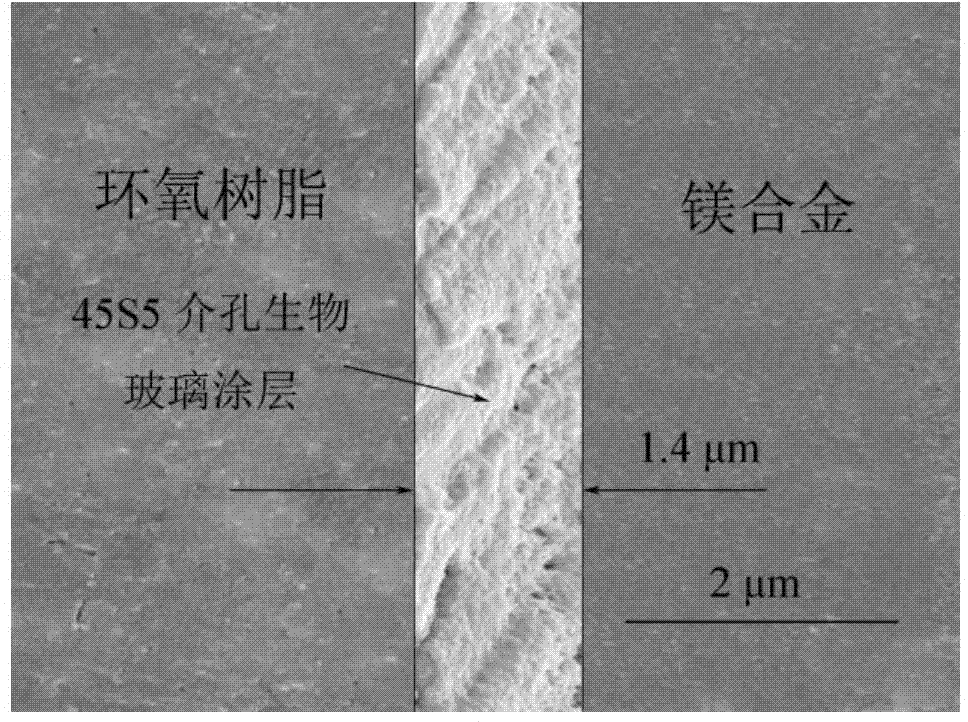

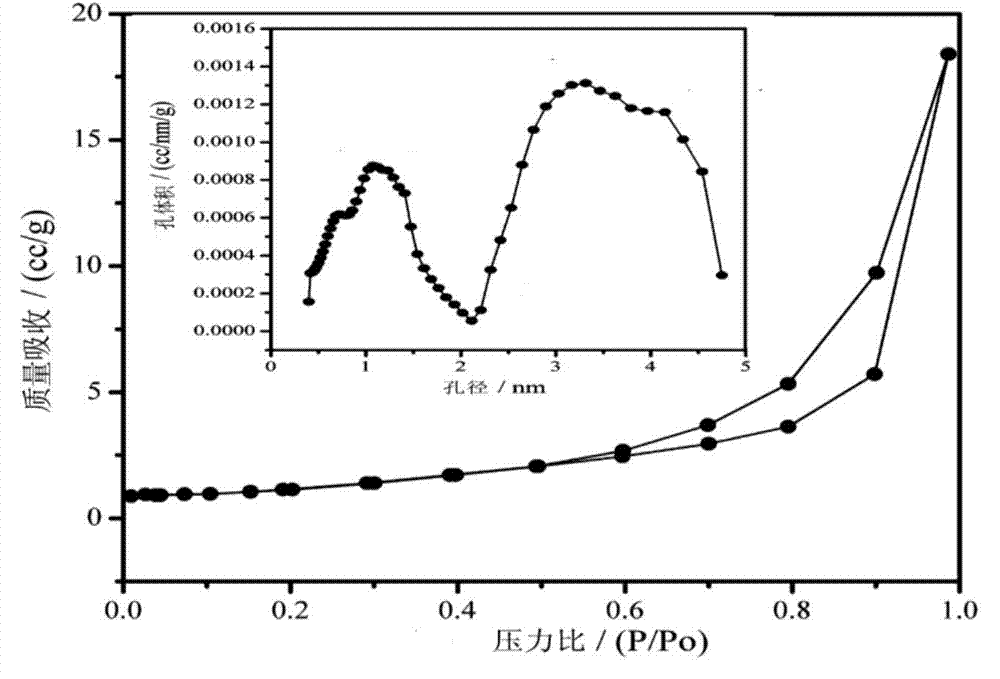

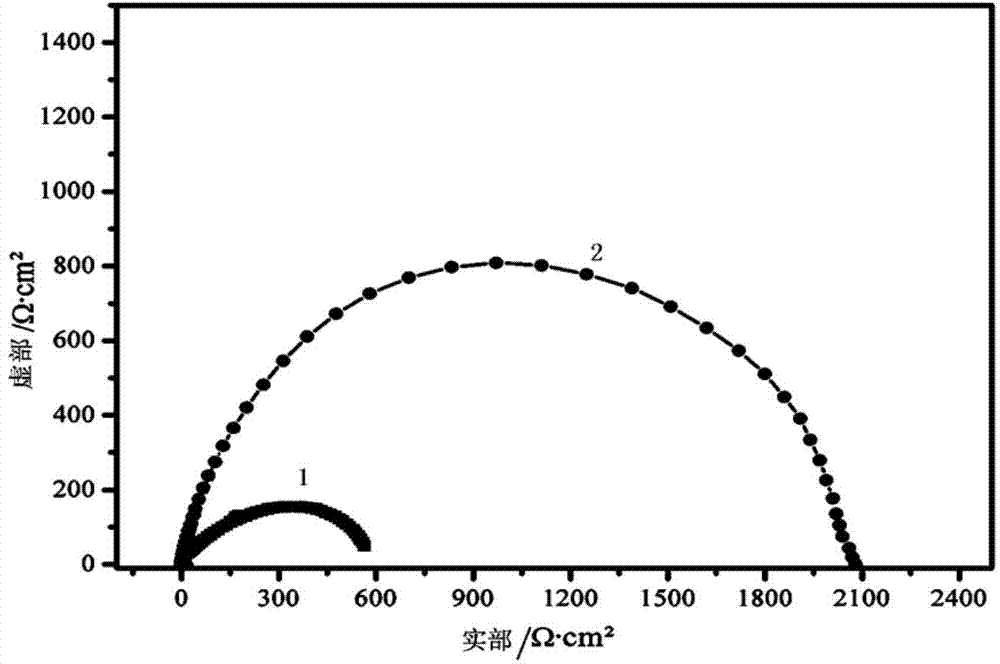

[0030] The preparation method of the mesoporous biological glass coating on the surface of medical magnesium alloy, the steps are as follows:

[0031] 1) Preparation of 45S5 bioactive glass sol system containing template

[0032] (1) According to SiO in 45S5 bioglass 2 / P 2 o 5 Weigh the ethyl orthosilicate and add it to the nitric acid solution to dissolve, stir and mix for 20-40 minutes, then add triethyl phosphate, continue stirring for 10-15 minutes, and control the temperature at 20-30°C throughout the process to obtain transparent Silicon-phosphorus-based precursor solution, wherein the molar ratio of Si / P is 46.14:5.2;

[0033] (2) According to CaO / Na in 45S5 bioglass 2 The mass ratio of O is taken by weighing soluble calcium salt and sodium salt, dissolved in deionized water to obtain calcium sodium inorganic salt solution, wherein the mol ratio of Ca / Na is 26.91:48.7;

[0034] (3) According to the critical micelle concentration value of the template agent, add th...

Embodiment 1

[0039] 1.45S5 bioactive glass sol system

[0040] With Ca(NO 3 ) 2 4H 2 O, NaNO 3 , tetraethyl orthosilicate and triethyl phosphate as raw materials, according to the Na in the 45S5 bioglass system 2 O-CaO-SiO 2 -P 2 o 5 The mass ratio is 24.5:24.5:45:6.0, and the medicines are weighed.

[0041] (1) Weigh 3.4ml tetraethyl orthosilicate (TEOS) dissolved in 2.4ml HNO with a concentration of 0.1mol / L 3 In the solution, stir and mix for 30 minutes, then add 0.29ml of triethyl phosphate (TEP), continue to stir for 15 minutes (the temperature is controlled between 20 and 30°C), and the molar ratio of Si / P is 46.14:5.2.

[0042] (2) Accurately weigh 1.38g NaNO 3 and 2.12g Ca(NO 3 ) 2 .4H 2 O, it was added to 40ml of deionized water, stirred to dissolve, the molar ratio of Ca / Na was 26.91:48.7.

[0043] (3) Weigh 3.46g of F127, slowly add it to 72ml of absolute ethanol, heat and stir (keep below 40°C) until the solution turns from cloudy to clear.

[0044] (4) According ...

Embodiment 2

[0049] 1.45S5 bioactive glass sol system

[0050] (1) Weigh 3.4ml tetraethyl orthosilicate (TEOS) dissolved in 2.4ml HNO with a concentration of 0.1mol / L 3 In the solution, stir and mix for 30 minutes, then add 0.29ml of triethyl phosphate (TEP), continue to stir for 15 minutes (keep the temperature between 20 and 30°C), and the molar ratio of Si / P is 46.14:5.2.

[0051] (2) Accurately weigh 1.38 grams of NaNO 3 and 2.12 g Ca(NO 3 ) 2 .4H 2 O, it was added to 40ml of deionized water, stirred to dissolve, the molar ratio of Ca / Na was 26.91:48.7, and the molar ratio of Ca / Na was 26.91:48.7.

[0052] (3) Weigh 0.44g of F127, slowly add it to 72ml of absolute ethanol, heat and stir (keep below 40°C) until the solution turns from turbid to clear, set aside.

[0053] (4) According to the template agent: 45S5 (Na 2 O-CaO-SiO 2 -P 2 o 5 ) with a mass ratio of 21:24.5:24.5:45:6.0 Add the ethanol solution (3) and calcium sodium salt solution (2) of the template agent F127 to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com