Method and system for removing HCN (hydrogen cyanide) in ammonium sulfate

A technology for removing ammonium sulfate, applied in a method and system field of HCN, can solve problems such as environmental pollution, environmental secondary pollution, and low cyanide content, and achieve the goals of reducing production costs, improving product quality, and reducing pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

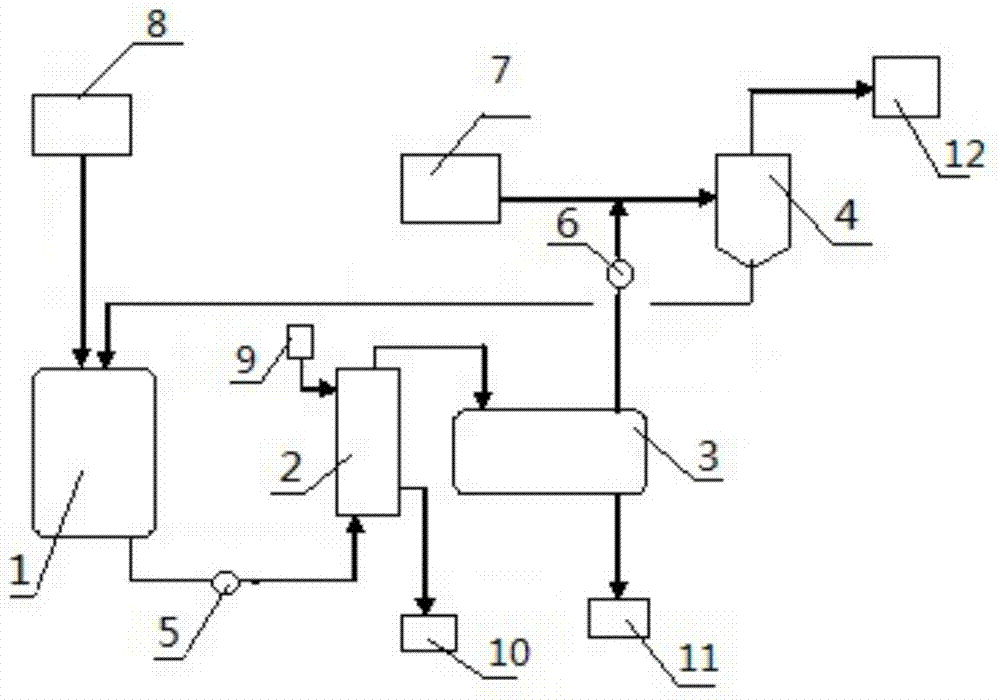

Method used

Image

Examples

Embodiment 1

[0047]Angle's method is proposed by German I.G company Androsov (L.Andrussow), and realizes a kind of method of industrialized production of hydrocyanic acid first in Germany. The method uses methane, ammonia and air as raw materials and platinum as a catalyst to produce hydrocyanic acid. At present, the Angle method is one of the main methods for the industrial production of hydrocyanic acid in foreign countries. The Angle method is mature in technology, economical and reasonable, and uses natural gas (methane) as raw material, which is rich in resources.

[0048] In this example, the 1m 3 By-product ammonium sulfate solution, the mass fraction of ammonium sulfate detected by analysis is 31%, and the CN- content is 3g / L.

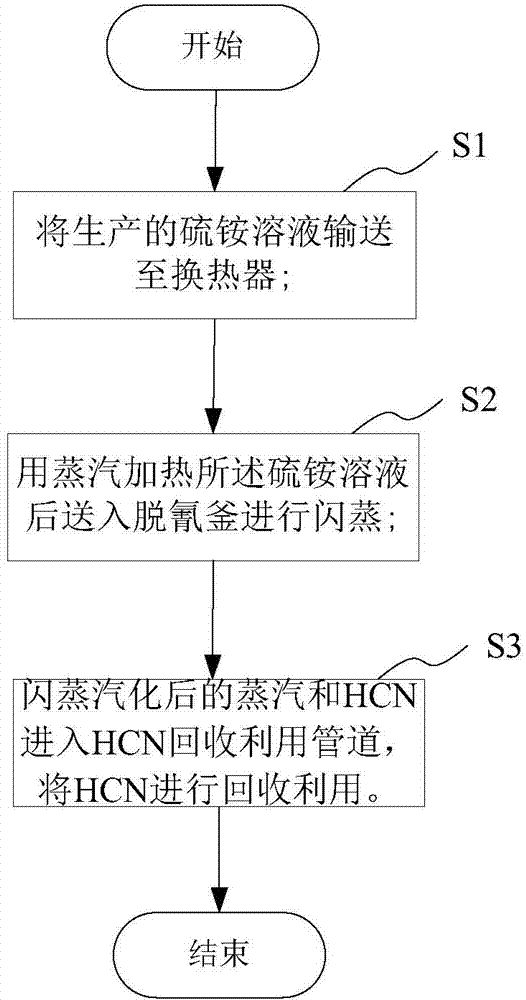

[0049] Above-mentioned solution is used the method for removing the HCN in the ammonium sulfate of the present invention, comprises the steps:

[0050] S 1 : the ammonium sulfate solution is transported to the heat exchanger with a production pump,

[0...

Embodiment 2

[0061] Angle's method is proposed by German I.G company Androsov (L.Andrussow), and realizes a kind of method of industrialized production of hydrocyanic acid first in Germany. The method uses methane, ammonia and air as raw materials and platinum as a catalyst to produce hydrocyanic acid. At present, the Angle method is one of the main methods for the industrial production of hydrocyanic acid in foreign countries. The Angle method is mature in technology, economical and reasonable, and uses natural gas (methane) as raw material, which is rich in resources.

[0062] In this example, the 1m 3 By-product ammonium sulfate solution, the mass fraction of ammonium sulfate detected by analysis is 30%, and the CN- content is 6g / L.

[0063] Above-mentioned solution is used the method for removing the HCN in the ammonium sulfate of the present invention, comprises the steps:

[0064] S 1 : the ammonium sulfate solution is transported to the heat exchanger with a production pump,

[...

Embodiment 3

[0075] The light oil cracking method uses light oil (or gasoline), liquid ammonia and caustic soda as the main raw materials, and petroleum coke particles and nitrogen as auxiliary raw materials. Firstly, light oil and liquid ammonia are gasified, mixed and preheated in the atomizer according to the proportion, and the three-phase electrode is immersed in the boiling reaction furnace where the petroleum coke particle layer is conductive and heated, and it can be cracked into hydrogen at normal pressure and high temperature. The cracking gas of cyanic acid.

[0076] In this example, the 1m obtained by using the light oil cracking method 3 By-product ammonium sulfate solution, the mass fraction of ammonium sulfate detected by analysis is 30%, and the CN- content is 6g / L.

[0077] Above-mentioned solution is used the method for removing the HCN in the ammonium sulfate of the present invention, comprises the steps:

[0078] S 1 : the ammonium sulfate solution is transported to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com