Catalyst for preparing sec-butyl acetate from carbon tetraolefin

A technology of sec-butyl acetate and carbon tetraolefin, which is used in molecular sieve catalysts, physical/chemical process catalysts, carboxylate preparation and other directions, can solve the problems of large equipment investment, high temperature resistance, and difficult separation, and reduce production costs. , long service life and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Catalyst preparation

[0028] Preparation of Catalyst A:

[0029] Mix 200 grams of HY-type zeolite, 100 grams of hydrogen-type mordenite, 70 grams of silicon oxide and 2 g of scallop powder; add an appropriate amount of 5% nitric acid after mixing, extrude into a 2mm cylindrical shape after mixing, and cut into 2- 3mm; dried at 80°C and 120°C for 10 hours respectively, then calcined at 580°C for 6 hours, taken out and cooled to room temperature, and placed in a desiccator for later use. Catalysts prepared in this way are denoted shaped catalysts. Take 100g of shaped catalysts and impregnate them with appropriate amount of 5% phosphoric acid and boric acid solutions respectively, dry them at 80°C and 120°C for 10 hours respectively, calcinate at 580°C for 6 hours, put them in a desiccator for later use. Catalyst A is obtained. Preparation of Catalyst B:

[0030] Same as Catalyst A, except that 40g of silicon oxide is added and impregnated with 10% phosphoric acid and...

Embodiment 1

[0035] Raw materials include glacial acetic acid with a purity greater than 99.5% and a composition of isobutane 44.19%, n-butane 13.23%, 1-butene 13.76%, t-2-butene 16.55%, isobutene 0.11%, c-2-butene 11.75% after ether C 4 Fraction (I).

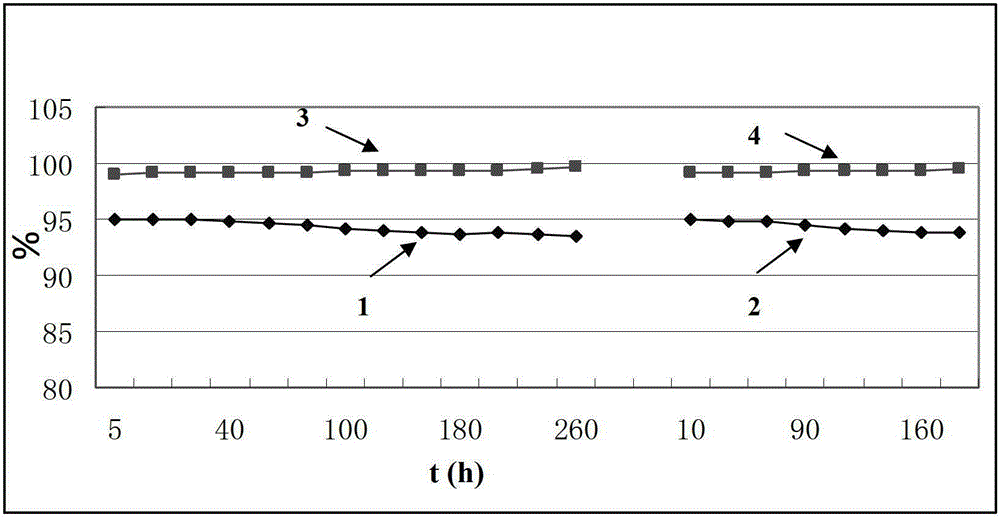

[0036] Take out 20 grams of prepared catalyst A and pack it into the reactor as a whole. Acetic acid enters from the top of the reactor with a metering pump, and after ether, C 4 The fraction enters from the bottom of the reactor through a liquid mass flow meter. The reaction results are shown in Table 2.

Embodiment 2

[0038]Raw materials include glacial acetic acid with a purity greater than 99.5% and a composition of isobutane 0.25%, n-butane 20.45%, 1-butene 5.11%, t-2-butene 43.72%, isobutene 0.12%, c-2-butene 30.17% after ether C 4 Fraction (II).

[0039] Take out 20 grams of prepared catalyst A and pack it into the reactor as a whole. Acetic acid enters from the top of the reactor with a metering pump, and after ether, C 4 The fraction enters from the bottom of the reactor through a liquid mass flow meter. The reaction results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com