Industrial wastewater treatment method and device

A technology for industrial wastewater and treatment equipment, which is applied in metallurgical wastewater treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. Cost reduction and other issues, to achieve the effect of stable membrane flux, long sewage discharge cycle, and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

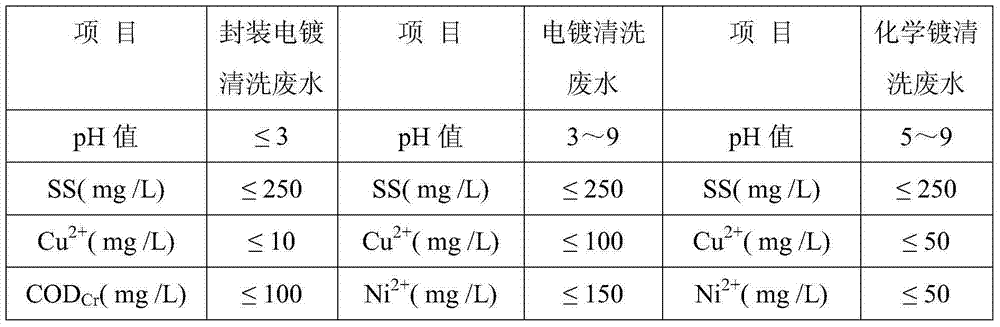

[0035]In this embodiment, the electroplating wastewater in the packaging process of a semiconductor company is used. The quality of the wastewater is as shown in Table 2, which has the characteristics of high solid content, high organic content, and heavy metal ions.

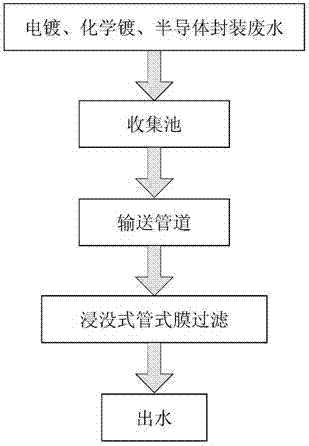

[0036] Such as figure 1 In the process flow shown, the production wastewater is collected in the collection tank of the workshop, and the wastewater is pumped into the treatment tank of the improved submerged tubular membrane treatment device, and sodium hydroxide or potassium hydroxide is added to the transportation pipeline, and then centrifugally lifted The pump is stirred to make it fully react to form a water-insoluble hydroxide precipitate, and then the reacted water is filtered by an improved submerged tubular membrane treatment device, and the water filtered by the membrane can be directly reused.

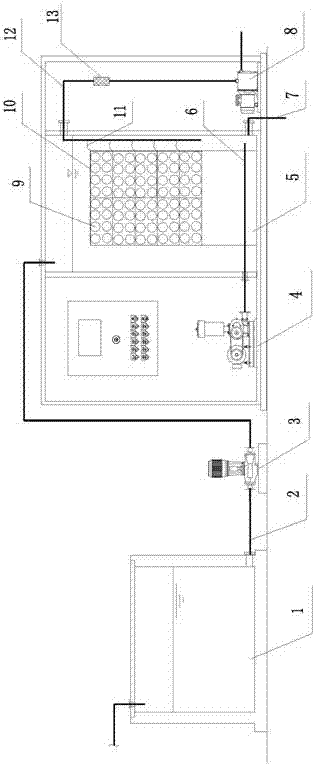

[0037] The submerged tubular membrane filtration unit adopts the submerged tubular membrane separation equ...

Embodiment 2

[0044] A specialized electroplating company electroplates copper, nickel, zinc, tin, etc. on the surface of different substrates. The water quality of the electroplating wastewater after it is discharged into the collection pool is listed in Table 3. Pump the wastewater in the collection tank into the submerged tubular membrane treatment device for treatment, add sodium hydroxide to the pipeline before entering the device, and the mixed wastewater after being stirred and mixed by the centrifugal lift pump enters the submerged tubular membrane treatment device. In the process, the tubular membrane module is used for filtration, and the quality of the filtered effluent can be directly reused. The water quality is shown in Table 3.

[0045] Table 3 The water quality of the above-mentioned electroplating wastewater and effluent after treatment

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com