Preparation method of tellurium diethyl dithiocarbamate

A technology of diethyldithiocarbamate and sodium diethyldithiocarbamate is applied in the field of preparation of rubber vulcanization accelerators, and can solve the problems of environmental and human harm, unqualified product quality, large amount of waste water and the like, Achieve the effect of avoiding harmful gases, reducing production costs and simplifying processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

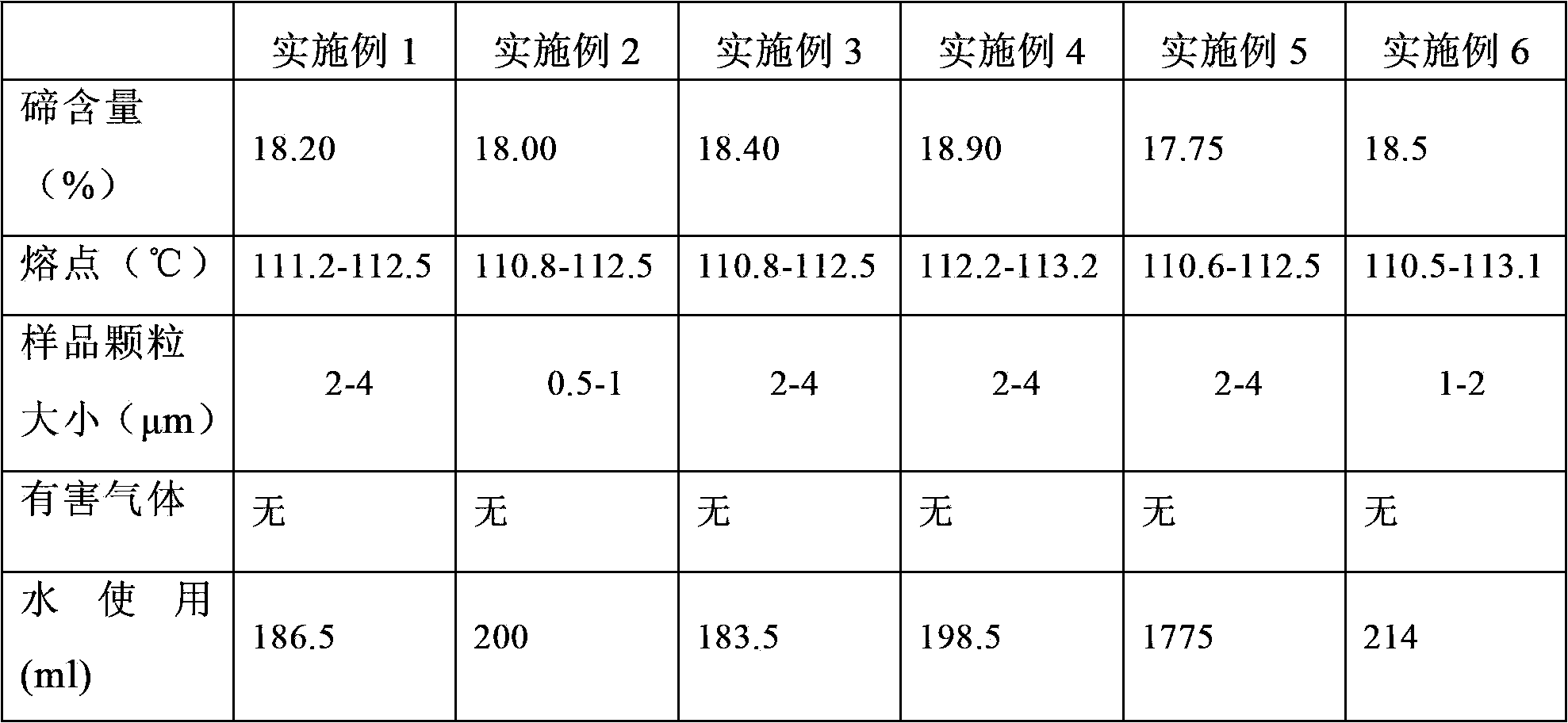

Examples

preparation example Construction

[0015] The preparation method of tellurium diethyldithiocarbamate according to the present invention comprises the steps of: heating the tellurium-containing waste with alkali to dissolve and remove impurities to obtain an alkali metal tellurite solution; Sodium formate is dissolved in the buffer solution to obtain a buffer solution containing sodium diethyldithiocarbamate; alkali metal tellurite solution and hydrochloric acid solution are added to the buffer solution containing sodium diethyldithiocarbamate, so that two Sodium ethyl dithiocarbamate reacts with alkali metal tellurite, wherein the buffer solution is one of boric acid-borax solution, borax-disodium hydrogen phosphate solution, and disodium hydrogen phosphate-sodium hydroxide solution; after the reaction is completed Aging; followed by cooling, filtration, washing and drying to obtain diethyl dithiocarbamic acid tellurium.

[0016] In the method for preparing tellurium diethyldithiocarbamate according to the pres...

Embodiment 1

[0027] Ball mill 8.25g semiconductor refrigeration waste (43% tellurium content) to 0.325mm, mix with 7.5g sodium hydroxide and 3.1g sodium carbonate in a crucible and melt to 650°C, keep the temperature for 1h; add 2.1g nitric acid in batches Sodium and stir the melt, keep warm for 1h, take out and cool, break the obtained yellow product to 0.15mm, leaching with hot water at 80°C, liquid-solid ratio (mass ratio between hot water and broken yellow product) 4:1, finally Obtain 50ml sodium tellurite solution, the analysis concentration is 0.49mol / L.

[0028] 18.5g DDTC was dissolved in 130ml borax-disodium hydrogen phosphate buffer solution (pH=9.0) in a round bottom flask, heated to a temperature of 50°C, and 31.5ml sodium tellurite solution (0.49 mol / L) and 65ml hydrochloric acid solution (1mol / L), the relative speed of dropping is 1:2 in terms of droplets (0.05ml per drop), the temperature of the reaction process is controlled at 50°C, the dropping time is 1.5h, and then Age...

Embodiment 2

[0030] 6.95g of cadmium telluride waste (53% tellurium content) was ball-milled to 0.125mm, mixed with 8.1g of potassium hydroxide and 4.6g of potassium carbonate in a crucible and melted to 640°C, kept at constant temperature for 1h; g sodium nitrate and stir the melt, keep it warm for 1h, take it out and cool, break the obtained product to 0.15mm, leaching with hot water at 100℃, liquid-solid ratio (mass ratio between hot water and broken product) 3:1, filter Finally, 50 ml of potassium tellurite solution was obtained with an analytical concentration of 0.50 mol / L.

[0031] Dissolve 18.5g of DDTC in 130ml of boric acid-borax buffer solution (pH=8.4) in a round bottom flask, heat to a temperature of 50°C, and simultaneously add 31.25ml of potassium tellurite solution (0.50mol / L) and 70ml of hydrochloric acid solution (1mol / L), the relative speed of dropping is 1:2 in terms of droplets (0.05ml per drop), the temperature of the reaction process is controlled at 50°C, the dropp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com