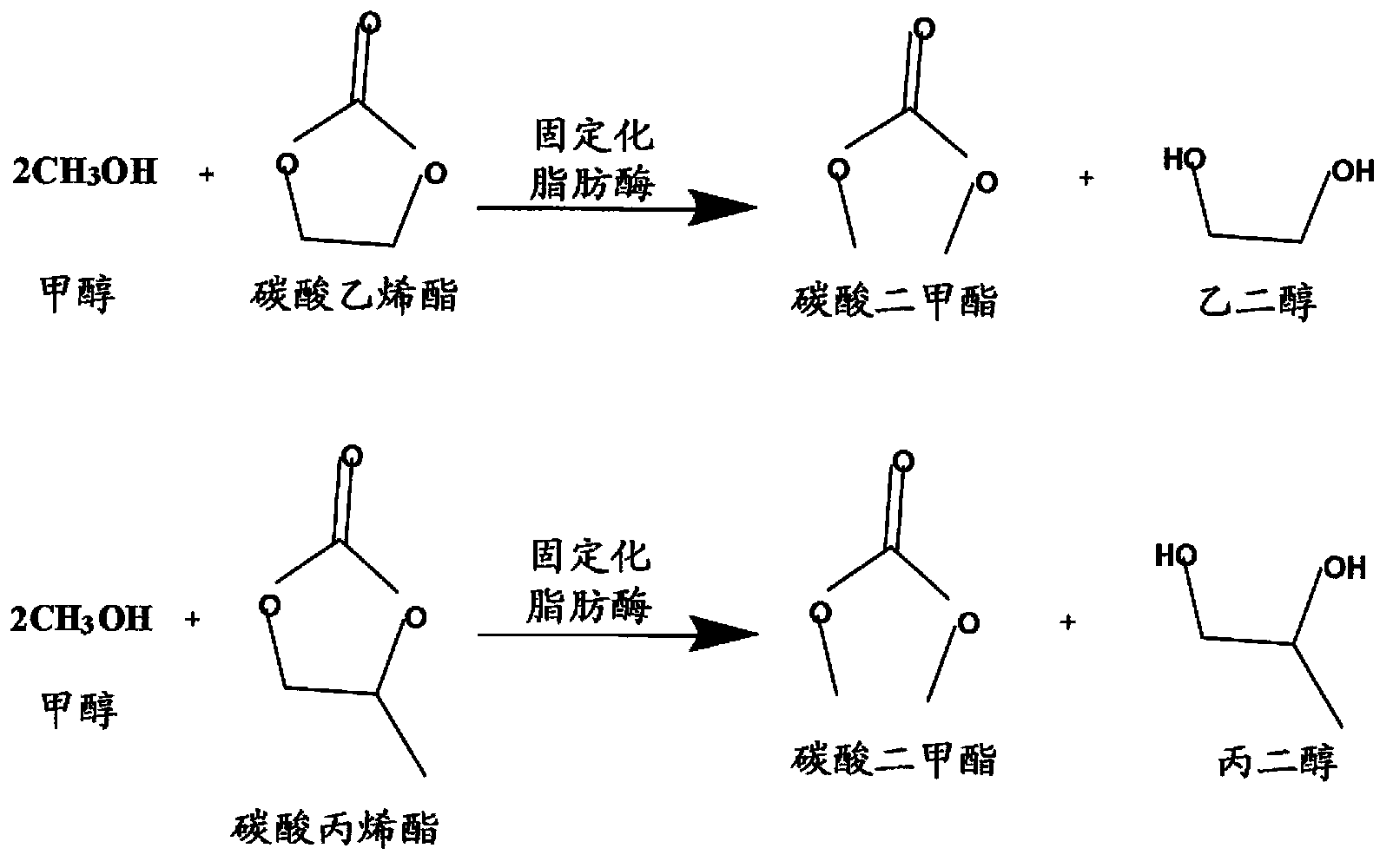

Method for preparing dimethyl carbonate by taking immobilized lipase as catalyst

A technology for immobilizing lipase and dimethyl carbonate, which is applied in the directions of immobilization on/in organic carriers, chemical industry, sustainable manufacturing/processing, etc., can solve problems such as catalyst deactivation, achieve high conversion rate, Broad application prospects and highly selective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

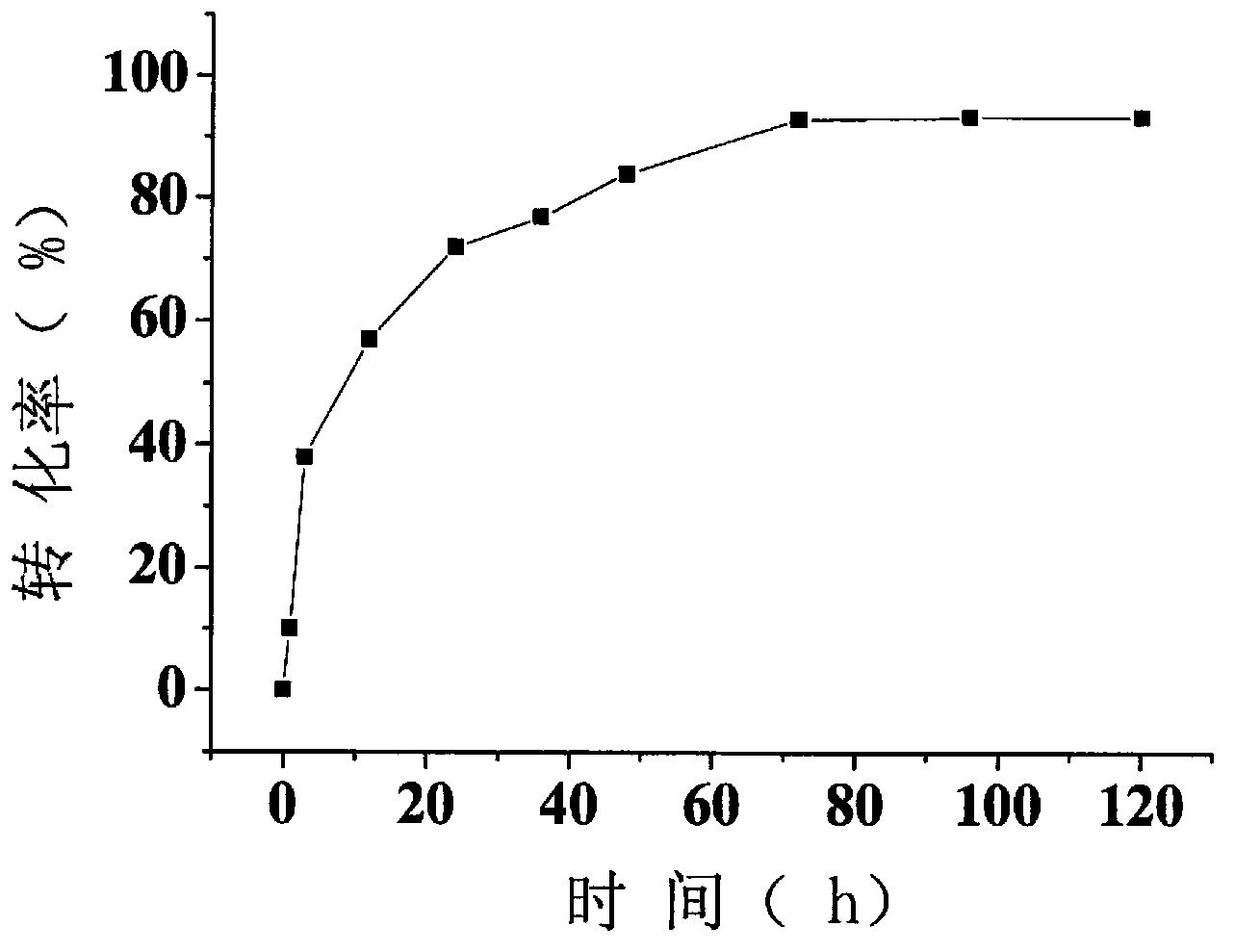

Embodiment 1

[0042] 1) Immobilize lipase with substrate:

[0043] Add 400 grams of polyvinyl alcohol and 25 liters of deionized water in sequence in a 50-liter container to form a polyvinyl alcohol solution, heat until the polyvinyl alcohol solution boils, and keep stirring during the heating process to prevent the polyvinyl alcohol from sinking to the bottom of the container If it turns yellow due to excessive heat, a small amount of deionized water can be added during the boiling process to prevent the solution from overflowing. After boiling for about 50 minutes, the polyvinyl alcohol will basically dissolve; after cooling to room temperature, stir for 60 minutes until the polyvinyl alcohol solution is basically colorless and transparent; 100 grams The mixture of Penicillium extensa lipase and 300 grams of deionized water is added to the polyvinyl alcohol solution to obtain a mixed solution, and after stirring the mixed solution for 120 minutes, the mixed solution is evenly introduced in...

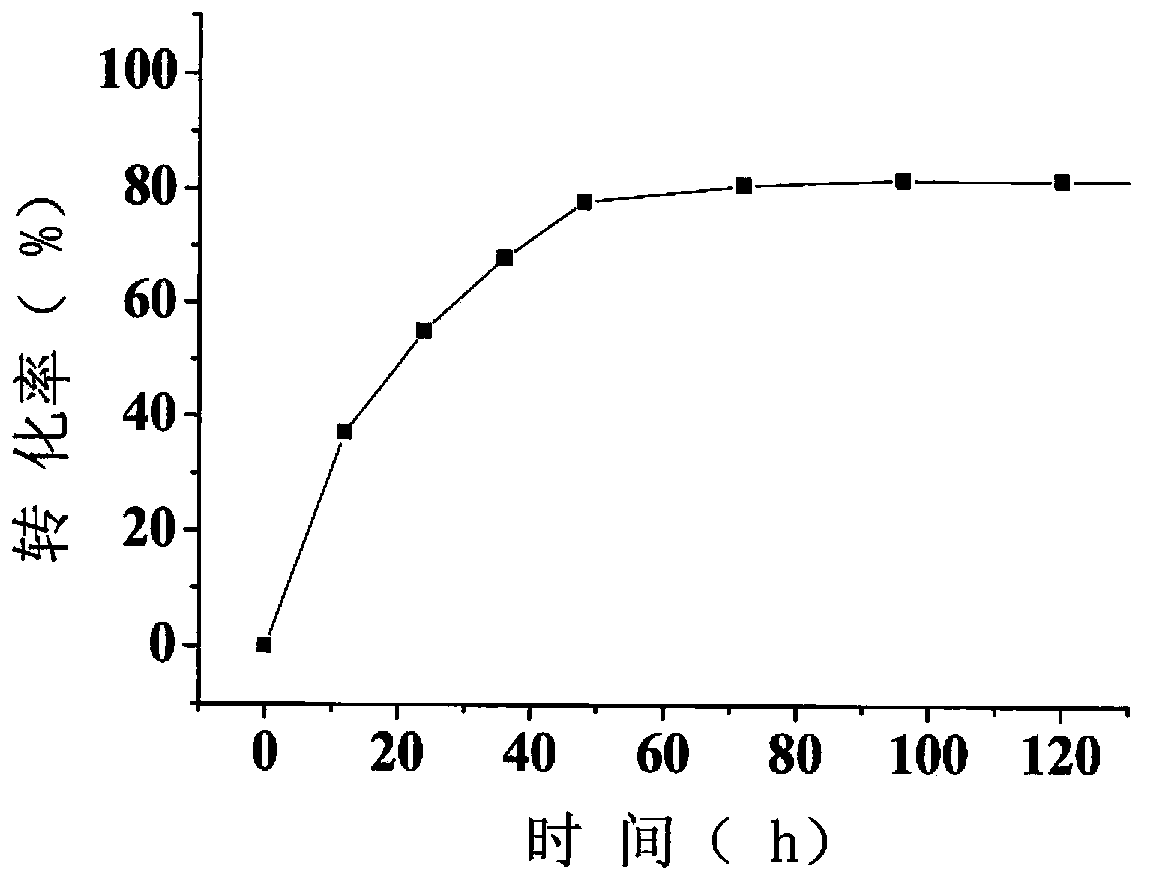

Embodiment 2

[0048] 1) Immobilize lipase with substrate:

[0049] Add 400 grams of hydroxypropyl methylcellulose and 25 liters of deionized water in sequence in a 50-liter container to form a hydroxypropyl methylcellulose solution, and heat until the hydroxypropyl methylcellulose solution boils. Stir continuously to prevent the hydroxypropyl methylcellulose from sinking into the bottom of the container and turn yellow due to excessive heat. During the boiling process, a small amount of deionized water can be added to prevent the solution from overflowing. After boiling for about 50 minutes, the hydroxypropyl methylcellulose is basically dissolved After being cooled to room temperature, stir for 60 minutes until the hydroxypropyl methylcellulose solution is basically colorless and transparent; the mixture of 100 grams of Penicillium extensa lipase and 300 grams of deionized water is added to the hydroxypropyl methylcellulose solution to obtain A mixed solution, after stirring the mixed solu...

Embodiment 3

[0054] 1) Immobilize lipase with substrate:

[0055] Add 400 grams of matrix (the mass ratio of polyvinyl alcohol in the matrix to sodium hydroxymethyl cellulose is 1:1) and 25 liters of deionized water successively in a 50-liter container to form a matrix solution, and heat until the matrix solution boils , Stir constantly during the heating process to prevent the substrate from sinking into the bottom of the container and turn yellow due to excessive heating. During the boiling process, a small amount of deionized water can be added to prevent the solution from overflowing. After boiling for about 50 minutes, the substrate basically dissolves; after cooling to room temperature, stir for 60 minutes Until the matrix solution is basically colorless and transparent; a mixture of 100 grams of Penicillium extensa lipase and 300 grams of deionized water is added to the matrix solution to obtain a mixed solution, and the mixed solution is evenly introduced after stirring the mixed so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com