A method for separating and extracting L-serine from Corynebacterium glutamicum fermentation broth

A technology of Corynebacterium glutamicum and fermentation broth, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as separation difficulties, achieve high extraction efficiency, be beneficial to comprehensive utilization, and be easy to realize in industrialization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Flocculation: Take 50 L of Corynebacterium glutamicum fermentation broth, adjust the pH of the fermentation broth to 3.0 with hydrochloric acid, and the liquid temperature is 30°C, add 0.5 L of 20g / L polyacrylamide solution, stir for 40 minutes, let it stand for one hour, and then centrifuge. The precipitate was removed to obtain 47.5L of supernatant. After testing, the removal rate of bacteria by polyacrylamide flocculation was 98.49%;

[0055] Decolorization: Add 0.5 kg of powdered activated carbon to the above liquid, heat up to 60°C, stir for 30 minutes to decolorize, filter to remove the activated carbon, and obtain 46L of decolorized liquid. After testing, the decolorization rate of activated carbon is 92.73%. Through flocculation and decolorization operations, L- The yield of serine is 90.2%;

[0056] Ultrafiltration: Roll-type ultrafiltration membrane test device (PVDF membrane, filtration area 0.5m 2 ) Perform ultrafiltration on the obtained 46L decolori...

Embodiment 2

[0062] flocculation : Take 50 L of Corynebacterium glutamicum fermentation broth, adjust the pH of the fermentation broth to 5.0 with hydrochloric acid, and adjust the liquid temperature to 40°C, add polyacrylamide to adjust its concentration to 150 mg / L, stir for 60 minutes, and centrifuge after standing for 3 hours , remove the precipitate to obtain the clear liquid;

[0063] bleaching : Add powdered activated carbon to the above clear liquid in an amount of 20g / L, heat up to 50°C, stir and decolorize for 60min, filter and remove the activated carbon to obtain a decolorized solution;

[0064] ultrafiltration : The roll-type ultrafiltration membrane test device is used to carry out ultrafiltration on the decolorization liquid, and its molecular weight cut-off is 5000Da. When the remaining 5-8L of the decolorization liquid to be intercepted is left, add 5-10L of purified water to wash, wash for 3 times, and combine Obtain ultrafiltrate;

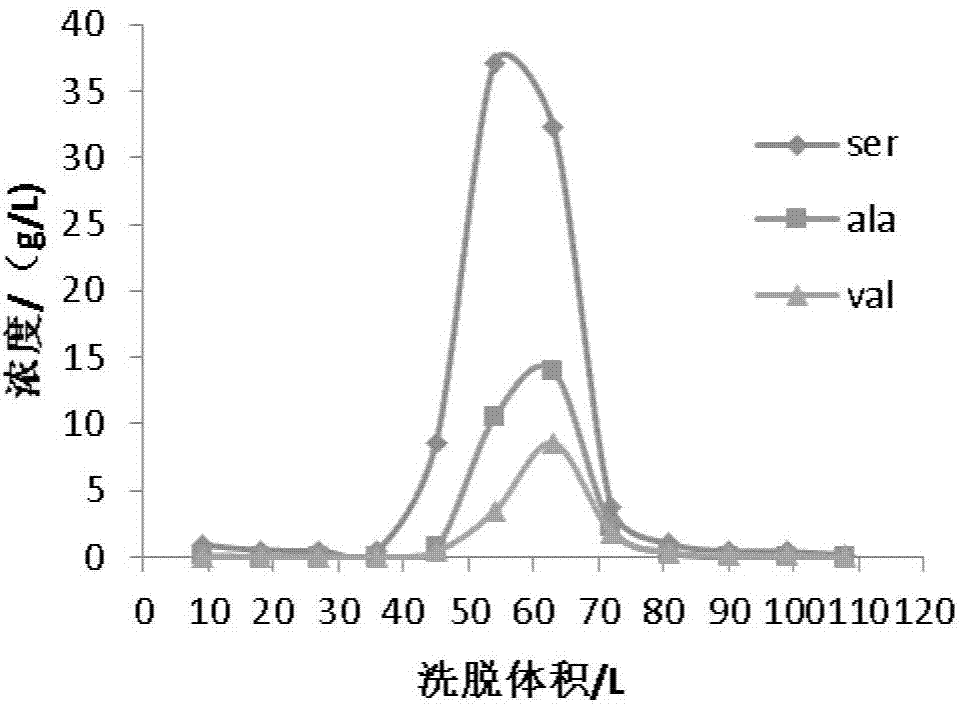

[0065] Adsorption and Elution...

Embodiment 3

[0070] flocculation : Take 50 L of Corynebacterium glutamicum fermentation broth, adjust the pH of the fermentation broth to 4.0 with hydrochloric acid, and adjust the liquid temperature to 30°C, add polyacrylamide to adjust its concentration to 10 mg / L, stir for 90 minutes, and centrifuge after standing for 6 hours , remove the precipitate to obtain the clear liquid;

[0071] bleaching : Add powdered activated carbon to the above clear liquid in an amount of 5g / L, heat up to 65°C, stir for 60 minutes to decolorize, filter to remove the activated carbon, and obtain a decolorized solution;

[0072] ultrafiltration : Ceramic ultrafiltration membrane test device is used to carry out ultrafiltration on the decolorization liquid, and its molecular weight cut-off is 2000Da. When the remaining 5-8L of the decolorization liquid to be intercepted is left, 5-10 L of purified water is added to wash, and the washing operation is performed 3 times, and combined to obtain ultrafiltrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com