Method for treating reverse osmosis concentrated solution by using singlet oxygen produced from peroxymonosulfate under induction of inorganic solid peroxide

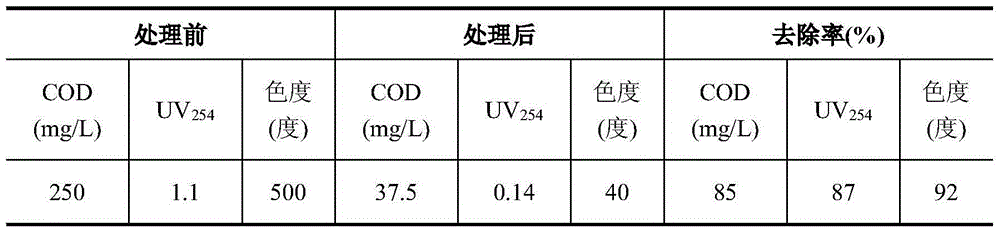

A technology of reverse osmosis concentrate and peroxide, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of complex process operation, short survival time, large instantaneous production volume, etc., and achieve good decontamination effect and high decontamination efficiency , easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

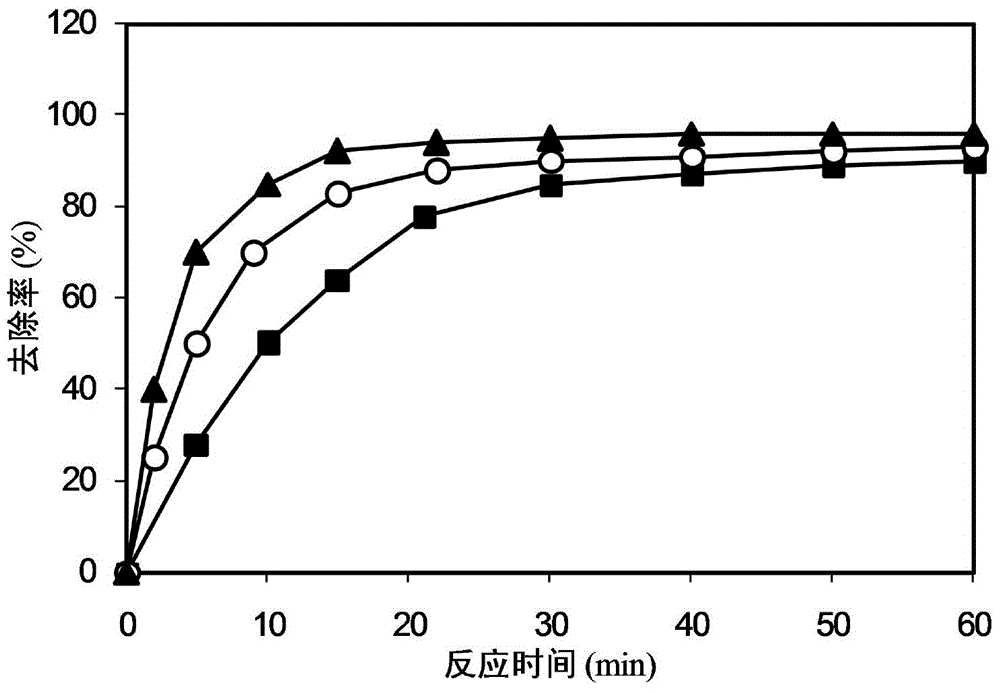

[0016] Embodiment 1: This embodiment is a method of using inorganic solid peroxide to induce persulfate to generate singlet oxygen to treat reverse osmosis concentrate, which is realized by the following steps: combining inorganic solid peroxide and peroxide Monosulfate is added to the reverse osmosis concentrate according to the mass ratio of 1:(0.5~5), stirred, and the concentration of peroxysulfate is controlled to 100~5000mg / L, and the hydraulic retention reaction is 5~60min, that is, the utilization of inorganic Solid peroxide induces singlet oxygen generation from peroxymonosulfate to treat reverse osmosis concentrate.

[0017] The inorganic solid peroxide and persulfate in this embodiment are stored separately before use.

[0018] The inorganic solid peroxide and peroxymonosulfate described in this embodiment can be made into powder reagents according to the mass ratio of 1:(0.5-5) and added together or added separately, which is the dry-type addition method; The inorg...

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the inorganic solid peroxide is sodium peroxide (Na 2 o 2 ), calcium peroxide (CaO 2 ), magnesium peroxide (MgO 2 ), barium peroxide (BaO 2 ), sodium percarbonate (Na 2 CO 4 ), potassium percarbonate (K 2 CO 4 ) in one or several mixtures in any ratio. Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: this embodiment is different from specific embodiment one or two: permonosulfate is sodium peroxosulfate (NaHSO 5 ), potassium persulfate (KHSO 5 ), ammonium persulfate (NH 4 HSO 5 ), calcium persulfate (Ca(HSO 5 ) 2 ), magnesium persulfate (Mg(HSO 5 )2 ) in one or several mixtures in any ratio. Other parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com