Preparation method of ionic type negative photosensitive polyimide material

A photosensitive polyimide and ion-type technology, applied in the field of polyimide materials, can solve the problems of difficult molecular weight control, troublesome semiconductor process application, cumbersome steps, etc., and achieve highly controllable production process, high yield, and reaction The effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

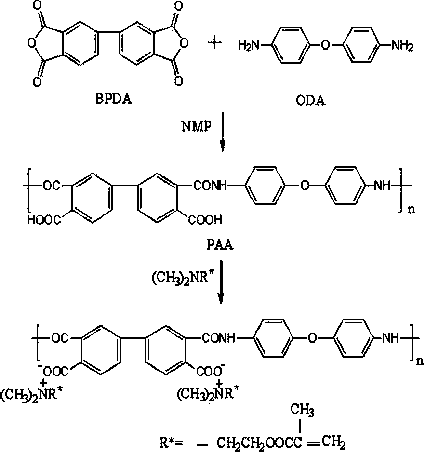

[0039] Embodiment 1 Preparation method of the present invention (1)

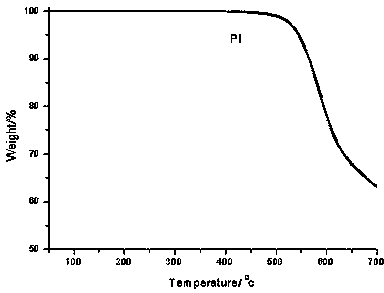

[0040] At room temperature, add a certain amount of solvent 1-methyl-2-pyrrolidone (NMP) into a 250 mL three-necked flask, and blow nitrogen gas for half an hour to remove oxygen in the flask. Using the positive addition method, accurately weigh 2g (0.01mol) of 4,4’-diaminodiphenyl ether (ODA) into a three-necked flask, and stir for 20 minutes until completely dissolved. Then accurately weighed 3.087g (0.0105mol) of 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA) into the three-necked flask in batches, and mechanically stirred for 8 hours to obtain polyimide (PI) precursor—polyamic acid (polyamide acid, PAA) solution. During the whole preparation process, a certain amount of NMP was added in good time to keep the solid content at 15%.

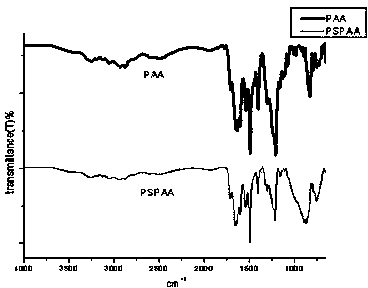

[0041] Weigh 3.297g (0.021mol) of 2-(dimethylamino)ethyl methacrylate, add it into the light yellow viscous PAA solution under the condition of avoiding light, conti...

Embodiment 2

[0047] At room temperature, add a certain amount of solvent N,N-dimethylformamide (DMF) into a 250mL three-necked flask, and blow nitrogen gas for half an hour to remove oxygen in the flask. Using the positive addition method, accurately weigh 2g (0.01mol) of 4,4’-diaminodiphenyl ether (ODA) into a three-necked flask, and stir for 20 minutes until completely dissolved. Then, accurately weighed 2.289g (0.0105mol) of pyromellitic anhydride (PMDA) was added to the three-necked flask in batches, and mechanically stirred for 8 hours to obtain the precursor of polyimide (PI) - polyamic acid (PAA ) solution. During the whole preparation process, a certain amount of DMF was added in time to keep the solid content at 15%.

[0048] Weigh 3.297g (0.021mol) of 2-(dimethylamino)ethyl methacrylate, add it into the light yellow viscous PAA solution under the condition of avoiding light, continue to stir the reaction for 5 hours, and dissolve in DMF The ionic negative photosensitive polyimi...

Embodiment 3

[0052] At room temperature, add a certain amount of solvent N,N-dimethylacetamide (DMAc) into a 250mL three-necked flask, and blow nitrogen gas for half an hour to remove oxygen in the flask. Using the positive addition method, accurately weigh 2g (0.01mol) of 4,4’-diaminodiphenyl ether (ODA) into a three-necked flask, and stir for 20 minutes until completely dissolved. Then accurately weighed 3.255g (0.0105mol) of 4,4'-oxydiphthalic anhydride (ODPA) into the three-necked flask in batches, and mechanically stirred for 8 hours to obtain the precursor of polyimide (PI) Body - polyamic acid (PAA) solution. During the whole preparation process, a certain amount of DMAc was added in time to keep the solid content at 10%.

[0053] Weigh 3.003g (0.021mol) of 2-(dimethylamino)ethyl acrylate, add it into the light yellow viscous PAA solution under the condition of avoiding light, continue to stir the reaction for 5 hours, and dissolve it in the DMAc solution The yield of ionic photos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com