Ferroferric oxide @ silicon dioxide magnetic single-hole hollow microsphere and preparation method thereof

A technology of fe3o4 and microspheres, which is applied in the direction of microsphere preparation, microcapsule preparation, and magnetic properties of inorganic materials. It can solve the problems of not using high loading capacity, etc., and achieve good chemical stability, good stability, and uniform size of microspheres Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

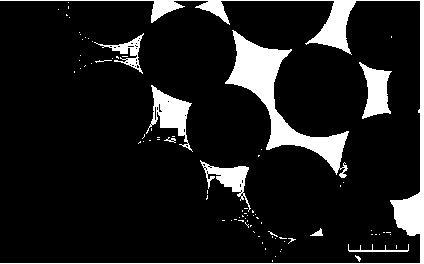

[0022] Fe 3 o 4 The preparation of nanoparticles adopts the following method: 8.1g FeCl 3 ·6H 2 O and 4.17 g FeSO 4 ·7H 2 O was dissolved in 90 mL of ultra-pure water to form a solution, heated to 55 °C after 30 min of nitrogen gas and kept at a constant temperature, and 50 mL of sodium hydroxide solution (3.0 mol / L) was added dropwise. After the sodium hydroxide solution is added dropwise, adjust the temperature to 65°C, and react at a constant temperature for one hour under a nitrogen atmosphere, then raise the temperature to 90°C, react at a constant temperature for 30 minutes, and finally turn off the heating and cool to room temperature. Separation of Fe using a magnet 3 o 4 Crystal, after the precipitation is complete, pour out the supernatant, and prepare the obtained Fe 3 o 4 transferred to a beaker, washed several times with pure water, and then washed with absolute ethanol, the obtained Fe 3 o 4 The muddy solid was vacuum dried to obtain Fe 3 o 4 Nanopart...

Embodiment 2

[0027] Fe 3 o 4 Preparation of nanoparticles and Fe 3 o 4 The surface modification of nanoparticles adopts the method in Example 1.

[0028] Adopt the method of embodiment 1 to configure DTS-Fe 3 o 4 / THF solution, and adjust its concentration to 1.0g / L.

[0029] Take 0.1mL DTS-Fe 3 o 4 / THF solution was mixed with 0.5mL of polystyrene (PS) THF solution (12.5g / L), and then 3.4mL of THF, 0.1mL of TEOS and 4mL of MeCN were added sequentially, and the mixture was mixed evenly, Quickly add 30mL water, then add CTAB / H 2 O (0.2 mL, 0.01 mol / L), mix well, add 0.5mL ammonia water, and let it stand for one day. Centrifuge to separate the precipitate, then add THF to dissolve the polymer, and finally centrifuge again to obtain Fe 3 o 4 SiO 2 Magnetic single-hole hollow microspheres. Get Fe 3 o 4 SiO 2 The scanning electron micrograph of the magnetic single-hole hollow microsphere is similar to Example 1. The average particle size of the microspheres is 302±65 nm. SiO ...

Embodiment 3

[0031] Fe 3 o 4 Preparation of nanoparticles and Fe 3 o 4 The surface modification of nanoparticles adopts the method in Example 1.

[0032] Adopt the method of embodiment 1 to configure DTS-Fe 3 o 4 / THF solution, and adjust its concentration to 1.0g / L.

[0033] Take 0.5mL DTS-Fe 3 o 4 / THF solution was mixed with 0.25 mL of polystyrene (PS) THF solution (12.5 g / L) and 0.25 mL of polymethyl methacrylate (PMMA) THF solution (12.5 g / L), and then added sequentially 3mL of THF, 0.1mL of TEOS and 4mL of MeCN, after mixing the mixture evenly, quickly add 30mL of water, then add CTAB / H 2 O (0.2 mL, 0.01 mol / L), mix well, add 0.5mL ammonia water, and let it stand for one day. Centrifuge to separate the precipitate, then add THF to dissolve the polymer, and finally centrifuge again to obtain Fe 3 o 4 SiO 2 Magnetic single-hole hollow microspheres. Get Fe 3 o 4 SiO 2 The scanning electron micrograph of the magnetic single-hole hollow microsphere is similar to Example 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com