Method for preparing self-sustained silicon nanowire array

A silicon nanowire array and metal mesh technology, applied in the field of nanomaterials, can solve the problem of not obtaining a two-dimensional silicon nanowire array, and achieve the effect of cheap raw materials, rapid preparation, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

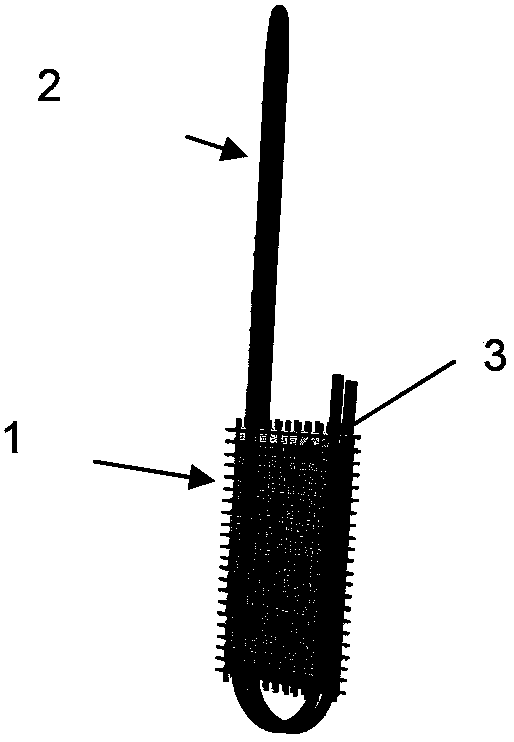

[0037] (a) JGS3 optical quartz plate with a size of 20x10x0.5mm. Two pieces of 20x10mm 20-mesh metal nickel mesh are used as current collectors, clamped and fixed with metal molybdenum wires with a diameter of 1mm to make working electrodes.

[0038] (b) CaCl at 850 °C in a molten salt electrochemical device under an argon atmosphere 2 In the molten salt, 1.9V voltage is used for electrodeoxidation, and the graphite crucible is used as the counter electrode, and the reaction time is about 5h.

[0039] (c) After the reaction is completed, remove the working electrode from the salt solution, cool it under an inert atmosphere, take it out and wash it in water, and strip off the nickel mesh, molybdenum wire and outer impurities, and the obtained product is a silicon nanowire array.

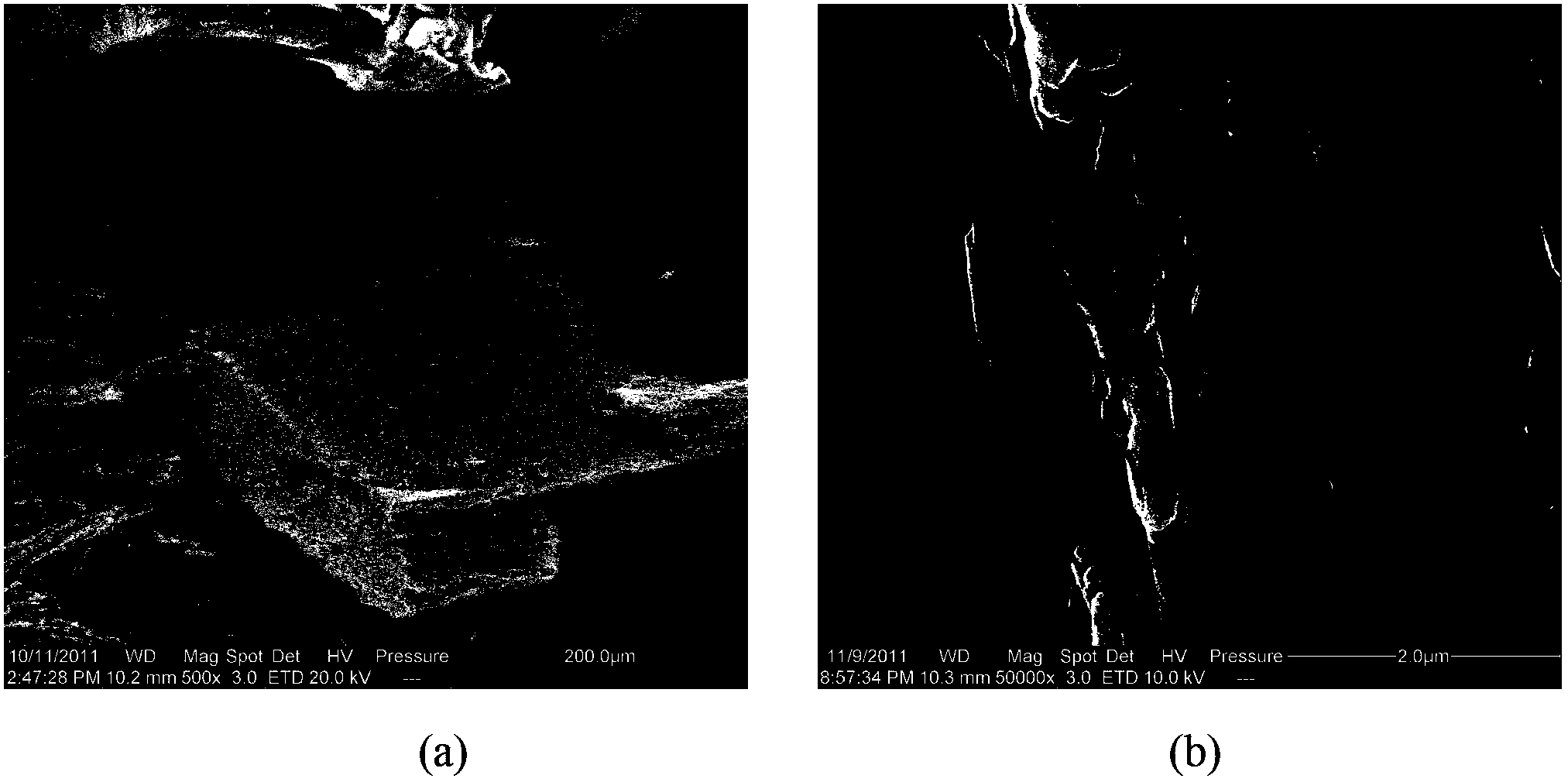

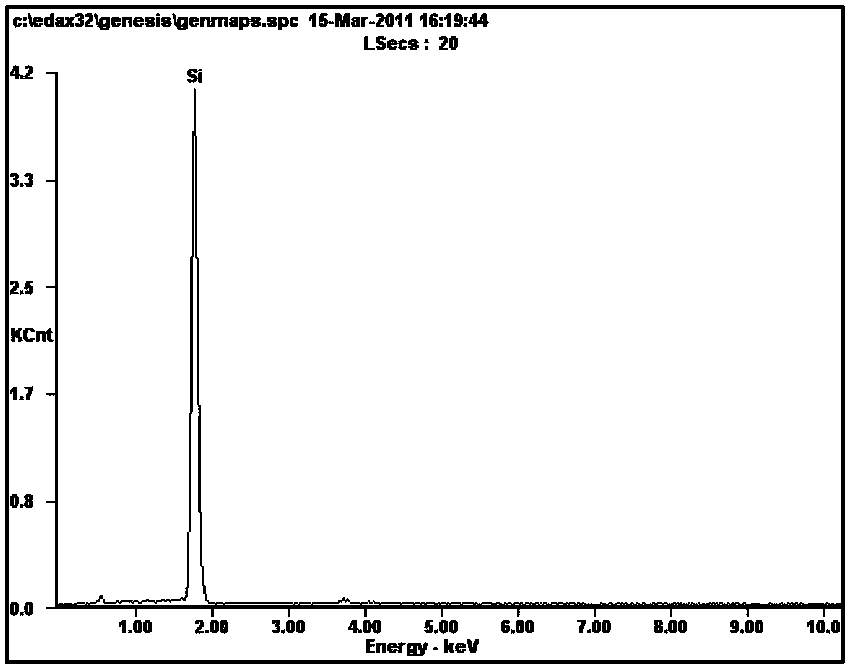

[0040] The silicon nanowire array has two layers, each layer has a thickness of about 200 microns, an area of up to 20x10mm, a relatively uniform structure, and a wire diameter of about 200 nanomete...

Embodiment 2

[0042] Same as Example 1, except that JGS1 grade optical quartz plate is used instead of JGS3 grade optical quartz plate in step (a). The synthesized nanowire arrays are denoted by NW-B.

Embodiment 3

[0044] Same as Example 1, except that in step (a) an opaque quartz plate is used instead of a JGS3 grade optical quartz plate. The synthesized nanowire arrays are denoted by NW-C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com