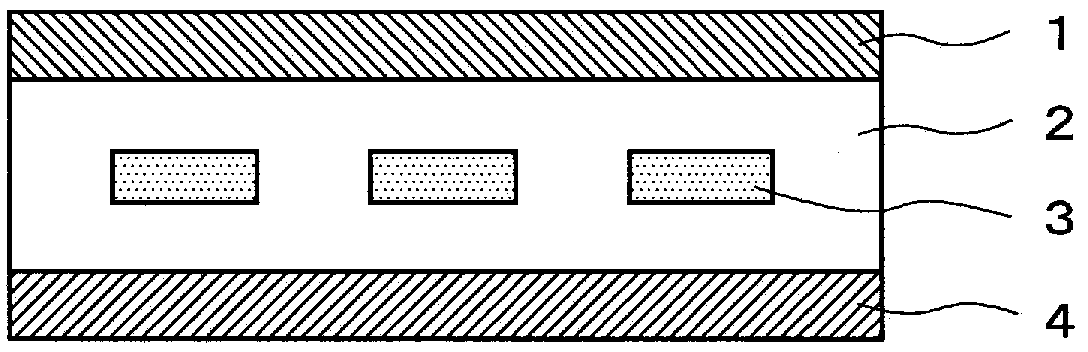

Polyvinylidene fluoride resin film, multilayer film, backsheet for solar cell module, and film manufacturing process

A technology of vinyl difluoride and its manufacturing method, which can be applied in the direction of chemical instruments and methods, synthetic resin layered products, circuits, etc., and can solve the problems of aesthetic damage, reduction of sunlight reflection efficiency, peeling strength of PVDF film and PET film, and durability of bonding sexual insufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

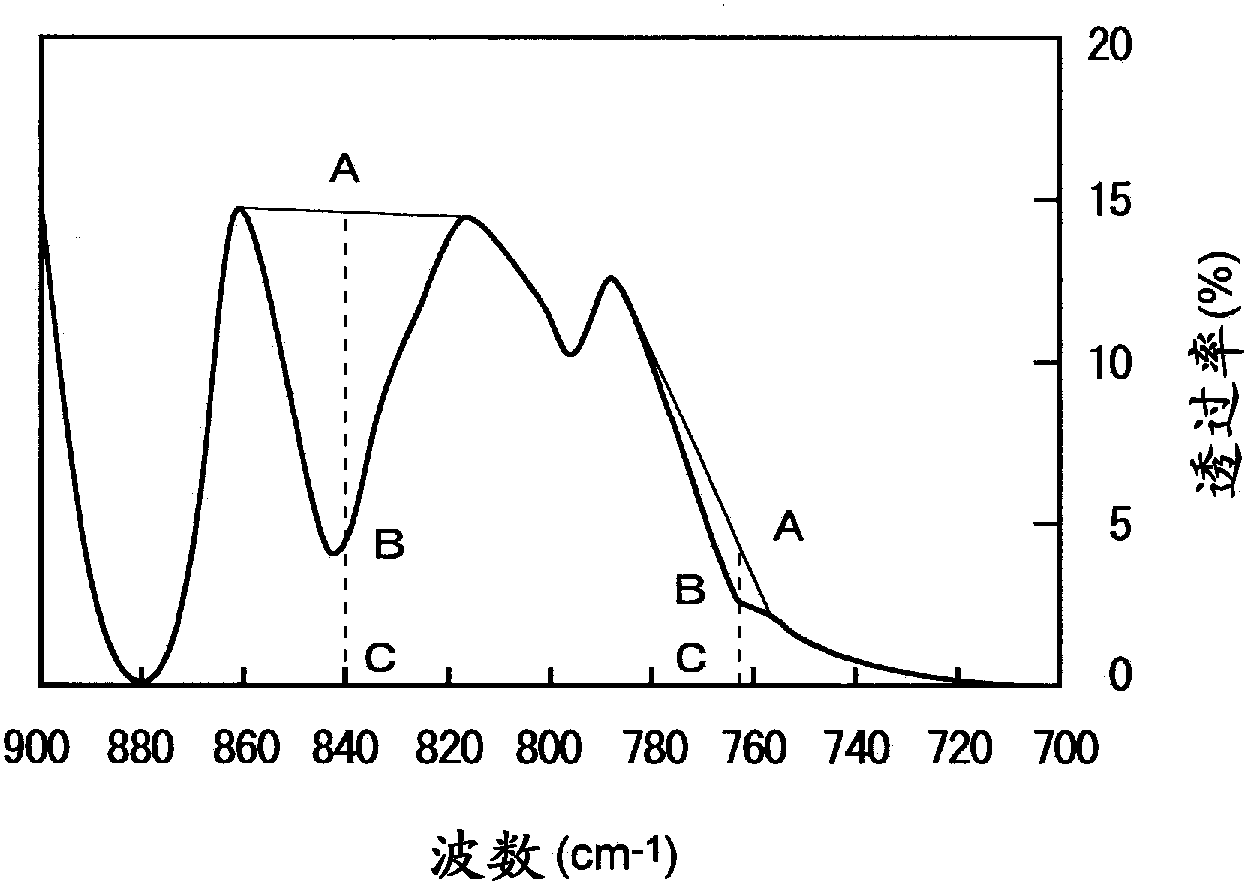

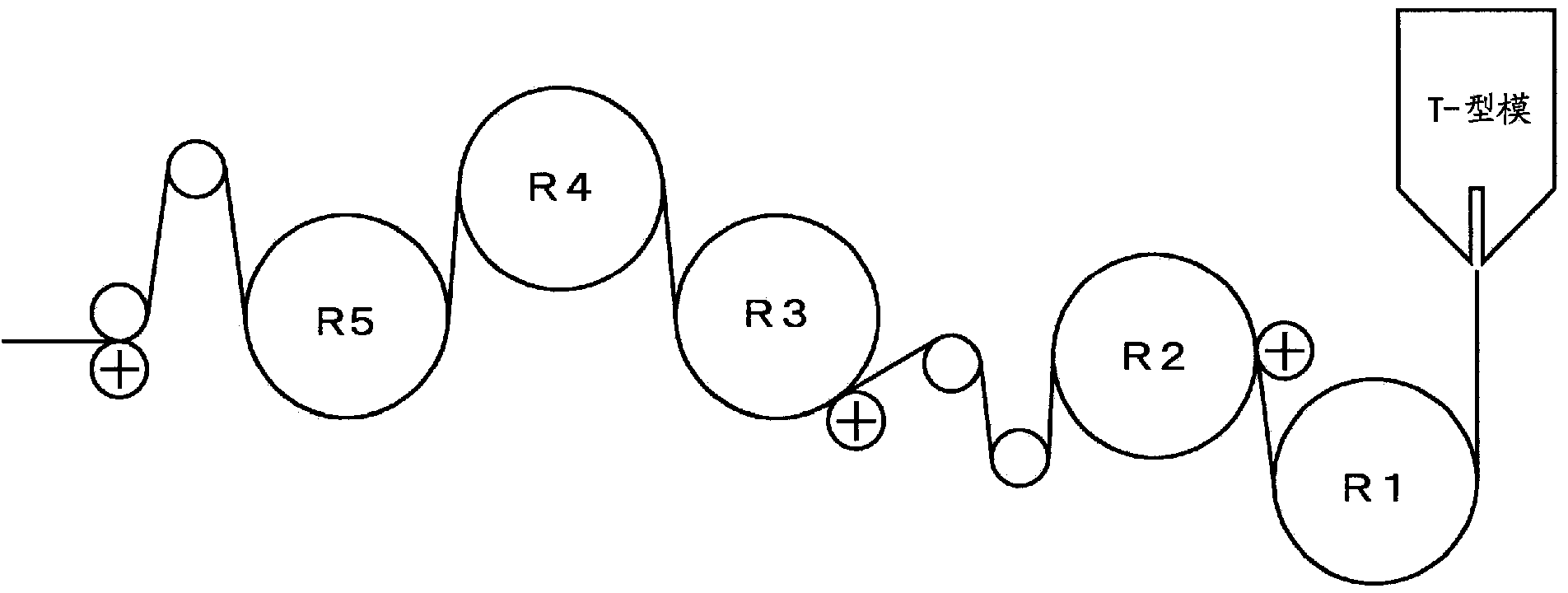

[0086] The present invention is characterized in that the PVDF film has a PVDF film in which the proportion of β-type crystals is 10% or more when the crystal structure obtained from the absorbance of infrared absorption spectrum is 100% of the total of α-type crystals and β-type crystals, It can be manufactured by strictly controlling the manufacturing conditions using a known PVDF membrane manufacturing method. Production can be carried out by, for example, dissolving or dispersing a raw material mixture (hereinafter also simply referred to as "PVDF") as a composition containing PVDF in an organic solvent, coating it on a substrate, and then using The casting method of solvent volatilization and removal; the method of vacuum evaporation PVDF powder on the substrate; the method of melting and kneading PVDF at a temperature above the melting point, and then rolling between rolls to form a film; PVDF at the melting point Melting and kneading at the above temperature, and then e...

Embodiment 1

[0130] Supply PVDF [Co., Ltd. Kureha KF (registered trademark) # 850], 100 parts by mass to the twin-screw extruder, and supply titanium oxide [TI-PURE (registered trademark) R101 manufactured by Dupon Corporation; rutile type titanium oxide, Average particle size: 0.29 μm, surface-treated product] 55.6 parts by mass, PMMA [Del Pounder (registered trademark) 70H manufactured by Asahi Kasei Chemicals Co., Ltd.] 23.4 parts by mass, acrylic elastomer [Pararoid (registered trademark) EXL manufactured by Rom & Haers Co., Ltd.] 2315] 2.5 parts by mass, calcium carbonate [SL2500 manufactured by Takehara Chemical Industry Co., Ltd.] 2.8 parts by mass, calcium stearate [manufactured by Nitto Kasei Co., Ltd.] 0.9 parts by mass, and carbon black [denka black produced by Denki Kagaku Kogyo Co., Ltd. ( Registered trademark)] 0.04 parts by mass, melted and kneaded at a temperature of 220° C., melted and extruded from the die in the form of strands, and cut after cooling to obtain pellets for...

Embodiment 2

[0133] Except having changed the surface temperature of the 1st casting roll into 50 degreeC, it carried out similarly to Example 1, and obtained the PVDF film of thickness 20 micrometers. Table 1 shows the measurement results of the ratio of β-type crystals and mechanical properties of the obtained PVDF film, and the results of thermal wrinkle evaluation during lamination bonding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com