Technology for performing high-temperature oxygen deficit treatment on hardwoods for obtaining artificial functional rosewood

A technology of high-temperature treatment and hard miscellaneous wood, which is applied in wood treatment, wood treatment details, wood processing equipment, etc., can solve the problems of lack of real wood feeling and not being real enough, and achieve the effect of realistic appearance, low production cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

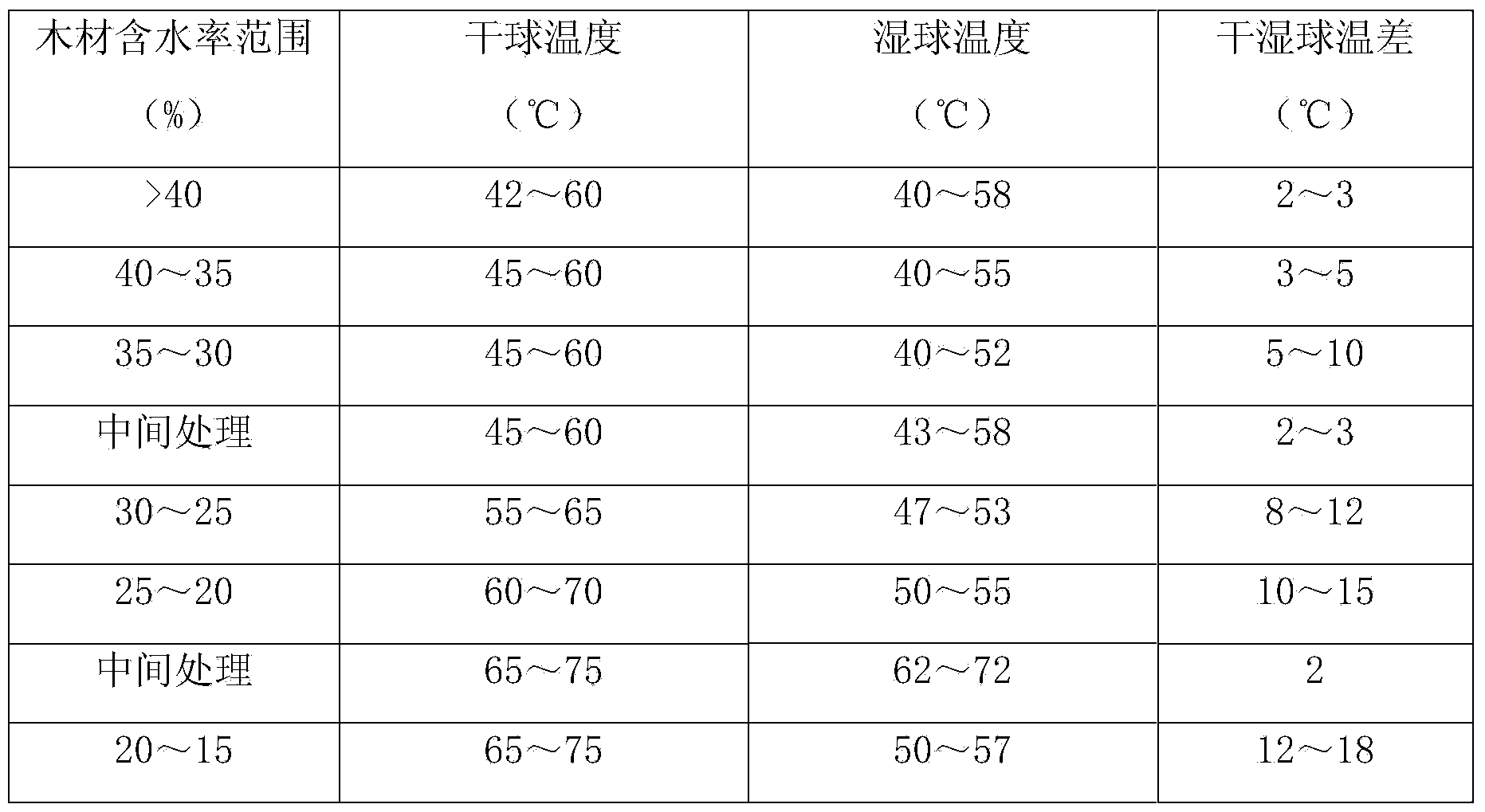

[0026] Example 1: 1) Drying of wood: put 30mm thick colored wood into a conventional drying kiln, complete the drying of wood according to the drying standards in Table 3, and make the final moisture content of wood reach 8% to 10%.

[0027] Table 3 Wood Drying Benchmarks

[0028]

[0029] Note: The intermediate processing time is 5-6 hours.

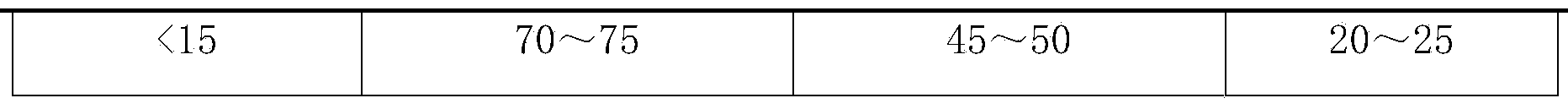

[0030] 2) Microporous treatment of hard miscellaneous wood and anoxic high temperature treatment of hard miscellaneous wood: After completing step 1), soak the dried wood in 7% nickel acetate aqueous solution (catalytic activator) for 8-10 minutes, take out Finally, according to the requirements of wood anoxic treatment, the wood impregnated with nickel acetate is loaded into the wood anoxic high-temperature treatment kiln, and the wood anoxic high-temperature treatment is completed according to the treatment process in Table 4.

[0031] Table 4 wood anoxic high temperature treatment process

[0032]

[0033]

[0034] 3) Color...

Embodiment 2

[0036] Example 2: 1) Drying of wood: put 30mm thick colored wood into a conventional drying kiln, complete the drying of wood according to the drying standards in Table 3, and make the final moisture content of wood reach 8% to 10%.

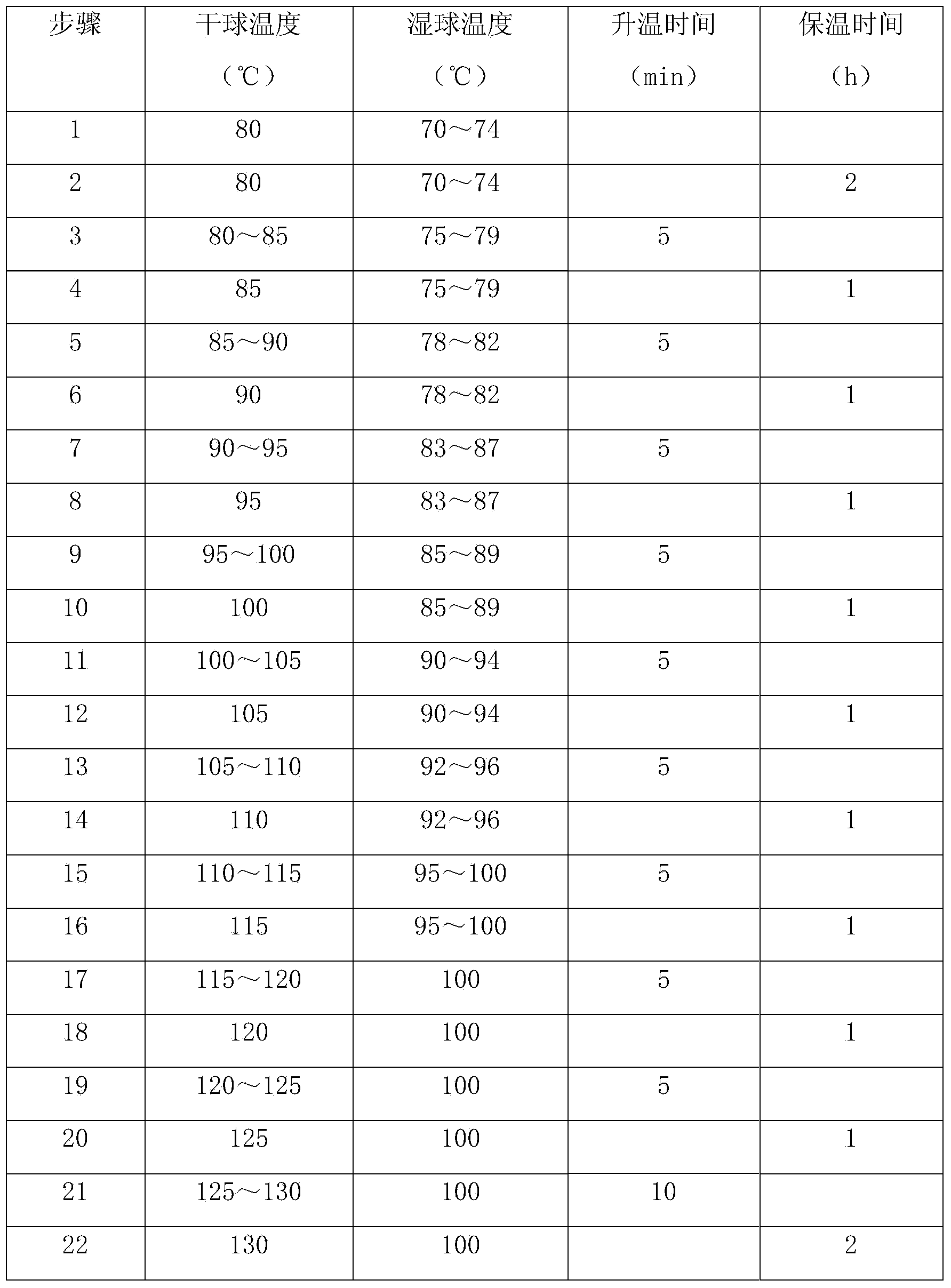

[0037] 2) Microporous treatment of hard miscellaneous wood and anoxic high temperature treatment of hard miscellaneous wood: After completing step 1), immerse the dried wood in 7% nickel acetate aqueous solution (catalytic activator) for 8-10 minutes, take out Finally, according to the requirements of wood anoxic treatment, the wood impregnated with nickel acetate is packed into the wood anoxic high-temperature treatment kiln, and the treatment process is completed according to the treatment process of table 4 before step 35; from step 36, it is processed according to table 5 Process complete wood anoxic high temperature treatment

[0038] Table 5 wood anoxic high temperature treatment process

[0039]

[0040]

[0041] 3) Color space meas...

Embodiment 3

[0043] Example 3: 1) Drying of wood: put 30 mm thick colored wood into a conventional drying kiln, complete the drying of wood according to the drying standards in Table 3, and make the final moisture content of wood reach 8% to 10%.

[0044] 2) Microporous treatment of hard miscellaneous wood and anoxic high temperature treatment of hard miscellaneous wood: After completing step 1), immerse the dried wood in 7% nickel acetate aqueous solution (catalytic activator) for 8-10 minutes, take out Finally, according to the requirements of wood anoxic treatment, the wood impregnated with nickel acetate is packed into the wood anoxic high-temperature treatment kiln, and the treatment process is completed according to the treatment process of table 4 before step 35; from step 36, it is processed according to table 7 Process complete wood anoxic high temperature treatment

[0045] Table 6 wood anoxic high temperature treatment process

[0046]

[0047] 3) Color space measurement of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com