Alcohol-free alkaline texturing solution for mono-crystalline silicon wafer, texturing method for mono-crystalline silicon wafer, solar cell and manufacturing method for solar cell

A technology for solar cells and monocrystalline silicon wafers, applied in the field of solar cells, can solve the problems of unqualified corrosion depth, non-uniformity, and high requirements for airtightness, so as to increase the absorption of light, enhance anisotropy, and improve conversion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

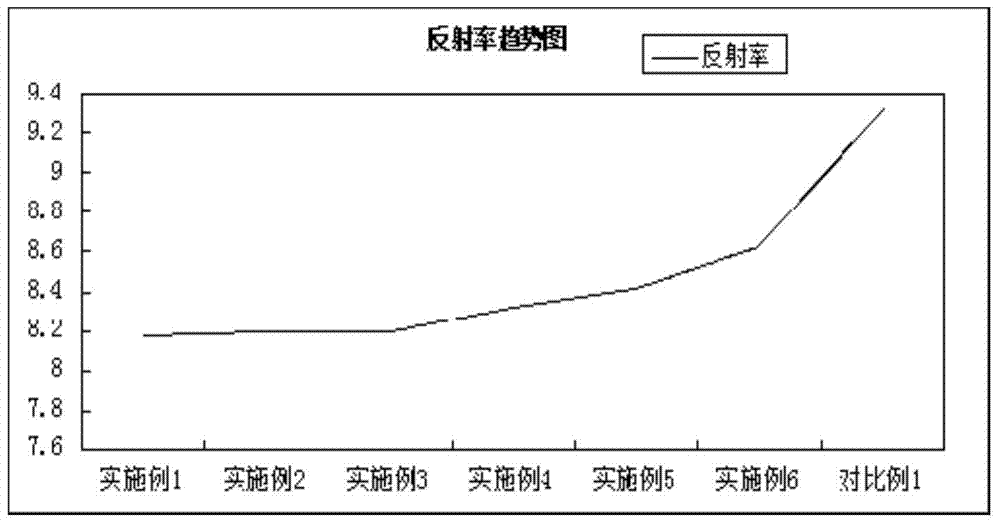

Embodiment 1

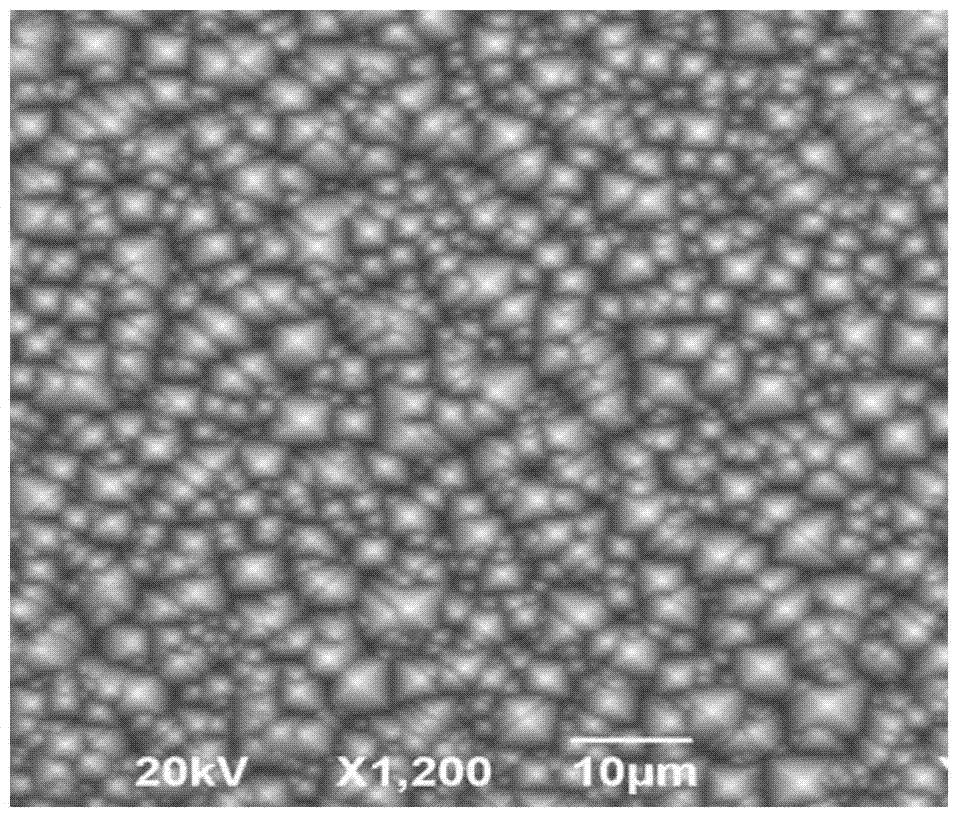

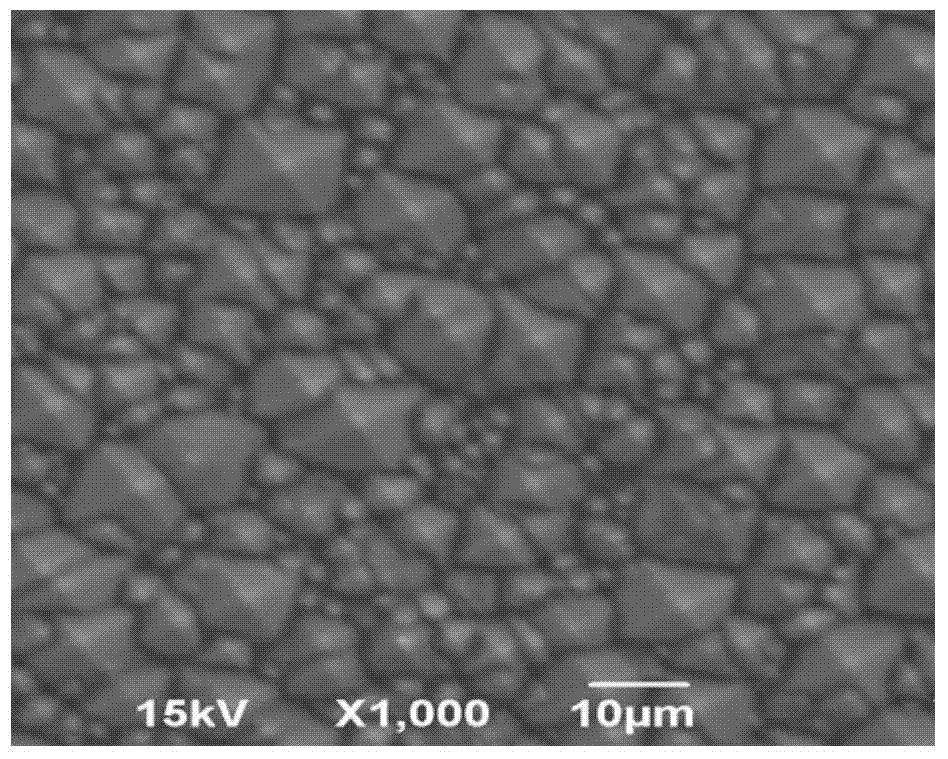

[0041] Dissolve 50ml of sodium hydroxide solution with a mass percentage concentration of 46% and 10ml of alcohol-free additives (the model is TS42, provided by Changzhou Shichuang Energy Technology Co., Ltd.) in deionized water to prepare an alcohol-free alkaline texturing solution, wherein The mass percentage concentration of the sodium hydroxide solution is 4%, and the mass percentage concentration of the alcohol-free additive solution is 0.5%.

[0042] Using a mixture of hydrogen peroxide and sodium hydroxide (V 双氧水 :V 氢氧化钠 :V 水 =1.5:7:115) Pre-clean the monocrystalline silicon wafer after diamond wire cutting for 3 minutes, and then wash it with water for 3 minutes. After washing, the monocrystalline silicon wafer enters the surface of the texturing tank containing the above alcohol-free alkaline texturing solution Texturing is maintained for 17 minutes, and the temperature of the alkaline texturing solution is 80°C.

[0043] The monocrystalline silicon chip after the ...

Embodiment 2

[0045] Dissolve 50ml of sodium hydroxide solution with a mass percentage concentration of 46% and 10ml of alcohol-free additives (the model is TS42, provided by Changzhou Shichuang Energy Technology Co., Ltd.) in deionized water to prepare an alcohol-free alkaline texturing solution, wherein The mass percentage concentration of the sodium hydroxide solution is 3%, and the mass percentage concentration of the alcohol-free additive solution is 0.4%.

[0046] Using a mixture of hydrogen peroxide and sodium hydroxide (V 双氧水 :V 氢氧化钠 :V 水 =1.5:7:115) Pre-clean the monocrystalline silicon wafer after diamond wire cutting for 5 minutes, and then wash it with water for 5 minutes. After washing, the monocrystalline silicon wafer enters the surface of the texturing tank containing the above alcohol-free alkaline texturing solution Texturing is maintained for 13 minutes, and the temperature of the alkaline texturing solution is 90°C.

[0047] The monocrystalline silicon chip after the ...

Embodiment 3

[0049] Dissolve 50ml of sodium hydroxide solution with a mass percentage concentration of 46% and 10ml of alcohol-free additives (the model is TS42, provided by Changzhou Shichuang Energy Technology Co., Ltd.) in deionized water to prepare an alcohol-free alkaline texturing solution, wherein The mass percent concentration of the sodium hydroxide solution is 5%, and the mass percent concentration of the alcohol-free additive solution is 0.65%.

[0050] Using a mixture of hydrogen peroxide and sodium hydroxide (V 双氧水 :V 氢氧化钠 :V 水 =1.5:7:115) Pre-clean the monocrystalline silicon wafer after diamond wire cutting for 5 minutes, and then wash it with water for 5 minutes. Hold for 13 minutes, the temperature of the alkaline texturing solution is 85°C.

[0051] The monocrystalline silicon chip after the texturing enters in the washing tank and washes for 5 minutes, then is sent into the pickling tank that fills 40wt% hydrofluoric acid and 30wt% hydrochloric acid mixed solution (th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com