Water-resistant and high temperature-resistant polymer latex and preparation method thereof

A technology of high temperature resistant polymer and latex, applied in coating, paper coating, textile and papermaking, etc., can solve the problems of water resistance and high temperature resistance of finished paper, and achieve excellent water resistance and high temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

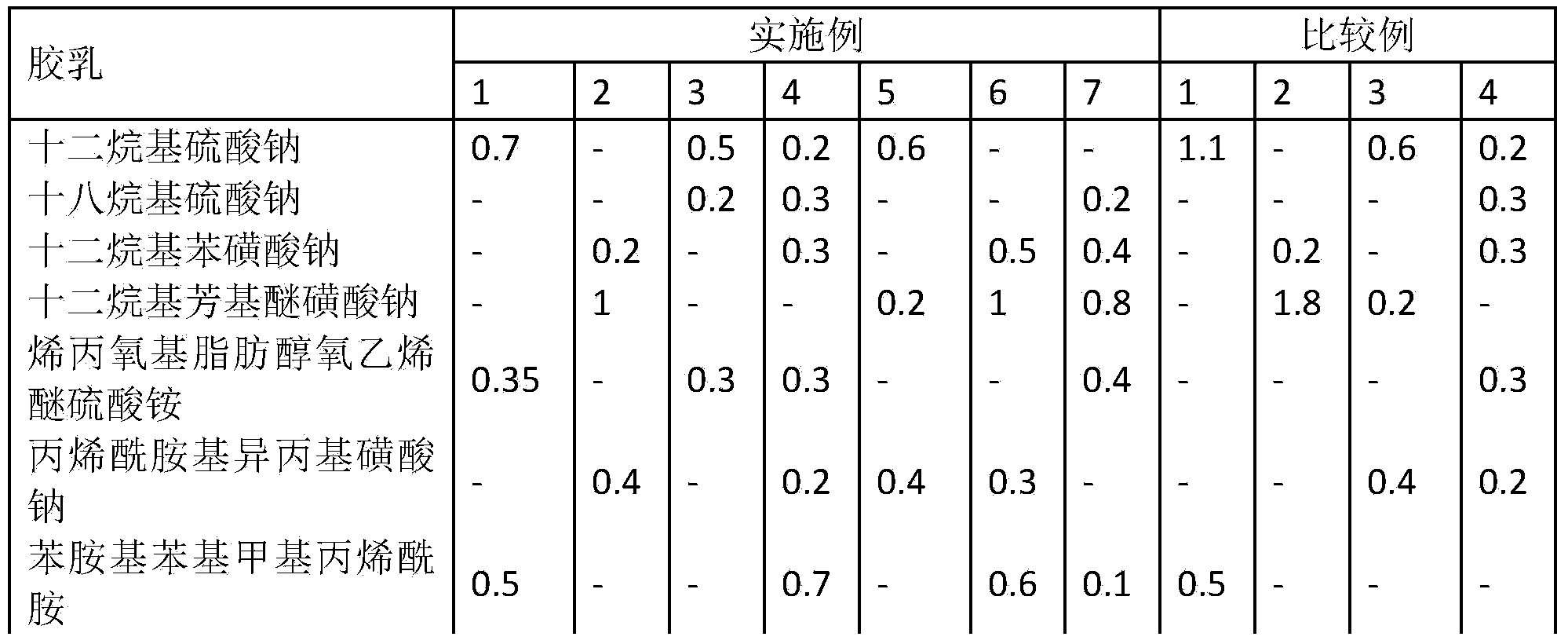

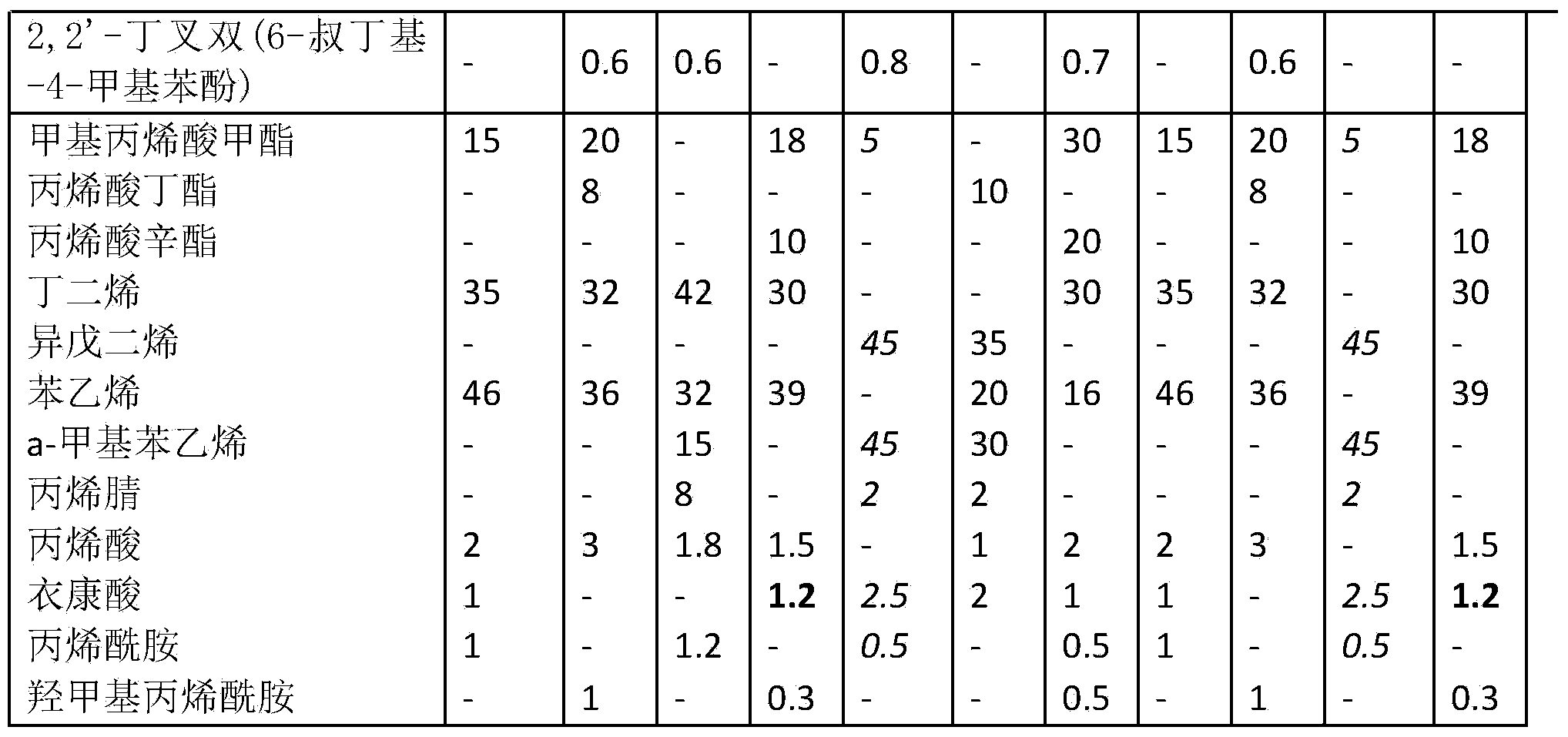

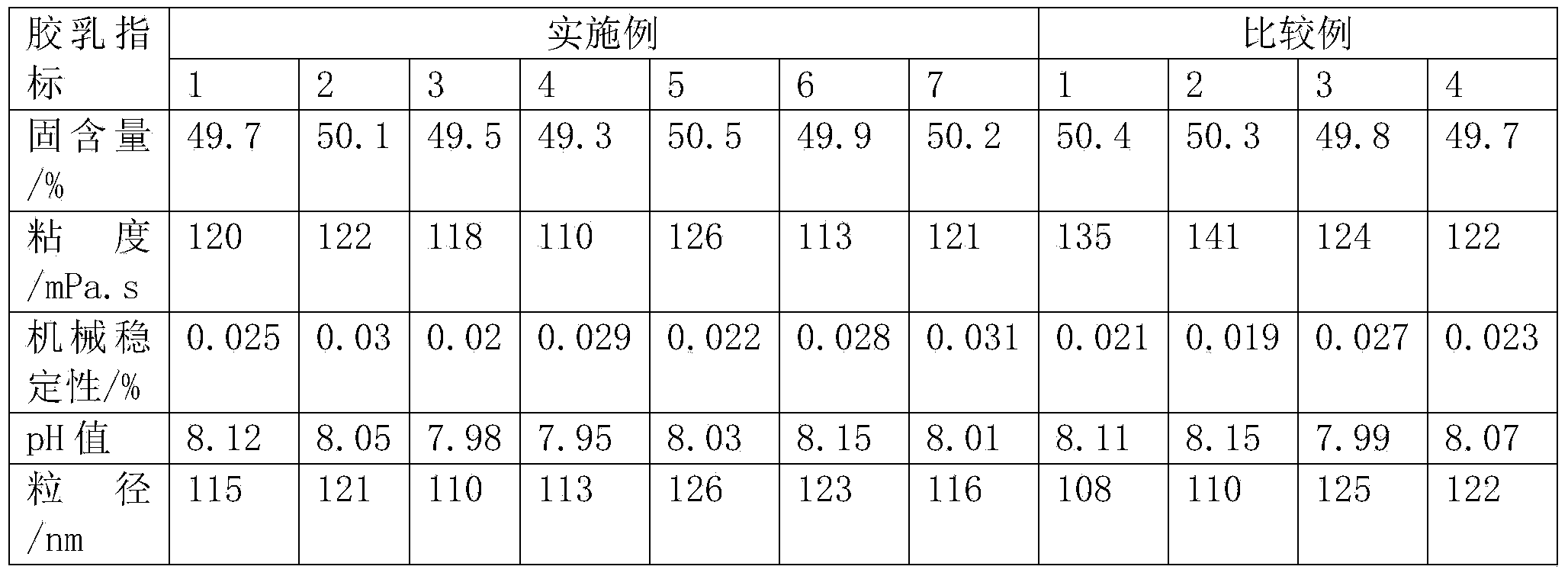

Examples

Embodiment 1

[0025] Embodiment 1 (in total monomer addition is 100wt%):

[0026] First vacuumize the 50L polymerization kettle, and then replace it with nitrogen. When the vacuum reaches -0.08MPa, add 70wt% of water, 0.4wt% of sodium lauryl sulfate, and 0.35wt of allyloxy fatty alcohol oxyethylene ether ammonium sulfate. %, potassium chloride 0.06wt%, sodium hydroxide 0.86wt%, methyl methacrylate 3wt%, styrene 12wt%, tertiary dodecyl mercaptan 0.3wt%, acrylic acid 2wt%, itaconic acid 1wt%, propylene Amide 1wt%, butadiene 10wt%, then start to stir and heat up to 70 degrees, add initiator ammonium persulfate 1.5wt% to maintain polymerization after 1 hour, with water 30wt%, sodium lauryl sulfate 0.3wt%, A mixture of 0.2wt% tertiary dodecyl mercaptan, 34wt% styrene, 0.5wt% anilinophenyl methacrylamide, 25wt% butadiene, and 12wt% methyl methacrylate was added continuously within 4 hours and then matured After 3 hours, the polymerization conversion rate reached over 98%. Add appropriate amount ...

Embodiment 2

[0027] Embodiment 2 (in total monomer addition is 100wt% meter)

[0028] First vacuumize the 50L polymerization kettle, and then replace it with nitrogen. When the vacuum reaches -0.08MPa, add 100wt% water, 1.0wt% sodium dodecyl aryl ether sulfonate, and 0.2wt% sodium dodecylbenzenesulfonate %, Sodium acrylamido isopropylsulfonate 0.4wt%, Potassium chloride 0.05wt%, Sodium hydroxide 0.2wt%, Butyl acrylate 8wt%, 2,2'-Butylidene bis(6-tert-butyl -4-methylphenol) 0.6wt%, styrene 36wt%, tertiary dodecyl mercaptan 0.5wt%, acrylic acid 3wt%, methyl methacrylate 20wt%, methylol acrylamide 1wt%, butadiene, 32wt%, then start to stir and heat up to 65 degrees, add initiator ammonium persulfate 1.0wt% polymerization reaction for 8 hours, the conversion rate is over 98%, add appropriate amount of potassium hydroxide and defoamer and other auxiliary agents to remove residual monomer Body, see Table 2 for latex technical indicators, and Table 3 for latex impregnated paper technical indicat...

Embodiment 3

[0029] Embodiment 3 (in total monomer addition is 100wt% meter)

[0030] First vacuumize the 50L polymerization kettle, and then replace it with nitrogen. When the vacuum reaches -0.08MPa, add 80wt% of water, 0.2wt% of sodium octadecyl sulfate, and 0.3wt of allyloxy fatty alcohol oxyethylene ether ammonium sulfate. %, potassium chloride 0.06wt%, sodium hydroxide 0.83wt%, a-methylstyrene 15wt%, tertiary dodecyl mercaptan 0.3wt%, acrylic acid 1.8wt%, acrylonitrile 8wt%, acrylamide 1.2wt% , butadiene 12wt%, then start to stir and heat up to 70 degrees, add initiator ammonium persulfate 1wt%, maintain polymerization reaction for 1 hour and then add water 20wt% continuously, sodium lauryl sulfate 0.5wt%, t-dodecyl Carbon mercaptan 0.2wt%, ammonium persulfate 0.2wt%, 2,2'-butylene bis(6-tert-butyl-4-methylphenol) 0.6wt%, styrene 32wt%, butadiene 30wt% The mixture continued to polymerize for 4 hours, and the polymerization conversion rate reached more than 98%. A proper amount of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com