a ta 2 o 5 /zno/hfo 2 Asymmetric double-heterojunction light-emitting diode and preparation method thereof

A light-emitting diode and double heterojunction technology, which is applied in the field of nanomaterials and optoelectronic devices, can solve the problems affecting the luminous performance of the device, the luminous intensity is not high, and limit the practical application, so as to achieve the optimization of material preparation process, improve the luminous efficiency, and achieve good results. The effect of current spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Substrate cleaning: Use p-type GaN grown on sapphire as the substrate, cut it into a size of 15mm×15mm, ultrasonically clean it with acetone, alcohol, and deionized water for 5 minutes, and finally dry it with a nitrogen gun.

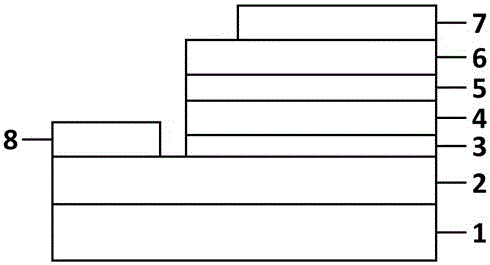

[0024] 2. Ta 2 o 5 / ZnO / HfO 2 Growth of asymmetric double heterojunction: put the cleaned substrate into the growth chamber of the RF magnetron sputtering system, and pump the growth chamber to a background vacuum of 5×10 -4 Pa, the substrate is heated until its temperature reaches 200°C. Choose HfO 2 Ceramic target, ZnO ceramic target and Ta metal target were used as the preparation of HfO 2 thin film, intrinsic ZnO thin film and Ta 2 o 5 Thin film targets. Before coating each layer of film, it was pre-sputtered for 10 min to remove impurities on the target surface. Using the method of radio frequency magnetron sputtering, HfO is first deposited on the p-type GaN substrate 2 Thin film, the deposition substrate temperature is 200°C, ...

Embodiment 2

[0029] 1. Substrate cleaning: Use p-type GaN grown on sapphire as the substrate, cut it into a size of 15 mm×15 mm, ultrasonically clean it with acetone, alcohol, and deionized water for 5 minutes, and finally dry it with a nitrogen gun .

[0030] 2. Ta 2 o 5 / ZnO / HfO 2 Growth of asymmetric double heterojunction: put the cleaned substrate into the growth chamber of the RF magnetron sputtering system, and pump the growth chamber to a background vacuum of 1×10 -3 Pa, the substrate is heated until its temperature reaches 300°C. Choose HfO 2 Ceramic target, ZnO ceramic target and Ta metal target were used as the preparation of HfO 2 thin film, intrinsic ZnO thin film and Ta 2 o 5 Thin film targets. Before coating each layer of film, it was pre-sputtered for 10 min to remove impurities on the target surface. Using the method of radio frequency magnetron sputtering, HfO is first deposited on the p-type GaN substrate 2 Thin film, the deposition substrate temperature is 300...

Embodiment 3

[0035] 1. Substrate cleaning: Use p-type GaN grown on sapphire as the substrate, cut it into a size of 15 mm×15 mm, ultrasonically clean it with acetone, alcohol, and deionized water for 5 minutes, and finally dry it with a nitrogen gun .

[0036] 2. Ta 2 o 5 / ZnO / HfO 2 Growth of asymmetric double heterojunction: put the cleaned substrate into the growth chamber of the RF magnetron sputtering system, and pump the growth chamber to a background vacuum of 1×10 -3 Pa, the substrate is heated until its temperature reaches 300°C. Choose HfO 2 Ceramic target, ZnO ceramic target and Ta metal target were used as the preparation of HfO 2 thin film, intrinsic ZnO thin film and Ta 2 o 5 Thin film targets. Before coating each layer of film, it was pre-sputtered for 10 min to remove impurities on the target surface. Using the method of radio frequency magnetron sputtering, HfO is first deposited on the p-type GaN substrate 2 For thin film, the deposition substrate temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com