Method for refining petrobenzene and thiophene by using ionic liquid complex solvent

A technology of ionic liquid and composite solvent, which is applied in extraction and purification/separation, organic chemistry, bulk chemical production, etc. It can solve the problems of inability to process acid tar and waste residue, complex catalytic hydrogenation process, and low efficiency of thiophene recovery. Remarkable energy saving effect, low steam pressure, and reduced benzene loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

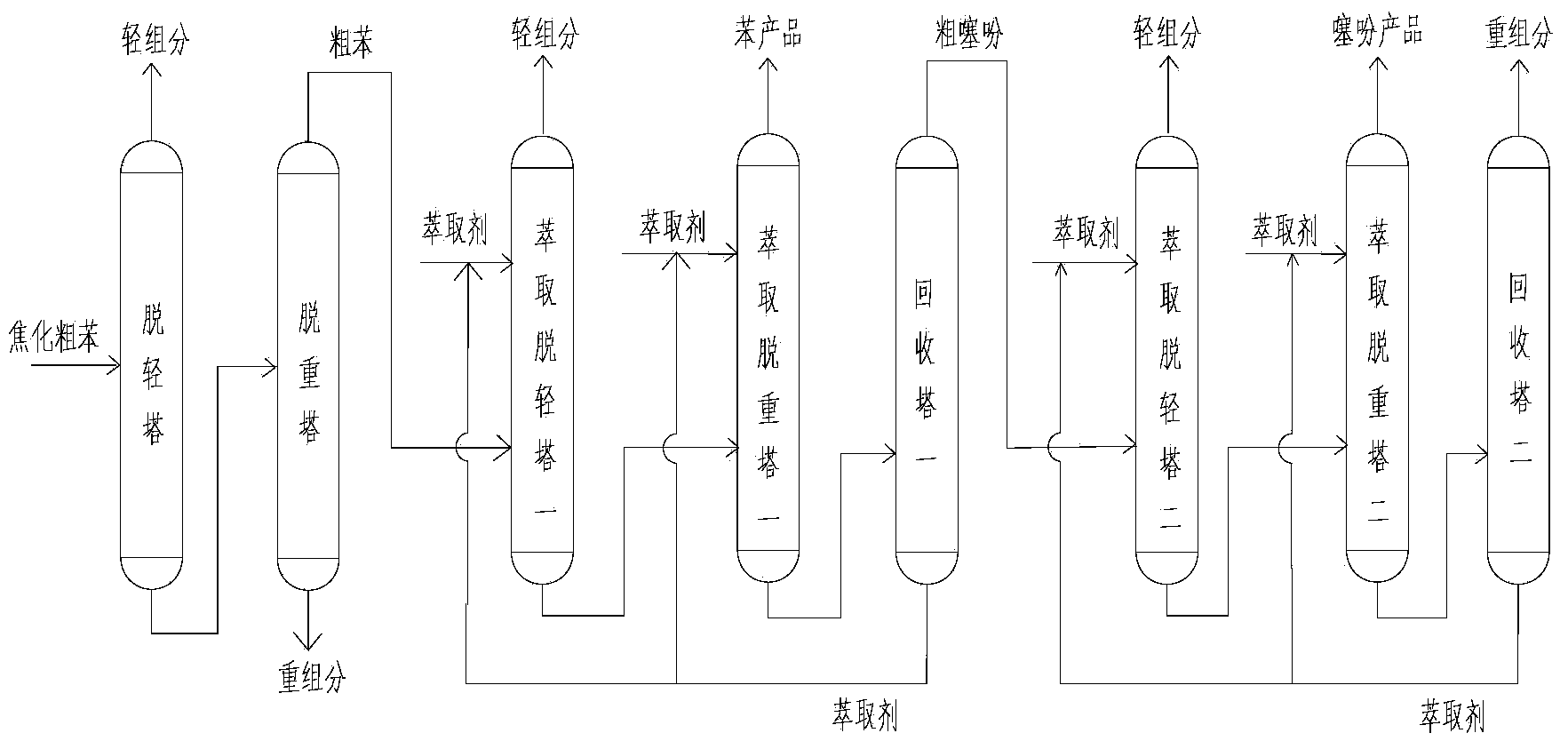

[0023] Attached figure 1 The process flow shown uses coking crude benzene produced by a coking plant as raw material, and the composition is: 64.8% benzene (mass content, the same below), 5.2% thiophene, and the rest are light and heavy components.

[0024] Pretreatment process:

[0025] (1) Coking crude benzene first removes light components in the light removal tower. The operating pressure of the light removal tower is 101kPa, the temperature at the top of the tower is 80°C, and the temperature of the bottom of the tower is 100°C. Light components with a boiling point lower than benzene are extracted from the top of the tower , mainly H2S, CS2, pentene, methylethylene, cyclopentane, hexene, hexane, methylcyclopentane and other unsaturated hydrocarbons.

[0026] (2) The material from the tower tank of the light removal tower enters the weight removal tower to remove heavy components. The operating pressure of the weight removal tower is 50kPa, the temperature at the top of ...

Embodiment 2

[0036] Attached figure 1 Shown technological process, raw material is with embodiment 1.

[0037] Pretreatment process:

[0038] (1) Coking crude benzene first removes light components in the light removal tower. The operating pressure of the light removal tower is 50kPa, the temperature at the top of the tower is 50°C, and the temperature of the bottom of the tower is 90°C. Light components with a boiling point lower than benzene are extracted from the top of the tower, mainly It is unsaturated hydrocarbons such as H2S, CS2, pentene, methylethylene, cyclopentane, hexene, hexane, methylcyclopentane, etc., and the materials in the tower reactor enter the de-weighting tower;

[0039] (2) The material from the tower tank of the light removal tower enters the weight removal tower to remove heavy components. The operating pressure of the weight removal tower is 101kPa, the temperature at the top of the tower is 85°C, and the temperature of the tower tank is 105°C. The heavy compon...

Embodiment 3

[0049] The raw materials and operation steps are the same as in Example 1. The ionic liquid composite solvent is a composite solvent composed of 1-octyl-3-methylimidazole trifluorosulfonate and N-formylmorpholine at a mass ratio of 3:1, and the solvent ratio is 1 : 1, obtain 99.99% benzene product, its index such as color number, bromine value, crystallization point, sulfur and nitrogen impurity content all reach the petroleum benzene national standard primary standard, can replace petroleum benzene to use. The thiophene refining process yields 99.8% thiophene products with a recovery rate of 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com