Hydrophobic UV (ultraviolet) curing paint

A technology of ultraviolet light and curing paint, which is applied in coatings, epoxy resin coatings, polyester coatings, etc., can solve the problems of poor physical and mechanical properties of microporous films, stability of polar material surface adhesion, and harsh implementation conditions And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

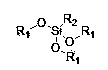

[0033] Preparation of silane modified resin:

[0034] Add 42% bisphenol A epoxy acrylate and 55% difunctional polyester acrylate into a closed container with reflux condenser and stirrer, then raise the temperature of the system to 55°C, add 3% silane coupling agent, Stir and reflux for 10 h to obtain the silane-modified resin. The hydroxyl value of the difunctional polyester acrylate is 70-100 mgKOH / g.

[0035] A kind of hydrophobic UV-curable paint, by weight percentage:

[0036] Silane modified resin 43%; Isobornyl methacrylate 8%; Alkoxylated phenol acrylate 8%; 3,3,5-trimethylcyclohexane methacrylate 8%; 184 1%; TPO 1% ; Acetone 29%; BYK354 1%; BYK141 1%.

Embodiment 2

[0038] Preparation of silane modified resin:

[0039] Add 45% bisphenol A epoxy acrylate and 50% difunctional polyester acrylate into a closed container with reflux condenser and agitator, then raise the temperature of the system to 60°C, add 5% silane coupling agent, Stir and reflux for 8 hours to obtain the silane-modified resin. The hydroxyl value of the difunctional polyester acrylate is 70-100 mgKOH / g.

[0040] A kind of hydrophobic UV-curable paint, by weight percentage:

[0041] Silane modified resin 28%; Isobornyl methacrylate 9%; Alkoxylated phenol acrylate 8%; 3,3,5-trimethylcyclohexane methacrylate 10%; 184 0.5%; TPO 1.5% ; Butyl acetate 40%; BYK354 1%; BYK141 1%.

Embodiment 3

[0043] Preparation of silane modified resin:

[0044] Add 54% bisphenol A epoxy acrylate and 39% difunctional polyester acrylate into a closed container with reflux condenser and agitator, then raise the temperature of the system to 65°C, add 7% silane coupling agent, Stir and reflux for 5.5 hours to obtain the silane-modified resin. The hydroxyl value of the difunctional polyester acrylate is 70-100 mgKOH / g.

[0045] A kind of hydrophobic UV-curable paint, by weight percentage:

[0046] Silane modified resin 50%; Isobornyl methacrylate 6%; Alkoxylated phenol acrylate 8%; 3,3,5-trimethylcyclohexane methacrylate 5%; 184 1%; TPO 1% ; Butanol 27%; BYK354 1%; BYK141 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com