Preparation method of high-stability neutral photocatalyst sol for cement-based material

A cement-based material, high stability technology, applied in the field of material science, can solve the problems of no detailed preparation of photocatalyst, poor sol crystallization performance, poor photocatalytic activity, etc., achieve good photocatalytic self-cleaning activity, good dispersion stability, Good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

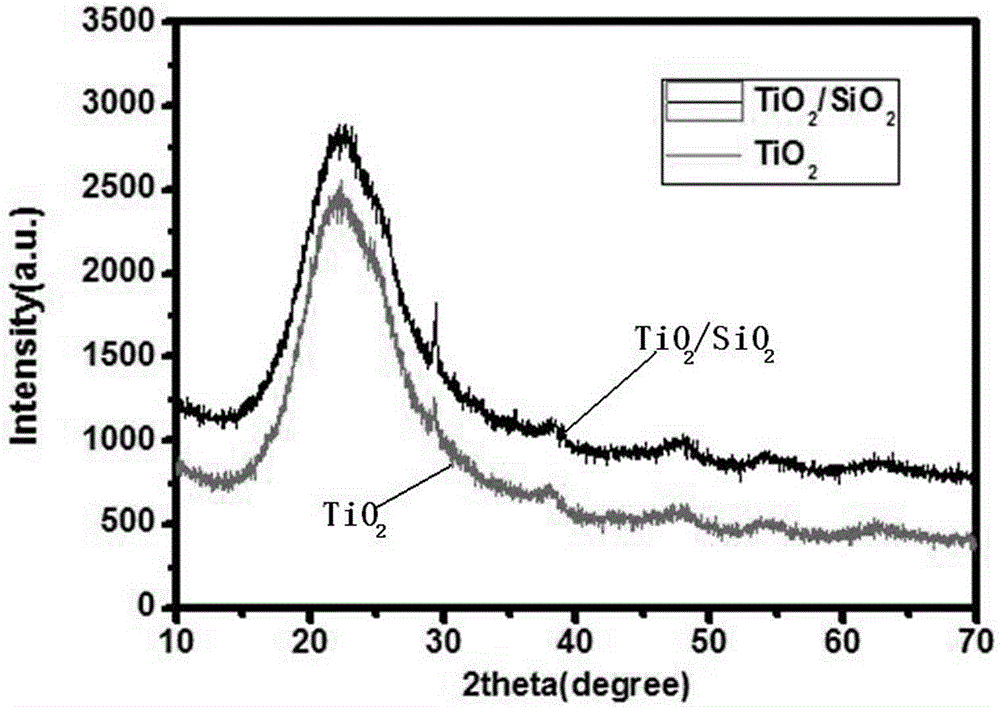

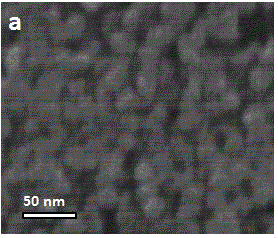

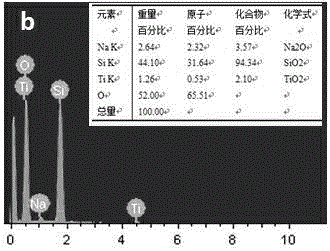

[0029] Example 1 TiO 2 / SiO 2 Preparation of composite hydrosol:

[0030] (1) TiO 2 Synthesis of acidic sol

[0031] Titanium sulfate was added to 100 mL of water to make a 0.2 M aqueous solution, and stirred for 1 h to obtain a clear and transparent solution. Then add a certain amount of 0.1M ammonia solution to adjustP H is about 7. After aging for a period of time, centrifuge, use deionized water to fully remove the sulfate in the solution three times (because the sulfate ion will cause precipitation to be removed), take out the filter cake, add some deionized water, and then Add a certain amount of dilute nitric acid solution, control its concentration to (10-20) wt %, adjust P H to around 1. then at 60 o C under stirring for 4-6 h, to obtain transparent TiO with blue light 2 Sol.

[0032] (2) SiO 2 Synthesis of Sol

[0033] In a cold water bath, take 2-4mL tetraethyl orthosilicate and add it to 40-50mL ethanol and stir for 10 min to make it fully mixed into a ho...

Embodiment 2

[0037] A certain amount of titanium tetrachloride was added to 100 mL of water to form a 0.2-0.5 M aqueous solution, and stirred for 1 h to obtain a clear and transparent solution. Then add a certain amount of 0.1M ammonia solution to adjust P H is about 7. After aging for a period of time, centrifuge and fully remove the Cl in the solution with deionized water three times - , take out the filter cake, add some deionized water, then add a certain amount of dilute hydrochloric acid solution, control its concentration to be 30-40wt%, adjust P H to around 1. Then stirred at 60 °C for 4-5 h to obtain transparent TiO with blue light 2 Sol. Take the prepared TiO 2 50 mL of the sol was placed in a beaker, and then 20 mL of the prepared SiO 2 After stirring the sol for 1 h, 1 M NaOH aqueous solution was added dropwise to it until the pH = 7, and the obtained sol was re-dispersed into 200 mL of isopropanol aqueous solution with a volume fraction of 50% to obtain a highly stable p...

Embodiment 3

[0039] A certain amount of titanyl sulfate was added to 100 mL of water to prepare a 0.2-0.4 M aqueous solution, and stirred for 1 h to obtain a clear and transparent solution. Then add a certain amount of 0.1M ammonia solution to adjust P H is about 7. After aging for a period of time, centrifuge and use deionized water to fully remove SO in the solution 3 times 4 2- , take out the filter cake, add some deionized water, then add a certain amount of dilute sulfuric acid solution, control its concentration to be 10-20wt%, adjust P H to around 1. Then stirred at 60 °C for 5-6 h to obtain transparent TiO with blue light 2 Sol. Take the prepared TiO 2 50 mL of the sol was placed in a beaker, and then 20 mL of the prepared SiO 2 After stirring the sol for 1 h, a 1M NaOH aqueous solution was added dropwise to it until the pH = 7, and the obtained sol was re-dispersed into 200 mL of a 40% ethanol aqueous solution with a volume fraction of 40% to obtain a highly stable photocat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com