Comprehensive utilization process for ageratina adenophora

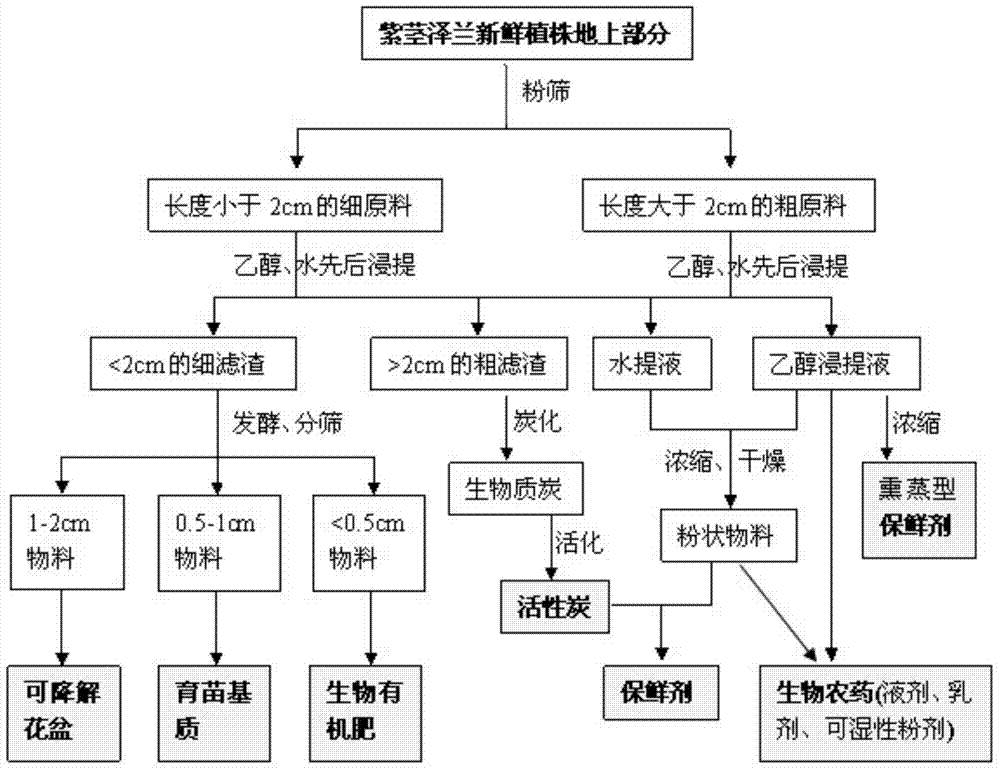

The invention relates to a technology of E. japonica and technology, which is applied to the new technological field of comprehensive development and utilization of E. pear and can solve the problems of difficulty in extracting chlorogenic acid, large differences in production cost and sales market, and reduction of chlorogenic acid content in leaves. , to achieve the effects of huge ecological and economic benefits, diverse product types, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Fresh plants of Eupatorium adenophorum (aboveground part) were harvested on the side of the road in Miyi County, Panzhihua City, Xichuan Province, with a weight of 1000kg. Immediately after harvesting, they were transported to the production workshop of Xiyu Biotechnology Co., Ltd., and used a powder sieving machine DYFS1.7* 560 carries out powder sieve, and the raw material 425kg that obtains minced length is less than 2cm, the raw material 560kg that length is more than 2cm. After that, put the two kinds of raw materials into the leaching tank respectively, compact them slightly, and first use the extract solution (containing 95% ethanol by weight and 0.1% urea by weight) to extract for 1-2 days. After filtration, adopt tap water leaching 1-2 day that is 3 times of raw material weight, then mix the extract solution of two kinds of raw materials respectively to obtain ethanol extract solution 4522kg, water extract solution 3015kg, obtain the filter residue 625kg that le...

Embodiment 2

[0055] Mix 2000kg of ethanol extract and 1515kg of water extract, carry out vacuum distillation at 60°C, recover 1820kg of ethanol, and obtain 162kg of concentrated solution. Mix 81kg of concentrate with 6kg of B-30 pesticide carrier stabilizer to make 87kg of water-based biopesticide. In addition, 81kg of concentrated liquid is mixed with 20kg of Nongru No. 500 liquid to make 101kg of emulsion type biological pesticide.

[0056] After mixing the remaining 2000 kg of ethanol extract and 1500 kg of water extract, carry out vacuum distillation at 60° C. to recover 1840 kg of ethanol to obtain 14 kg of powdery material. Mix 7 kg of powdery material with 1 kg of Nongru No. 500 solid to make 8 kg of wettable powder type biological pesticide. The emulsion type biopesticide and wettable powder biopesticide obtained in the present invention have remarkable control effects on plant diseases caused by aphids, bacteria, fungi and viruses.

Embodiment 3

[0058] Mix 560kg of filter residue with a length of less than 2cm, 2kg of calcium oxide, and 1,000kg of peat, and dissolve 38kg of urea in 400kg of tap water at a temperature of 26°C, and mix with the mixed material to make the water content of the mixed material reach 55%. Then use High-temperature microbial strains are fermented. The specific fermentation method is as follows: stack the mixed raw materials stirred by a mixer in a strip-shaped fermenter with a width of 2-2.5m and a height of 1-1.5m. The added high-temperature microbial strains are Rw decay accelerator (provided by Henan Hebi Renyuan Biological Co., Ltd.), and the dosage is 0.2kg. When using, mix the microbial strains with 2kg of peat and mix them into the mixture. Stack for 1-3 days, measure the fermentation temperature at 12 o'clock in the morning and 2 o'clock in the afternoon every day, and the depth of the thermometer inserted is 15cm. After the fermentation temperature rises above 60°C, use the compost ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com