Macroelement solid water-soluble fertilizer and preparation method thereof

A technology with a large amount of elements and solid water, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of large market application limitations, complex process, high product price, etc., to achieve convenient storage and transportation, simple production process, Fast dissolving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

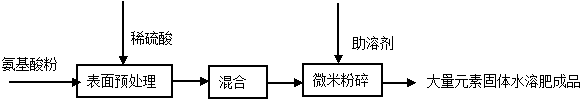

Image

Examples

Embodiment 1

[0034] Example 1. The components and ratios of macroelement solid water-soluble fertilizers are as follows, all in percentages by weight:

[0035] Urea 34%, potassium nitrate 13%, ammonium phosphate 16%, dipotassium hydrogen phosphate 18%, boric acid 2%, magnesium sulfate 2%, zinc sulfate 1.5%. 0.5% copper sulfate, 1% manganese sulfate, 6% amino acid powder, 4% high-efficiency dispersant, 2% co-solvent, and the proportion of each group of high-efficiency dispersant is: polystyrene sulfonate : Dimethyldienyl ammonium chloride : Sulfomethyl polyacrylamide : Polyoxyethylene-propylene oxide block copolymer=1:1:1:1, co-solvent is polyvinylpyrrolidone.

[0036] The preparation method is as follows:

[0037] Add amino acid powder with a weight percentage of 5%~10% into a high-speed mixer, then add dilute sulfuric acid accounting for 5%~10% of amino acid powder, and carry out surface treatment on the amino acid powder at a speed of 100r / min. Put the amino acid powder into th...

Embodiment example 2

[0039] Implementation case 2. As described in embodiment case 1, its difference is that each raw material component is as follows, is weight percent:

[0040] Urea 30%, potassium nitrate 15%, ammonium phosphate 12%, dipotassium hydrogen phosphate 18%, boric acid 3%, magnesium sulfate 2%, zinc sulfate 1.5%. 0.5% copper sulfate, 1% manganese sulfate, 5% amino acid powder, 5% high-efficiency dispersant, 2% co-solvent, and the composition ratio of high-efficiency dispersant is: polystyrene sulfonate : Dimethyldienyl ammonium chloride : Sulfomethyl polyacrylamide : Polyoxyethylene-propylene oxide block copolymer=1:1:1:2, co-solvent is polyvinylpyrrolidone.

Embodiment example 3

[0041] Implementation case 3. As described in embodiment case 1, its difference is that each raw material component is as follows, is weight percent:

[0042] Urea 35%, potassium nitrate 12%, ammonium phosphate 14%, dipotassium hydrogen phosphate 14%, boric acid 4%, magnesium sulfate 2%, zinc sulfate 1.5%. Copper sulfate 0.5%, manganese sulfate 1%, amino acid powder 8%, high-efficiency dispersant 6%, co-solvent 2%, and the composition ratio of high-efficiency dispersant is: polystyrene sulfonate : Dimethyldienyl ammonium chloride : Sulfomethyl polyacrylamide : Polyoxyethylene-propylene oxide block copolymer=2:1:1:2, co-solvent is polyvinylpyrrolidone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com